ISO 9000 Model 1 - Quality Issues as a Part of Good Business

Solutions for managing the plastics supply chain improving OEMs' total cost of manufacturing.

A tool to enhance improvement implementation and deployment. ISO 9000 year 2000 - generating an efficient quality cycle requires getting people at all levels of the organization connected and committed to improvement and encouraging their participation in improvement activities through proactive management leadership. Customer focused.

This article describes solutions for managing the plastics supply chain - improving OEMs' total cost of manufacturing. Subjects include outsourcing and contract manufacturing to reputable, qualified, industry-specific, ISO 9000-certified companies.

The Plastics ISO 9000 Model includes:

- Tooling & Equipment-Specific with Performance Measures

- Process-Specific with Performance Measures

- Materials-Specific with Performance Measures

- Services-Specific with Performance Measures

A company begins benchmarking by taking its own current performance measurements, production efficiencies, scrap rate, machine utilization and so forth. Doing so provides benchmarks that can be used to compare one company to another. The analysis phase involves determining current performance levels.

The action phase requires developing a plan for implementing findings, then implementing actions and monitoring progress. Benchmarks should be recalibrated as necessary to reflect progress and necessary improvements.

This article promotes standard operating procedures and checklists for quality conscience individuals to follow, satisfying the global supply chain:

- Capitalizing on supply chain competency.

- Finding the hidden value in your supply chain.

- Elements of successful supply chain planning.

- How much does your supply chain cost?

Here is a checklist to bring your documentation up-to-date for ISO 9000:2000 compliance. Does your documentation contain:

- Housekeeping ... Report Card?

- Tooling & Equipment ... Performance Report Card?

- Machinery ... Calibration Records?

- Materials Purchases ... Performance Report Card?

- Processes Instructions/Control Charts?

- Subassemblies Controls?

- Part Quality Measures?

- Customers' Satisfaction Measures?

- Total Cost of Ownership Measures?

- Sales Performance Measures?

- Training Program Schedule?

- Common plastics industry requirements, list standards and practices for product and plant safety, environmental and health-related issues (i.e. UL, USP, OSHA, ANSI, etc.).

- Self Internal Audit Reports monitoring and measuring the above for corrective actions.

What is a measure? Answer - acceptable quality levels. Most of us have heard of the six sigma black belt scheme. Well, since the beginning, processors have been in business implementing procedures to improve on acceptable quality levels - you know, those AQLs required by your customers. Six sigma is a statistical number representing the acceptable/unacceptable level of each company-wide process (order entry, invoicing, manufacturing, product, customer satisfaction, suppliers' performance, employee accident rate, etc.).

Here is a table to gauge each process in your organization:

| Sigma | Individual Company-Wide Process |

| 6 | 3 defects per million (world-class) |

| 5 | 233 defects per million |

| 4 | 6,000 defects per million (industry average) |

| 3 | 66,000 defects per million |

| 2 | 308,000 defects per million (noncompetitive) |

Following is some practical information on quality solutions for managing the plastics supply chain. Know your clients' markets and customers. Help your clients' engineers and buyers when they are outsourcing manufacturing, design and total cost of ownership vs. individual part/component price. Be your clients' plastics professional partner serving the supply chain - tooling, process, materials and servicing.

History

ISO 9000 started in 1987; was revised in 1994 and now again in the year 2000. Confused? Well, with 20+ years in highly visible positions in operations/plant management/fabrication experience bringing solutions for managing the plastics supply chain and helping the customer solve problems is a priority; I conducted an in-depth investigation and realism on the ISO 9000 standard and this paper will help answer the questions arising everyday on business improvement and performance; requirements mandated by both the standard and your customers. Study it carefully and use it as a tool to improve your internal and external operations.

Six Major Changes

1) Once ISO 9001:2000 is published, ISO 9002 and ISO 9003 will be withdrawn, because the newest revision will continue to provide users the flexibility of the three standards, but in one document. ISO 9001 will now be concerned about documented business processes:

- Management responsibility.

- Resource management.

- Process management (six sigma target performance).

- Improvements through measurements and analysis.

- Total customer satisfaction. ISO 9001:2000 Goals

- Continuous improvement and cost reductions.

- Emphasis on defect prevention.

- Reduction of variations and waste in the supply chain.

- One standard for all markets and suppliers quality system requirements.

2) Common Industry-Sector Requirements. Standards and practices for product and plant safety, environmental and health-related issues.

