North American Tooling Spend Forecasted to Reach $8.3 Billion in 2025

Recent automaker profits are funding an increased number of new vehicle launches over the next few years, according to Harbour Results’ latest in-depth study, which in turn is expected to drive up tooling spend growth.

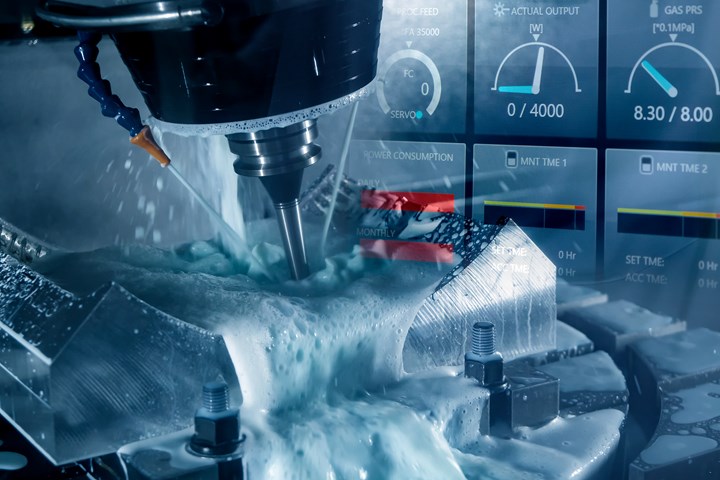

Five-axis CNC milling machine and monitor gauge cutting tire mold parts via solid ball end mill tools. Photo Credit: Getty Images

Harbour Results Inc. (HRI) recently released the results of the Harbour IQ in-depth study on the current state of the automotive vendor tooling industry. The analysis indicates automotive vendor tooling spend in North America will increase year-over-year at a rate of 13.4%, resulting in $8.3 billion in spending in 2025, a significant increase from 2022 estimated spend of $5.7 billion.

Several key factors are driving up the tooling spend growth. First, despite a drop in North American vehicle demand from 15.8 million to 13.7 units, most automakers are experiencing record levels of profit per vehicle sold. This strong performance is funding investment in technology and new vehicles. From 2023-2029 the number of vehicle nameplates in the region will grow 18% from 210 to 249. Additionally, battery-electric vehicle (BEV) nameplates are expected to grow from 20% of the mix in 2023, to 46% of the mix in 2029. New nameplates generate new vehicle launches, which require more tools. Furthermore, the Detroit Three automakers, who source most of their tools in this region, are planning to source tooling for all new full-sized pickup trucks and SUVs in 2024/2025 and 2026, which significantly increases the tooling demand. The Harbour IQ study shows that the discrete number of tools will increase by 14% CAGR from 2022 to 2025, driving more demand for tooling with all of the new models.

“Leadership needs to put steps in place today to improve flexibility, drive resiliency and focus on improved efficiency.”

“Despite economic uncertainty and supply chain challenges, we are seeing a bright future of the automotive tooling industry,” Laurie Harbour, HRI president and CEO, says. “Although we are seeing growth within the industry, it is important to note that NA [North American] tooling spend per vehicle for BEVs on average are lower than ICE [internal combustion engine] vehicles by about 30%, so although we are seeing the tooling spend and number of tools sourced go up over the next few years the average spend per tool is decreasing. So, it will be important for mold and die companies to focus on improved efficiency and throughput.”

HRI predicts that automakers will continue to be faced with difficult strategic decisions about where to put their money and what vehicles to launch. And, that vehicle launch timing will adjust and new vehicles will be planned.

“Although our forecast is positive, there are a number of risk factors that could negatively impact tooling spend, including a prolonged recession, increased supply chain issues or a drop in vehicle demand below 13 million units,” Harbour says. “Businesses need to continuously monitor the health of the industry and their customers to better understand how it will impact their bottom lines.”

In HRI’s most recent Manufacturing Pulse Study, conducted in August, 45% of tool shops indicated they were optimistic or very optimistic about the future and predicted ending the year at 83% utilization. The industry’s top concern remains finding talent and the increasing cost of doing business — neither are predicted to improve significantly in the near term.

“As the tooling market grows, it is important that shops position themselves for the future,” Harbour concludes. “Leadership needs to put steps in place today to improve flexibility, drive resiliency and focus on improved efficiency. Regardless of the forecast, now is the time to be smart and establish plans to shore up weaknesses and address the talent issue facing this industry.”

Read Next

In Automotive, Is Additive Manufacturing an Answer for Die Cast Tooling?

The largest high-pressure die cast tool builder in North America is 3D printing die inserts and water jackets for major automakers. It’s a tough sell, but one company is succeeding — and it’s just getting started.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More