.jpg;maxWidth=250;quality=70)

Peggy Malnati MMT, Contributing Writer

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read MoreMicro-Milling Improves Steel Plate Quality, Saving Mold Building Time

Reed City Group switches to steel plate that is flatter, more dimensionally accurate and cuts 10-15% off tool-building time.

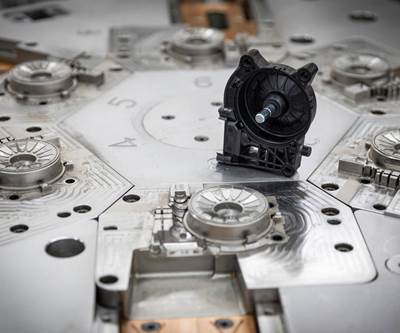

Read MoreThe Lean Dream Team: How to Achieve High-Cavitation, Critical Dimension Molds

Incorporating multiple automation technologies enables Industrial Molds to produce and repair highly complex, precision molds with a very lean team.

Read MoreHow to Extend the Life of Die-Cast Die Components with Proprietary Black Nitride Treatment

Proprietary black nitride treatment significantly increases strength, hardness, wear and soldering resistance of steel die-cast die and mold components.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

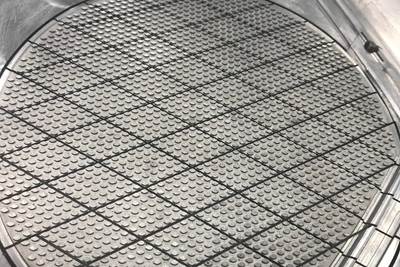

Read MoreHow to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreEase Core-Pulling Installation with Compact Undercut-Relief Device

Patent-pending mechanism simplifies design, machining, installation vs. traditional slides/lifters, eliminates components and uses less space without sacrificing reliability.

WatchHigh-Performance Alloy Increases Performance Capability of Aluminum Molds

DRS Industrial’s use of high-performance aluminum alloys helps it build better molds faster and at a lower cost, improving molder productivity.

Read MoreMichigan Moldmaker Debottlenecks Gundrilling, Increases Efficiency and Profitability

Swapping three gundrills for two CHETO multifunction machining centers, Paragon D&E reduced setups, operating time, increased profitability and shop safety.

Read MoreUsing the Right Technology at the Right Time and in the Right Way

Michigan mold and die maker puts its engineering expertise to work for each customer.

Read MoreMichigan Moldmaker Produces Tools Onshore and Off

Rather than fighting offshore competitors, Liberty Molds has spent the last 15 years producing injection tools in both China and Michigan—and it’s paid off.

Read More