MMT Blog

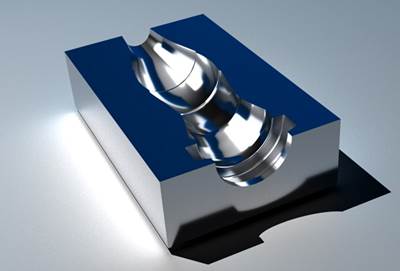

Improve Mold Machining With Equidistant Offset, Rest Finishing and Innovative Five-Axis Toolpath Strategies

The right CAD/CAM software helps mold builders better manage complex tool paths, improve the effectiveness of CNC finishing tool paths and take advantage of innovative five-axis machining toolpath strategies.

Read MoreEditorial Advisory Board 2023-2026: Meet New Board Member Corey Bratton, Quality Mold

The 2023-2026 version of MoldMaking Technology's EAB features a new crew of industry professionals. Here's one of them.

Read MoreHow to Create Custom Grants for Your Moldmaking Business

Don’t just respond to grant solicitations; create ones that meet your mold shop's needs.

Read MoreMMT Chats: Looking to Reinvent the SPE Mold Technologies Division

SPE Mold Technologies Division Chair breaks down all of the society’s current initiatives. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchTo the Next Level: Hot Runners, Mold Components Solutions and Services

Moldmaking can be a complex business, but things can be simplified with the right hot runner and mold component technologies and services.

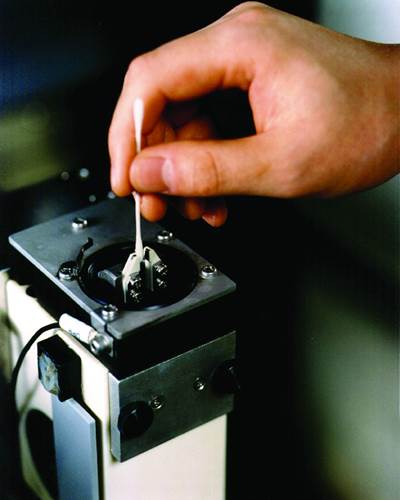

WatchMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

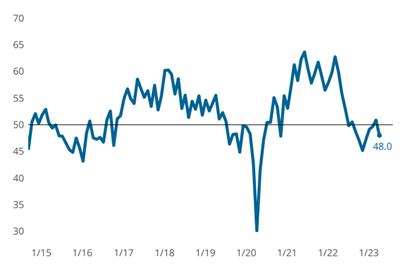

Read MoreMoldmaking GBI Returns to Contraction After One-Month Respite

After a challenging move into the 50s in March, the April GBI returned to a mostly consistent state of contraction, the result of recent market dynamics.

Read MoreVIDEO: Hot Runners and Sustainability

Oerlikon HRSflow North America Sales Director Robert Harvey breaks down hot runner technology that addresses sustainability opportunities and challenges.

WatchWhat is the Moldmaking Community Excited About?

As we continue to celebrate MoldMaking Technology’s 25th anniversary with a look back over the past quarter century, I asked readers during our recent Plastics Technology Expo (PTXPO) “What excites you about the future of moldmaking?”

Read MoreMMT Chats: SPE MTD 2023 Mold Repair Person of the Year

MoldMaking Technology Editorial Director Christina Fuges sits down with the newly named SPE Mold Technologies Division 2023 Mold Repair Person of the Year to learn about his passion for mold repair. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchStability, High Speed, Flexibility of Five-Axis Portal Milling Machine Reduces Rework for Mold Builder

The thermo-symmetrical construction of a five-axis portal milling machine with a center-guided Z-axis enables higher accuracy, reducing rework. Also, the symmetrical design and the guide arrangement increase stability and save weight, making the machine more dynamic, productive and energy-efficient.

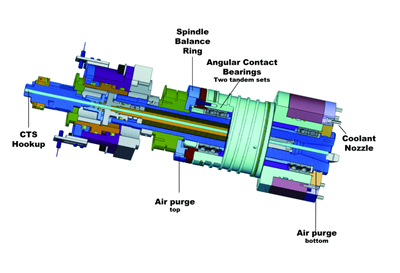

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read More

.jpg;maxWidth=300;quality=90)