Iscar's 60th Anniversary and New IQ Product Lines

ISCAR continues to expand its existing array of products which established many benchmarks in the global metalworking industry. The new ISCAR IQ campaign introduces several new innovative tool families.

ISCAR continues to expand its existing array of products which established many benchmarks in the global metalworking industry. The new ISCAR IQ campaign introduces several new innovative tool families.

The tool families under the new HIGHQLINE campaign assist the user to increase profitability by employing leading-edge engineering solutions. These new ISCAR tools will enable manufacturers to continue to improve their efficiency in metalworking by using modern machining strategies under ISCAR’s new campaign motto “Machining Intelligently”. The new tools focus on increased productivity with smart insert locking mechanisms, which therefore create a more stable machining process. ISCAR has responded to the new market demands resulting from the trend toward high speed machining and mill-turn CNC, with upgrades in both tool and insert geometries, leading to less machine downtime and less labor.

In today’s economy with tight resources, lean operations and challenging demands, manufacturers need more support from their supply partners. ISCAR strives to work closely with customers, not only to develop new technologies that meet emerging needs, but also to maximize the value of investments in modern machinery by increasing equipment utilization and optimizing performance. ISCAR’s new HIGHQLINE tools are well-suited for the new generation of machining centers, enabling high feeds and speeds for highly productive machining operations.

ISCAR’s new HIGHQLINE is their answer to global market requests. ISCAR has always been at the heart of manufacturing and shall continue to be for many decades to come. The new tools are a part of ISCAR’s commitment to the ongoing success of its customers. As manufacturers struggle to meet increasing demands, ISCAR will use the HIGHQLINE campaign to encourage technical education in automation and advanced technologies in all sectors of the metalworking industry by promoting the motto “Machining Intelligently”.

Some of ISCAR’s best ideas have resulted from its R&D engineers working with their field engineers, who are out in the real world and listening to the needs their customers. Creativity in metalworking is a way of life at ISCAR. Among the new ISCAR tooling innovations are brand names such as:

DOVE IQ TURN - An innovative dovetail pocket combined with a lever clamping mechanism providing very firm and rigid insert clamping for heavy turning.

DOVE IQ GRIP - This new line of tools has a unique frontal locking mechanism designed for deep heavy grooving applications and unobstructed chip flow.

DO-GRIP IQ – These double-ended inserts are clamped with a higher force for grooving and parting, resulting in better accuracy and longer insert life.

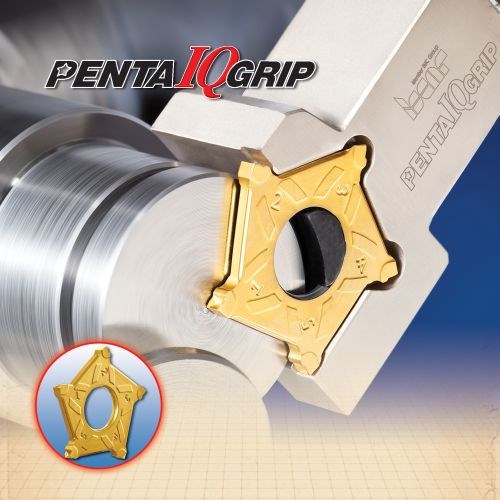

PENTA IQ GRIP – This remarkable design of small pentagonal inserts with 5 cutting edges is intended for deeper and more accurate grooving and parting applications.

HELI IQ MILL 390 – These milling inserts with 3 cutting edges and advanced cutting geometries function with reduced cutting forces and lower power consumption.

DOVE IQ MILL – This milling insert features a unique design with 8 cutting edges for a wide range of face milling applications, including 45o and roughing and finishing operations on a wide range of materials.

HOLD IQ LOCK – This new collet design features strong and reliable clamping , which prevents a tool from being pulled out of the holder in heavy applications.

To enhance customer support, ISCAR continues to develop its unique ITA (ISCAR Tool Advisor), a parametric search engine that raises tool and process selection to an entirely new level. In addition to the online version there are applications available for Apples iOS and Google Android operating systems. ISCAR also has an offline DVD version in 26 languages. ITA has become the industry standard for optimizing tool selection and process parameters. The new HIGHQLINE tools are included in ISCAR’s ITA system.

This is ISCAR’s 60th anniversary year. To continue celebrations, a host of fresh breakthroughs are scheduled for introduction. Leading-edge ISCAR tools will help its customers adapt to high speed machining, minimum quantity lubrication (MQL) and other modern machining strategies. ISCAR’s next 60 years promise to be equally as exciting and eventful with its contributions to modern, efficient metalworking.

Related Content

Certified Quality Management for Plastics Professionals – Materials to Tooling to Recycling

Why is certification of a shop’s quality management system to ISO 9001, AS9100, IATF 16949 or ISO 13485 so special? What does the certification signify? And what supports the paper behind the framed certificate?

Read MoreU.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreDynamic Tool Corp: Leadtime Leader Insights and Bold Plans for the Future | MMT Chats

MoldMaking Technology Editorial Director Christina Fuges gets the scoop from our 2024 Leadtime Leader Award Winner Dynamic Tool Corp., on the company's future, their trade show experience, finding new talent and the impact of this industry recognition.

Read MoreFAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More