MMT Blog

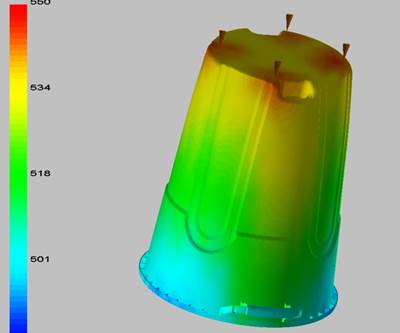

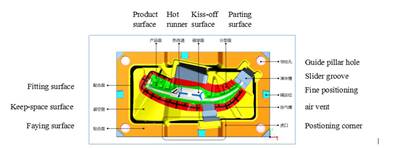

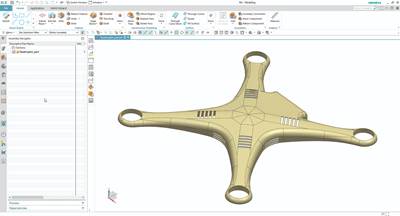

How to Design High-Efficiency Capabilities into an Injection Mold/Molding System

Mold builders can boost profits and part quality with expert analysis and optimization techniques.

Read MoreWhat Can 3D Printing Really Do?

And what will it mean for the future of manufacturing? “The Cool Parts Show,” a new video series from Additive Manufacturing, answers these questions with real examples. Watch the first season now.

Read MoreNoteworthy News: Gratifying Get-Togethers

These industry events from DMG MORI, Haimer USA and Mazak Corporation provide exciting insights to latest technologies, as well as chances to meet and greet with friends both old and new.

Read MoreOn-Machine In-Process Inspection Improves Machining Accuracy

High-speed machining with on-machine in-process inspection, machining management, and control technology reduces machining time and eliminates manual bench work.

Read MoreHow to Pre-Estimate Tooling Costs

The right costing software can help to improve mold quoting and production.

Read MoreTech Trends: Suitable Software

CAM software programs and updates from Autodesk, Inc., CAM-TOOL by CGS North America, Inc., and CGTech provide a range of features, including independent operation, reduced cycle times and easier machining programming, simulation and verification.

Read MoreWhen It Comes to Shop Safety, Think Beyond Pallets and Blocks

More often than not when touring a shop I see a unique approach to solving an everyday problem. This time it was a shop full of big, heavy molds that were not sitting on pallets or blocks across the the floor. Instead, they were sitting on top of small, plastic feet.

Watch5 Reasons to Consider Automation

As ongoing advances enable machines and humans to get better at talking to each other, eventually more shops will become more automated. If your shop hasn’t yet looked into upping its automation game, here are five reasons why you should.

Read MoreIf A Mold Could Talk ... What Would It Say?

The MMT “Top 10 Reasons to Be a Moldmaker” t-shirt has become very popular over the years as a way for moldmaking professionals to share their humor, but recently I discovered another way for you to unleash your wit and wisdom: introducing the “Life of a Mold” campaign! And, we need your help.

Read MoreNoteworthy News: Teaming Up

Catch up on the latest business partnerships within the moldmaking community from Hurco Companies, Inc., iD Additives, Inc., PCS Company, RJG and HRSflow.

Read MorePODCAST: What Do Rhinos Have to Do with Repair?

United Tool and Mold Owner Scott Phipps recalls “always building something" as a kid, and that continues today as he and his team charge forward with expanding and improving their mold repair and engineering change services business. Who are they and how are they growing this critical segment of mold manufacturing? Listen in to learn.

ListenVIDEO: The Importance of Facility and Flow to Mold Repair and Engineering Changes

United Tool and Mold Owner Scott Phipps speaks with MoldMaking Technology Editorial Director Christina Fuges about its new 60,000-square-foot facility dedicated to large mold repair and engineering changes, which has improved the company's competitiveness and their future plans for growth and improvement.

Watch