When It Comes to Shop Safety, Think Beyond Pallets and Blocks

More often than not when touring a shop I see a unique approach to solving an everyday problem. This time it was a shop full of big, heavy molds that were not sitting on pallets or blocks across the the floor. Instead, they were sitting on top of small, plastic feet.

I found out that these feet are actually magnetic support pads that are designed to keep materials elevated off of surfaces and they travel with the workpiece. The concept came from decades of scientific research on how a rhinoceros can support its massive body weight with relatively small feet. Scientists discovered that it’s all about how their feet distribute weight. Hence, Rhino Feet™ elevation pads were born and designed with the same theory.

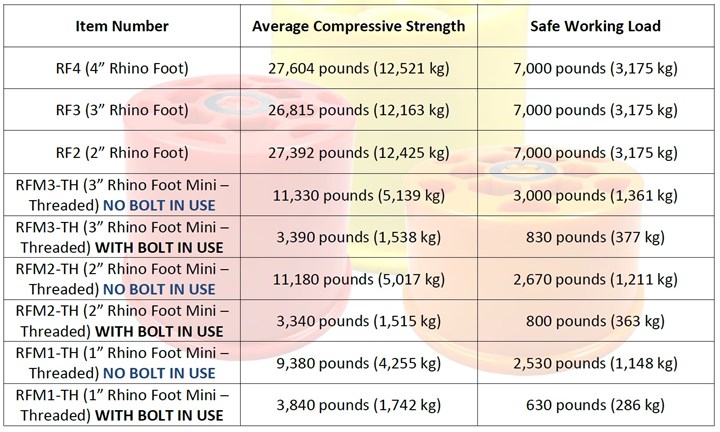

When used properly, Rhino Feet can support extremely heavy objects, which makes them perfect for mold shops. These pads have undergone rigorous destructive testing to ensure the product is safe to use in industrial settings. Multiple tests have been performed on each size Rhino Foot to determine the average compressive yield strength and safe working loads.

Related Content

-

MoldMaking Conference Session Spotlight: Data

Want to learn about digital workflows in mold design or ERP or global mold monitoring and asset management or the impact of tooling digitalization?

-

FAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

-

VIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.