Piezoelectric Pressure Sensor Variants Improve Process Quality

Meusburger presents two charge transfer versions, the single and coaxial cables with matching multi-channel connectors for cavity pressure sensors.

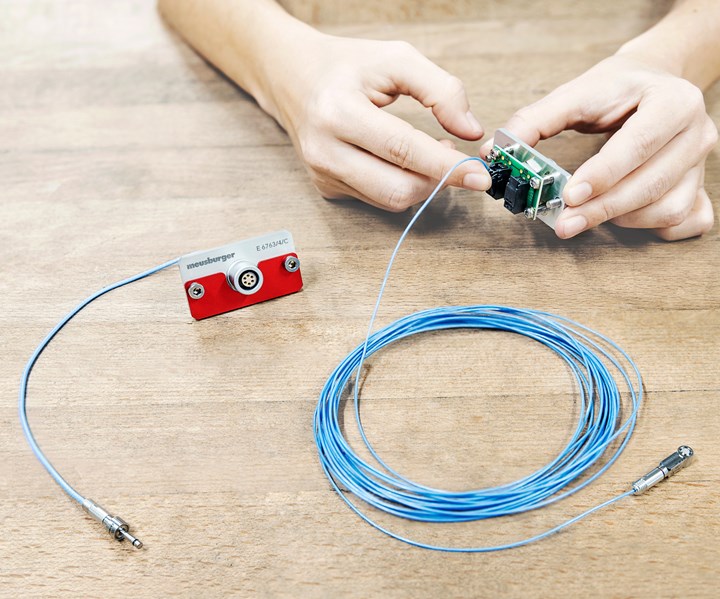

In addition to its existing range of cavity pressure sensors for plastic injection molding process monitoring, Meusburger now offers two charge transfer versions, the single wire E 6760 and the E 6757 mini coaxial cables, as well as matching multi-channel connectors for optimal process quality and increased part sustainability.

With a cable wire diameter of 1.2 mm, the single wire cable is ideal for molds with limited space. The wire can be routed flexibly with minimal bending radii, but may kink if not careful. Available in lengths of 2,000 and 5,000 mm, the single wire variant allows for shortening if required. Installation is effortless as a result of the insulation displacement connector on the multi-channel connector.

The E 6757 coaxial cable is characterized by optimal shielding against external signals due to its steel sheath, making it ideal for molds with a high number of electrical components such as hot runner components or monitoring equipment, or if the cable is routed outside of the mold. With a cable diameter of 1.9 mm, the coaxial wire is less flexible, but less prone to kinking, and is available in consecutive lengths from 200 to 1,000 mm. With Meusburger’s mini coaxial version, several sensor signals can be combined on one multi-channel connector.

The company’s offering of matching E 6763 multi-channel connectors, enables high process reliability during mold changes via a mold recognition chip integrated on the circuit board, and easy sensor data identification. Meusburger says the signals from 4 to 8 cavity pressure sensors can be combined with minimum cabling effort. Depending on the version, the multi-channel connectors also have insulation displacement contacts for the single wire cable (version S) and mini coax female connectors for the mini coaxial cable (version C).

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.