high-tolerance molds and casting dies

Die-Tech is a full-service injection mold and casting die producer. Can you tell us about your company’s engineering-driven approach?

Bill Berry, president: We’re a full-service toolmaker specializing in injection molds and casting dies for the automotive, appliance, furniture, recreational vehicle, motorcycle, consumer products, plumbing, and medical markets. Our molds include actions that many customers and their suppliers don’t even realize are possible. Our dies incorporate features that eliminate many subsequent machining operations. Over the years, we’ve developed design concepts and tooling capabilities that allow us to set our customers apart from their competition. And, yes, we’re very engineering-driven.

We’re an engineering company selling its services in the form of dies and molds.

I started my career as a manufacturing engineer at GM [General Motors Co., Detroit] with a specialty in control systems. I did an overseas assignment to help start up a plant in Spain. At GM, I worked with some of the first CNC machines in industry, which taught me that technology was changing and would upend the tool and die industry. I believed that someone who was properly positioned could take advantage of that and I thought I knew how to do it. My father had been a tool and die maker his whole life and had always dreamed of owning his own shop. As I prepared to leave Spain, we opened a shop in the Grand Rapids area in 1984. I joined him a year later and was the technology advocate at our company. My engineering background made me solve problems differently than guys who’d come up through the trades. When it came time to hire more people, I sought people like me — young engineers fresh out of college. Later, we sponsored a few students at my alma mater GMI [General Motors Institute, now Kettering University, Flint, Michigan]. We now offer a tuition-refund program where we pay the engineering degree of students who work here full-time and keep up their grades. Many of those smart, ambitious engineers are still with us years later. Even if they leave, we benefited from their work during the six or so years it took them to complete their education. That’s why 12 of our nearly 50 employees have advanced engineering degrees. My wife Sandra, our CFO, is an industrial engineer and our two sons, who also work here, are mechanical engineers. Plus, our daughter is a biomedical engineer and medical doctor at St. Jude’s Children’s Hospital [Memphis, Tennessee].

We typically serve smaller manufacturers, not huge corporations. They rely on our engineering expertise to help them present solutions they might not have developed on their own. What we’ve come to understand is if you want to be an engineer, there aren’t many companies willing to pay for engineering. However, if you use your engineering skills to build sophisticated dies and molds containing incredible amount of engineering, then you’ve got a marketable product. So, we’re an engineering company selling its services in the form of dies and molds.

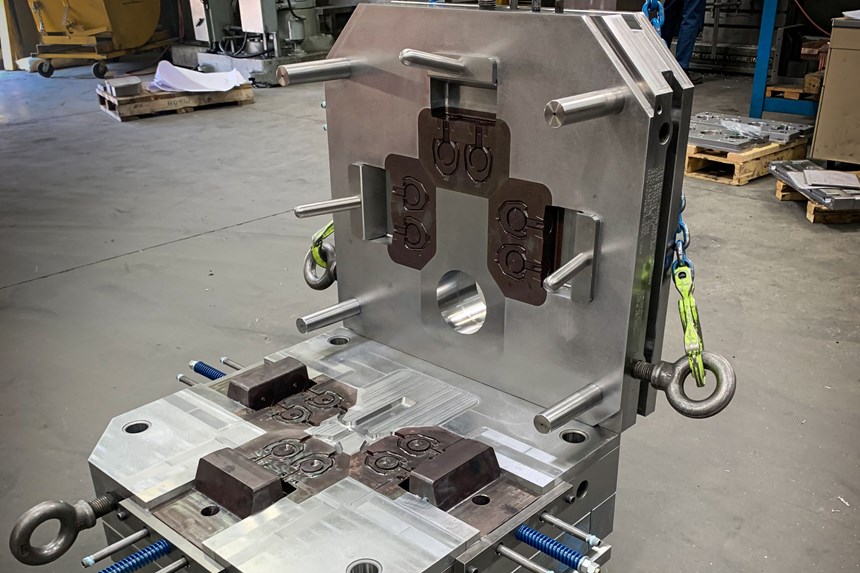

Your company was an early adaptor of Erowa’s standardized work-holding pallets. What attracted you to this technology?

