MMT Blog

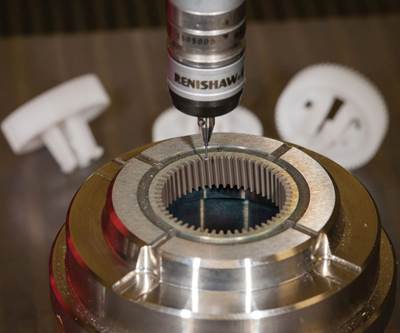

Apprentice Training - Precision Inspection and Measurement

Here are some basic principles concerning inspection and measurement to take into account when developing your related technical instruction (RTI) plan.

Read MoreLeadtime Leader Q&A: Inspection and Measurement

Moldmaking Technology's 2016 Leadtime Leaders share their views on inspection and measurement.

Read MoreAutomotive and Packaging

Automotive spending surges, and rapidly growing food/beverage spending also means more packaging.

Read MoreAn Added Layer of EDM Knowledge

Understanding electrode material selection and the relationship among the electrode, workpiece material and machine parameters can improve EDM efficiency.

Read MoreInt'l Perspective: Think Global, Act Local, and Cooperate

The new generation of company owners and managers count on cooperation with other mold shops or even competitors in order to remain globally competitive, and the moldmaking business is an increasingly global one.

Read MoreMonitor Your Machines

If you manage or work on a shop floor, then you have likely heard about machine monitoring.

Read MoreDefining Mold Steel Toughness

Consider grades that have undergone the electroslag remelting process.

Read More2017 Editorial Advisory Board: Tim Krieger

The 2017 version of MoldMaking Technology's EAB features a new crew of 10 industry professionals. Here's one of them.

Read MoreSharpening Their Edge

Continued facility and equipment investment helps to maintain a focus on consistency in cutting tool design and manufacture for Seco Tools and Niagara Cutter. This includes two products developed to utilize the entire capability of the machine tools on the market today.

Read MoreThrowback Thursday: Run Clean, Run Efficient

If you or your customer is concerned with achieving faster cycle times (and who isn't?) plus cleanroom-caliber mold function and lower maintenance, here's a throwback case study about better undercut release for small medical, or similar, parts using expandable cavities.

Read MoreStudy Shows Advantages of Mold Heating and Cooling Technologies

RocTool, a developer of mold heating and cooling technologies, shares the findings of a study it conducted to identify a range of resin materials that successfully use RocTool’s molding technologies to produce high-quality parts with high flow and reduced cavity pressure.

Read More