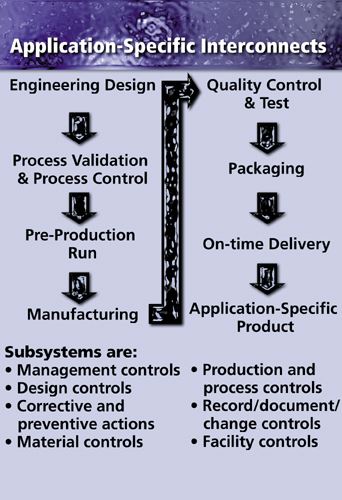

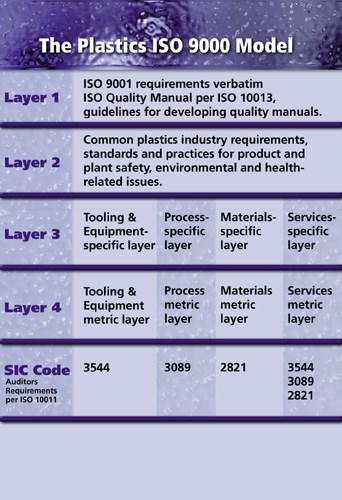

3) ISO 9001:2000 calls for industry-specific professionals - trainers and auditors. Enforcing/mandating ISO 10011 requirements for auditors to audit specific-industry SIC (Standard Industrial Classification) Codes overlooked in the past. The Plastics ISO 9000 Model (see Figure 1) represents the plastics industry solution for managing the plastics supply chain to ISO 9001:2000. The flow of product manufacturing is illustrated in Application-Specific Interconnects (see Figure 2). Here the required subsystems controls are recorded.

The ISO 9000 for Plastics Structure Uses a Four-Layer Model

- Layer 1 contains the requirement clauses of ISO 9001 verbatim.

- Layer 2 contains common plastics industry requirements that apply to tooling & equipment, process, materials and services.

- Layer 3 contains those requirements that are specific to tooling & equipment, process, materials and services.

- Layer 4 provides metrics - the measurement tools to be used with tooling & equipment, process, materials and services - to be used to measure results relative to the requirements.

4) Additional industry-specific accreditation requirements for registrars to follow and the accreditation is recognized in all countries.

5) ISO 9001:2000 emphasizes the requirements of suppliers by key market end users:

Automotive, Electrical/Electronics, Computers/Business Machines, Telecommunications, Packaging, Beverage, Containers/ Closures, Food Services, Building/Construction, Plumbing, Appliances, Consumer Products, Recreation/Sporting Goods, Lawn & Garden, Agriculture, Medical/Pharmaceutical, Industrial, Office Products, Furniture, Government/Defense and Aerospace.

6) Third-party registration vs. self-declaration compliance.

International Committee on Standards and Conformity Assessment (ICSCA), 58-plus American and European multinationals are calling for self-declaration to ISO 9001 in the year 2005 and a halt to attached third-party registration schemes.

Partial Members List:

Alcatel, AMP, Becton-Dickinson, Bell Labs, Boeing, Daimler Benz, DEC, Ericsson, Ford Motor, GM, Hewlett-Packard, IBM, Lucent, Motorola, Philips, Rockwell, Siemens, Texas Instruments, United Technologies, Volvo and Xerox. Along with industry associations, i.e. National Association of Manufacturers (NAM, U.S.), Association of the German Industry (Bundesverband der Deutschen Industries). Source: ASQ; Quality Progress, August 1998.

Assessment Requirements

The process flow of company-wide assessment is illustrated in Figure 3 and designed to help you prepare for audit documentation required by ISO 9001:2000.

Business Outlook

For plastics manufacturers to succeed and grow their business in this millennium, they will have to find ways to reduce the cost of product lines (acquisition) for customers, through value-added services. We used to talk to customers about the price of a part or a series of parts. Today, we talk about the total cost of acquisition. We now talk about cycle time and the ability to forecast versus the changing lead-times of our suppliers. ISO 9001:2000 requires improvements and measures on these topics.

Plastics leaders with Internet and e-commerce technology use information technology and high-tech tools to differentiate themselves from competitors. They provide customers with a range of Internet services including online ordering, interactive training sessions, product seminars, the ability to download technical data sheets, and 24 hour-per-day, seven-day-per-week access to real-time customer support. ISO 9001:2000 requires validation for accuracy on the software being employed.

ISO 9000 revision 2000 allows companies, their suppliers and customers to connect with each other to lower costs and improve productivity. All of their locations are linked by computer systems to deliver supply chain services to customers. ISO created an enterprise solution for customers to link their supply chain around the world to coordinate engineering, bill of materials management, forecasting, and materials handling all together - similar to a global enterprise resource planning (ERP) solution. The system [ISO 9000:2000 standard] calls for other tools, including material requirements planning (MRP), electronic data interchange (EDI), and distribution resource planning (DRP) for tracking and managing forecasts and warehousing. These types of value-added solutions are becoming more important as more OEMs outsource production to contract manufacturers.

