Three Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Mills are starting to respond to pricing demands and are now producing different types of steel to give tool shops a cost advantage.

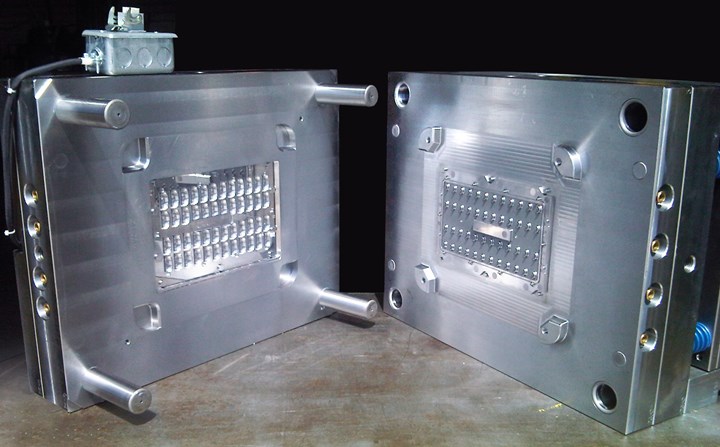

Photo Credit: International Mold Steel Inc.

Tools shops are looking for three things from their steel suppliers — steel that is inexpensive, good quality and can be delivered fast. The problem is that you rarely get all three of these needs filled at the same time. So, what is the most important of the three?

1. Quality

Quality is always at the top of the list. The last thing a tool shop needs is to have a steel problem while the mold is in production. Returning a mold for repair is not good for all parties involved. Repair costs in addition to production downtime are extremely costly.

Today’s mills are committed to quality. Some have added high-speed forging presses to their process. These new presses have shown to improve the matrix of the steels that they offer to the market. An improved matrix means less chemical segregation as well as improved hardenability and less stress in the steel. These factors will help determine future costs down the road for tool shops and their customers.

With that being said, there is steel coming in from third-world countries that is not up to the high quality standards that tool shops are used to receiving. This reduced quality often leads to higher down-the-road costs in additional labor and subsequent machining for tool shops and their customers.

2. Fast Delivery

One of the ways that North American shops are combating foreign tooling coming into the country is with fast delivery. In order for tool shops to offer quick turnaround, they are asking their steel suppliers to do more. Some steel suppliers are supplying their products squared to tight tolerances. This gives tool shops the ability to put the steel into their CNC machines and start on the cavity and core cutting right away. Other steel suppliers are also offering gun drilling as a method for cutting down on delivery times.

In the past year, the oil and gas industry has purchased large amounts of capacity from some of the mills, resulting in long lead times — in some cases, 28-32 weeks. This trend is leaving tools shops without a quality steel source for their molds. Some steel suppliers around the country are stocking larger blocks on their floor as way to maintain a viable source of material for these shops.

3. Price

We have all heard the phrase, “Cheaper never means better.” Everyone wants the best price they can get for their steel, and the mills have taken notice and are starting to respond to these pricing demands. Mills are now producing different types of steel to give tool shops a cost advantage.

In the U.S., tool shops and molders have settled on double-melted P20 for automotive lens applications. However, there are now several grades of single-melted P20 lens quality accepted in Europe. These single melt steels are producing quality parts at a lower cost.

Another way to reduce tooling costs is to evaluate pre-hardened steels versus heat treatable steels. Eliminating the need for heat treating can greatly reduce the amount of time spent on heat treating along with secondary machining for these heat treatable steels.

New pre-hardened steels also offer tools shops a material in the mid 40 HRC range. These products are competitively priced, compared with regular H-13 types, but eliminate the need for the heat treatment. Some preliminary results with regards to longevity have shown little to no parting line wear and no ejector pin wear — even after 2 million shots on the tool.

The industry standard for hardened steels is H-13. It has been used successfully for years. However, newer materials that are pre-hardened, have mid 40 HRC and provide the same life as an H-13 are definitely worth testing.

New high quality stainless steels should also be evaluated. They offer better machinability, increased weldability and lower costs down the road with regards to mold maintenance. Some materials are designed primarily for mold bases due to their chemistry (sulfur) whereas others are made for the medical market due to their corrosion resistance.

Summary

The biggest challenge is selecting the right steel for the right job; however, steel selection has never been better in regards to quality, price and delivery speed. If you haven’t looked lately, now is the time. There is no grade of steel that fits every application, but getting it right the first time is paramount. The easiest and best way to improve your steel selection process is to call your steel supplier. They can usually match the application with a product that will work best.

Related Content

VIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreReliable, Efficient 3D Printer for High-Quality Tool Steel Components

The updated TruPrint 2000 underscores Trumpf’s focus on the tool and die industry, including a larger, square build plate and various features to ensure high quality and mass production.

Read MoreVIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

Tool Steel and Aluminum Staying Strong

A roundtable of mold material suppliers discuss how new offerings result in easier machinability, better weldabilty, increased strength and improved surface hardness.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More