Berry: Having lived in Europe, worked with European machine vendors and regularly attended European tool shows, I was familiar with Erowa [Erowa AG, Büron, Switzerland]. In the 1990s, they introduced their EDM pallets and I immediately recognized how we could use them to streamline our operations. When that technology was introduced here, we were one of the first companies to place a significant order. We design our workpieces with holes that directly mate to the pallet, which mates to the chuck mounted to each EDM, machining center and CMM. Those holes do double duty holding the completed die together. It allows us to move pieces from EDM to three-axis to five-axis machines while ensuring precise positioning. If we need to stop partway through a machining operation to run something else, we can re-secure that workpiece and it will be precisely where it was when we stopped the operation. This ability to precisely control the 3D spatial environment gives us tremendous operational flexibility. It also greatly reduces machine setup because the block is always where it’s meant to be, which is incredibly important on five-axis machines to keep them from crashing. It’s counterintuitive, but it also reduces the need for robotics. To serve machines with robots, someone’s got to attend the robots. If you palletize your work so setup is quick and easy, why invest capital and floor space when humans can do the job quicker and better?

If you palletize your work so setup is quick and easy, why invest capital and floor space when humans can do the job quicker and better?

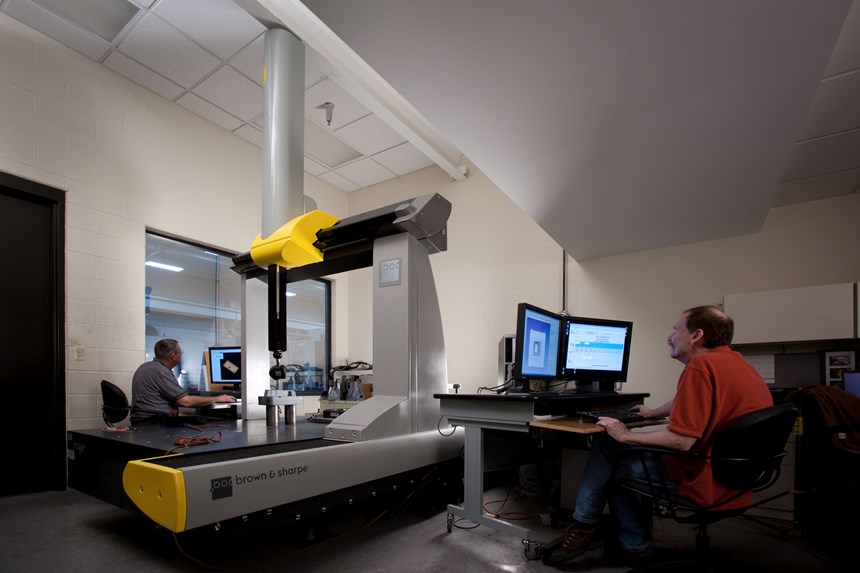

Another technology Die-Tech uses is in-process gauging via laser-scanning CMM. It’s not only used on molds and dies, but also electrodes and core pins. What about this technology do you like?

Berry: We’ve always tried to focus on the appropriate use of advanced technology. For every technology we use, we wait until it’s mature and affordable enough to ensure it’ll reduce costs and increase production speeds, and we use it to its fullest. For example, we held off buying a traditional CMM system, but when laser-scanning CMM arrived, we bought it because we knew it would reduce our tooling costs. It’s the same with five-axis technology. Many people asked me, “How can you afford to buy it when a three-axis machine is $250,000 and a five-axis one is $800,000?” If you use a machine to its fullest extent, you can’t afford not to make the investment. Instead of moving a workpiece around to three different machines, I can do everything on one five-axis machine with one quick setup, faster, better and cheaper.

The way we use our laser CMM is we’ll place an electrode on the chuck for our sinker EDM and scan it using the same work instructions we’ll use to run the EDM. Then we’ll compare it to the virtual model of the mold we’re building. We not only validate that the electrode was cut right and is in the right position, ready to use, but by comparing it to the mold, we’ve also validated the EDM instructions for our operator. This increases confidence that it’s going to EDM the mold right the first time, permitting unattended machining.

Die-Tech has been of great service during this pandemic. What did you do and what does it say about American manufacturing?