Outsourcing ISO 9001:2000

For more than a decade, executives across corporate America have used outsourcing to become more efficient and to better focus on internal resources. Corporations are reducing their supply base, outsourcing manufacturing in an effort to base its buying decisions on the measured total cost of ownership (TCO). As a result, they have concluded, a quality management system combines practical experience with industry-specific leading edge thinking. They realize ISO 9001:2000 not only explores quality improvements' most recent development, but helps shape the field on quality for years to come.

Outsourcing impacts both the customer and the supply chain. Executives are now focusing on their clients and their clients' customers - the entire value chain. ISO 9001:2000 considers the supply-chain contributor as an extension of the individual client's factory. Senior managers surveyed cited vendor/supplier quality as a primary obstacle to profitability. Vendors/suppliers are aware of but not committed to the need for total quality. Business professionals find the need for a practical quality standard.

ISO 9001:2000 promises "what to do" and "how to do it." ISO 9000 is shaping the world economy and companies must be aware of how it relates to them and their customer base. As companies must choose their markets and decide how they will reach those markets at a reasonable cost, the cost of instituting an ISO 9000 program can be a major factor. So far, the costs surrounding ISO 9000 certification have been quite high. Base price is reported at $35,000; mid-sized companies may pay up to $250,000 and large companies can see costs hit the $1 million mark. Please keep in mind that these costs may be fine for large OEMs, first-tier and second-tier suppliers generating hundreds of millions to billions of dollars in annual revenues. Small companies - fewer than 500 employees - in the plastics industry supply-chain, need not pay more than $25,000 for training, implementation and certification - with guarantees of improved internal operations and an increase in their customer base.

Outsourcing ISO 9001:2000 requires operations/plant management/fabrication experience. Helping the customer solve problems is a priority. ISO 9001:2000 is a road map to this task. The outside contractor shall also provide and assist in areas of quality systems, management and business, manufacturing operations and workforce development/motivation. After all, you need guarantees to your bottom line just like your customers are requiring from you for their bottom line.

Benefits/Value Added by an ISO 9000 Certificate

ISO 9001:2000 provides training in linkage of processes, team building, statistical methods for process control and failure analysis. The standard measures the facility for excellence, including how the quality, safety and environmental functions affect the facility's bottom line, both directly and indirectly through self-auditing. Supplier-Company-Customer.

Accomplishments include product marketing and project management development. Audits of organizations for effectiveness, performance and development of quality supplier/customer goals and strategies. Direct the strategic quality planning process that is oriented to bottom-line results, customer relations and operational excellence. Improved market share and a higher return on equity. Policy, procedures and a quality manual attest to this with measurable results. Innovative and proven methods of using customer information for profitable management decisions (strategic planning, outsourcing, cost/productivity, purchasing, FDA, USP, OSHA requirements and customers' internal and external expectations) are included. Thus, the ISO 9001:2000 standard combines real-world business experience with a strong background in total quality management (TQM).

- Team building and employee motivation is the basis for the ISO 9001:2000 standard.

- All end markets are served through one quality assurance management standard.

- Implement solutions in defining and updating departmental business measures to six sigma performance:

1) Financial measures (ROI).

2) Quality measures (scrap, rework, and returns).

3) Customer measures (customer feedback).

4) Productivity measures (yields trends).

5) Workforce measures (team building/employee & manage-ment motivation).

6) Market measures (increased customer base, customer satisfaction, and customer perception).

7) Vendor measures (supplier scorecard).

8) Safety measures (employee & management training).

9) Environmental measures (awareness program).

Conclusion

ISO 9000 is experiencing change to operate plants productively and safely with a skilled and motivated workforce. ISO 9001:2000 consistent quality is attested by ISO 9001 certification (third-party registration and/or self-declaration compliance), which applies not only to proven quality in production, but also in design/development and sales/customer satisfaction. OEMs and end-users are looking for a combination of expertise, responsiveness and personal commitment that ensures the best possible product-line solution from their suppliers. Outsourcing is their strategic and difficult decision - choosing partners to address technology, manufacturing quality, dependability/delivery, responsiveness and value.

ISO 9001:2000/Industry Partnerships are moving toward more equitable, quality solutions. Reversing what was often an adversarial relationship, ISO has worked with industry representatives to implement changes designed to improve the agency's inspection and enforcement policies. Owners and stakeholders responsible for running a business do not only follow good quality practices because of standards; they know good quality is just good business.

Abbreviations

ISO (International Organization for Standardization)

OEM (Original Equipment Manufacturer)

UL (Underwriters Laboratory)

USP (United States Pharmacopoeia)

OSHA (Occupational Safety and Health Administration)

ANSI (American National Standards Institute)

SIC Code (Standard Industrial Classification)

FDA (Food and Drug Administration)

ROI (Return on Investment)

Related Content

MMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More