Harbour Results Announces Results From COVID-19 Study

Harbour Results, Inc., conducted a study to better understand how the COVID-19 pandemic is impacting small- to medium-sized manufacturers, both production and tooling.

Harbour Results, Inc., (HRI) conducted a study to better understand how the COVID-19 pandemic is impacting small- to medium-sized manufacturers, both production and tooling. The results show that nearly two-thirds of those shops surveyed are operating at some level of reduced capacity or are closed. Additionally, of those shops that are closed, approximately 70% expect to remain closed for more than one month.

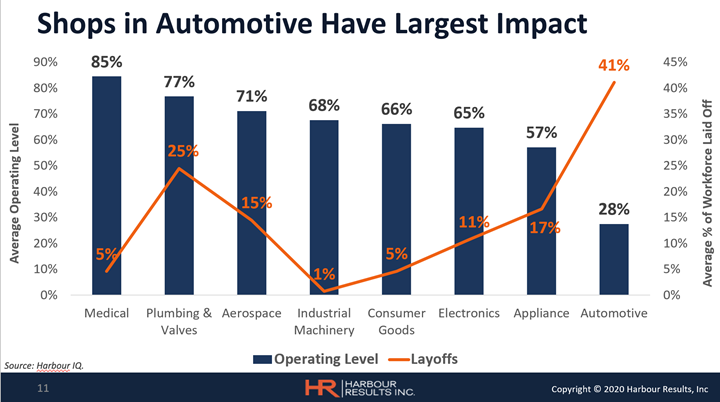

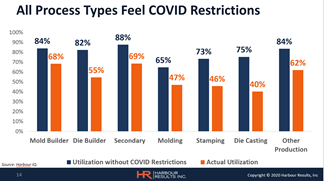

The industries experiencing the highest level of impact are the automotive and home appliance industries. They have the lowest operating levels of 28% and 57% respectively and, on average, those shops in automotive have laid off 41% of its workforce. Additionally, across all manufacturing processes, companies have indicated that utilization has dropped from as little as 18 percentage points to as much as 35 percentage points.

“The manufacturing industry is facing serious headwinds as restrictions on public life remain in effect and will continue for some time. In fact, although some manufacturing is starting to ramp up in May, the marketplace will not return to normal until a COVID-19 vaccine is in place, which could take as long as 18 months,” says Laurie Harbour, president and CEO, Harbour Results, Inc. “The industry has experienced a significant impact, causing ripples throughout the supply chain. And, if a business went into 2020 in a weakened state, it’s really going to show on the backside of this year.”

The study also indicates that shops underestimate the time it will take manufacturers to improve with the majority of respondents stating they will recover in less than two weeks. According to Harbour, “This is overly optimistic. The effects of this crisis have, in some cases, not even shown up for manufacturers and will last through 2020 and into 2021."

During this crisis, operating cash has been a critical component for companies to maintain viability. It this study, nearly half of shops indicated that they had less than six weeks of cash on hand, and 100% are experiencing some level of reduced accounts receivable payments.

“We have not experienced a recession or marketplace like this ever,” added Harbour. “Companies with strong leadership who have reacted quickly to cut costs and manage cash flow will likely have a better chance to survive this crisis.”

Also, as expected, sentiment across manufacturers has dipped drastically with production dropping 21 points to 42% and tooling dipping 9 points to 52%. The top concerns of these shops, in addition to employee health and safety, are a global recession, negative financial implications and sales.

The Harbour Results COVID-19 Impact Study will be conducted on a monthly basis. The results will be analyzed and shared with those companies participating in the study and with industry organizations to help influence the federal government to continue to support the manufacturing industry. The April survey saw more than 320 responses with 55% being tool and die markers and 45% production shops (molders, die casters and stampers).