StackTeck Adds New FastTrack Mold Configurations

StackTeck Systems Ltd. announces the addition of 12- and 16-cavity mold configurations available for lids and round containers offered within the FastTrack program.

Share

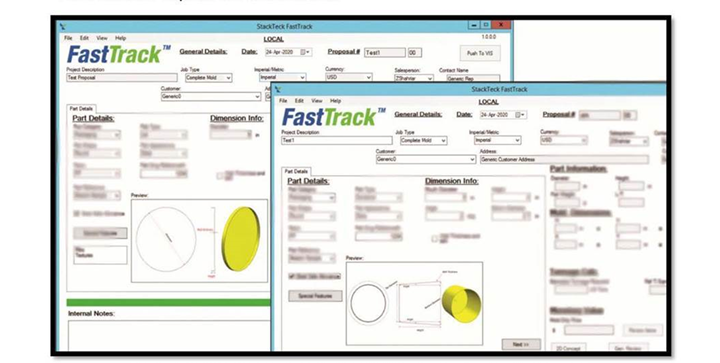

StackTeck Systems Ltd. announces the addition of 12- and 16-cavity mold configurations available for lids and round containers offered within the FastTrack program. The company’s FastTrack approach consists in the offering of fast mold deliveries, using automated design capabilities that work with a pre-set, optimized set of mold design rules. As compared with custom designed molds, the engineering phase of every project is reduced three to four weeks to just a few days. StackTeck offers single face molds for round lids and round air eject containers with 2, 4, 5, 6, 12, and 16 cavities.

The company can manufacture all major mold components in house, which avoids potential logistical risks. According to President and CEO Vince Travaglini, “Today many of our customers are directing us to keep our supplier base local, as part of the overall onshoring trend, to eliminate ‘surprises’. This approach can be followed entirely for FastTrack molds. For any converter in the Americas, this is the surest way to add capacity in a big hurry.”

Some of the most important advantages of FastTrack include rapid mold configuration, significantly reduced quoting and lead times, immediate feedback to customers of possible design difficulties and a range of options available in price, size, layouts and machine configurations. It also offers optimal mold size and cavitation to fit a particular injection molding machine, as well as faster customer response and mold deliveries.

The company’s Vice President of Sales, Simon Martin, explains, “With our FastTrack approach, we are able to provide mold concept diagrams to customers that are in current need of fast deliveries, allowing us to have formal proposals in their hands within one business day. Account managers can generate specific mold sizes and configurations in only a few minutes, helping customers find an optimal mold setup. Responding to customers’ needs during the global pandemic, we offer full on remote access and interactions that result in fast proposals, approvals and production molds running at their plants in a shorter amount of time.”