Conventional Polishing Versus Ultrasonic Polishing

Determining when it is financially smart to consider using an ultrasonic polishing system to reduce finishing time.

Polishing and surface finishing of molds and dies is a very tedious process that requires physical hands-on effort, patience and unique skills that are inherent with a good bench-hand or polisher. There was a time when the entire work process had to be accomplished by hand only; however, over the years, numerous mechanized, air- or electric-operated reciprocating and rotary tools were invented that made work for the polishers easier and faster.

Today conventional polishing is defined by using conventional tools, such as electric motor/flex-shaft driven reciprocating die profilers (filing machines), air-powered profilers and lapping machines as well as various types of rotary handpieces. All of these wonderful machines were designed for large, medium and small surface configurations. As ever-smaller molds and dies were manufactured that required continually deeper, narrower slots and more minute details (for medical or automotive use), conventional tools required additional refinements and improvements.

Ultrasonic Polishing

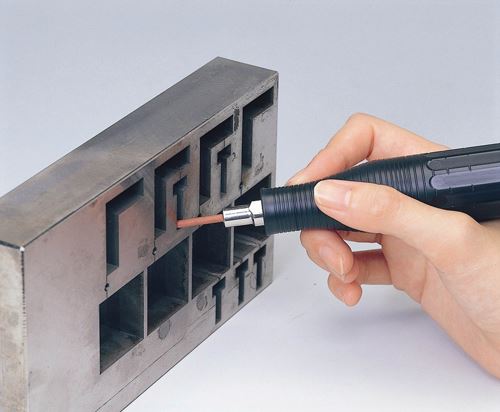

Roughly 35 years ago the first ultrasonic polishing machine made its debut here in the United States. Whereas conventional reciprocating tools are slightly restrictive in movement (caused by the flexible shaft/air hoses, etc.) with an effective stroke length of roughly 1/32 to 1/4" and a comfortable operating speed range of 2500 to 3000 strokes per minute, the tool in a ultrasonic handpiece reciprocates at 21,000 to 25,000 strokes per second and produces a stroke length of only .00004 to .00012 inches. This allows the polisher complete finger tip control when polishing even the most minute details on 40 to 64 RC hard tool steel.

Ultrasonic Finishing

To be fair, ultrasonic polishing is not for everyday normal mold and die polishing; however, ultrasonic finishing has its proper place within the polishing environment. It’s safe to say, when intricate and precise finishing work on hard materials—like heat-treated molds/dies, carbide dies and punches with fine edges and very narrow slots machined by an EDM—is required, it makes smart financial sense to consider using an ultrasonic polishing systems because it can reduce finishing time—with an accomplished polisher—by as much as 40 to 50 percent.

System Specifications

Ultrasonic systems consist of an electronic power module (110 or 220 volt) and a slender, electric cord that powers a very lightweight ultrasonic handpiece. An automatic power feed system adjusts the frequency to accommodate the various abrasive lapping tools that are used for the finishing process. The ultrasonic handpiece comes equipped with numerous clamps that will accommodate tools—from small/fine diamond files to conventional fine grit (hard) stones—as well as ceramic stones and brass laps, which are used in conjunction with diamond compound.

Ultrasonic Systems Power Conventional-Type Polishing Tools

Often ultrasonic systems, in addition to ultrasonic polishing, also power a number of conventional-type polishing tools. Meaning, various models offer dual operating capabilities where the electronic power module not only drives the ultrasonic handpiece, but also regulates the speed and rotational direction for a variety of rotary and/or reciprocating hand tools.

Having these secondary functions presents additional cost savings over single-function ultrasonic units as they permit a full range of filing/reciprocating capabilities as well as rotational grinding/polishing using mounted abrasive points, burrs, polishing brushes and felt bobs. Furthermore, since the rotary or reciprocating hand tools are powered with internal DC motors, the thin electrical cords provide more freedom of movement when compared to flexible shaft-powered tools.

Summary

Several good, but generally very expensive, ultrasonic systems have been available in the marketplace for some time now. However, several recently developed newer models have proven not only to be highly effective ultrasonic polishing systems, but are also very affordable for even the smallest mold shop and/or polishing house.

When selecting a supplier for this type of equipment, it is most prudent to purchase from a respectable company that has been around for many years, provides good customer service, hands-on experience in ultrasonic polishing and offers various systems and accessories that can be readily added as required.

Read Next

Polishing Process: Micro Machining Process

MMP, which stands for micro machining process, is a proprietary superfinishing method for metallic parts that delivers consistent, repeatable results using a finely controlled automated process.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More