MMT Blog

Technology and Sourcing Guide 2023: Hot Runners

Hot runners deliver the material into the mold to make the part. These systems consist of hot halves, nozzles, gates and temperature controllers — all of which must be monitored, maintained and cleaned to guarantee a quality end product.

Read MoreMMT Chats: 5 in 5 with StackTeck

MoldMaking Technology Editorial Director Christina Fuges gets leading mold builders to reveal 5 best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive ... in 5 minutes. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchTechnology and Sourcing Guide 2023: Mold Builders

A variety of processes are used to engineer, build, maintain, repair and manage a mold, which can be offered as standalone services to be contracted to complete a mold build. Access this exclusive, online-only content, including a suppliers list and mold building services.

Read MoreTechnology and Sourcing Guide 2023: Mold Materials

Proper selection of the appropriate mold material is critical to manufacturing a high-quality mold. Tool steel, aluminum, copper and alloys are some of the materials used.

Read MoreEditorial Advisory Board 2023-2026: Meet New Board Member Jenny Kotulak, Integrity Tool and Mold

The 2023-2026 version of MoldMaking Technology’s EAB features a new crew of industry professionals. Meet Jenny Kotulak.

Read MoreVIDEO: How to Protect Your Hot Runner Systems

Chad Root Managing Partner for Fast Heat by Spark Industries reviews some molding machine integration concepts that protect hot runner systems, the molding machine, reduce scrap and help keep a log of events.

WatchMoldMaking Conference Session Spotlight: Mold Design

Want to learn about collaborative mold design or a plan to reduce back-end troubleshooting?

Read MoreTechnology and Sourcing Guide 2023: Cutting Tools

Cutting tools are used on machine tools to cut metal, and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish.

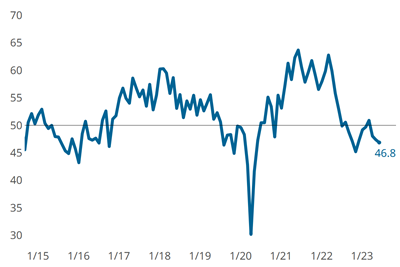

Read MoreJune GBI: Moldmaking — More of the Same

Several components contracted even faster in June, driving a consecutive second 0.6-point drop in moldmaking activity.

Read MoreTurning the Tables on Me ... Conversation All About Moldmaking

Being a guest on the All-Axis Podcast by Tebis was a pleasure to talk about all things moldmaking.

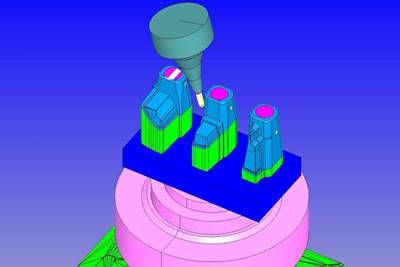

Read MoreTechnology and Sourcing Guide 2023: Software

Design and engineering are essential to building a better and more cost-effective mold with shorter lead times. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming.

Read MoreQ&A: How to Optimize Micro Molding Outcomes

Molding at the micro-scale requires a completely new perspective concerning rheology, tooling, gating, handling and assembly. Accumold Sales Engineer Craig Tappe explains the micro molding process and the right questions to ask when securing a tooling specialist.

Read More

.jpg;maxWidth=300;quality=90)