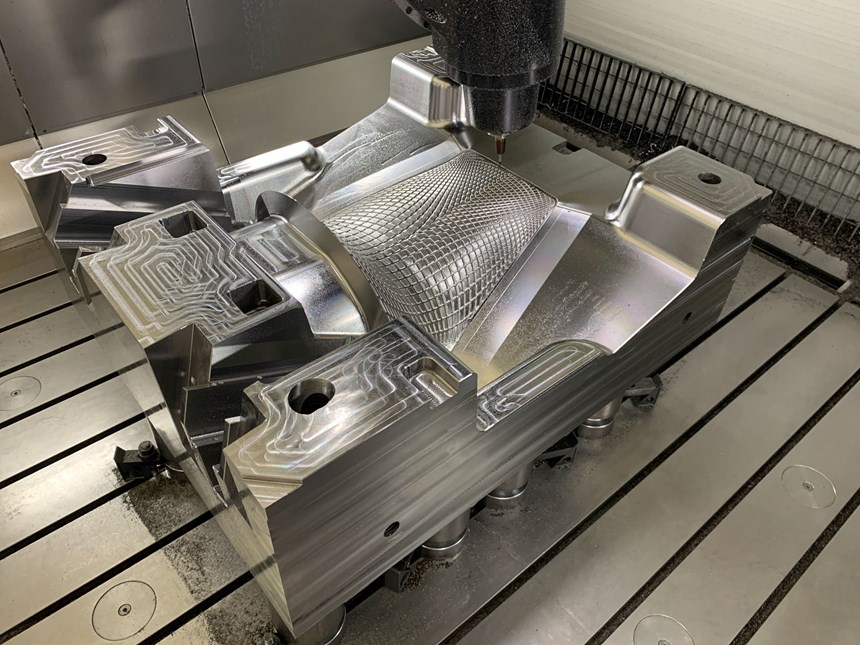

Berry: Around 5:15 p.m. on Friday, March 20th, we received an email asking how quickly we could make some tooling for Ventec ventilators [from Ventec Life Systems, Bothell, Washington]. One tool was a two-cavity die for a piston. I called my contact at Twin Cities [Twin Cities Die Castings Co., Minneapolis] right away and it rapidly became clear the die needed more than two cavities, as the piston was a bottleneck, and Twin Cities needed it very quickly. They were asking for 4-5 weeks’ delivery, which was already shorter than the typical eight-week turnaround. However, we were confident in our process and capabilities so we told them we could deliver a higher cavitation die in one week or less. Twin Cities immediately authorized us to proceed with design and build. I held my engineering team and some of my suppliers over and we did a preliminary design review at 9:00 that evening. We received the initial pieces of steel at 2:00 a.m. from one of our key suppliers, BICO Steel [BICO Steel Service Center, a subsidiary of Burger Iron Co.] here in Grand Rapids. One of my lead engineers worked 23 hours straight. By 5:00 a.m. Sunday, all the steel was in heat treat, and by Monday at 5:00 a.m., we counted 11 of our five-axis machines working on components. We shipped the die Wednesday at 2:00 p.m.. Because we built and delivered a high-quality production die in four-and-a-half days, they gave us seven more dies to build for other ventilator components.

With current technology, I don’t think you could physically build dies faster than we did on this project. We could do it because our own team and our suppliers were incredible, and because our systems are so refined that there are no wasted steps. We do everything at once on high-performance machines that run very fast. Also, with pandemic work slowdowns, we could clear all of our machines to focus solely on this job, which was made easier because of our pallets.

This project was an incredible opportunity for us. More importantly, it was a testament to what American manufacturing can do and how imperative it is to keep strong manufacturing in this country—not only for our security, but to ensure the quality of life and great jobs our parents enjoyed. High-volume production can’t happen without tooling. The fact that so much of our tooling supply base has been outsourced to foreign countries prevents this kind of response unless you still have strong domestic suppliers. Tooling is to manufacturing what seeds are to farmers. You’d be foolish to outsource all your seed production.

I’ve had major customers tell me their management said they weren’t doing their job right if they weren’t buying molds from China. That’s so short-sighted, especially given the small percentage tooling represents in the total cost of producing something. We recently saved a major customer more than the cost of tooling on a project and they still took next-generation tooling off-shore. Perhaps we need legislation to keep tooling here. It’s the basis for manufacturing and we shouldn’t give it up. I feel our moldmaking industry made big mistakes years ago. We should’ve insisted that our tool designs were licensed to users to support the tools we built, and not something customers could copy and take to another country to be rebuilt by someone else. I passionately believe that’s got to change.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

Mission Complete: Die-Tech Update on Ventilator Tooling to Combat COVID-19

Die-Tech & Engineering President Bill Berry shares an internal letter to update his team on where things stand with their ventilator tooling projects and express his gratitude for all of their hard work.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;width=70;height=70;mode=crop)