The Graphite Grade Factor

Understanding how graphite is made will help you select the proper grade.

Moldmaking in the present day has seen many technological advances throughout the realm of EDM. We have seen significant upgrades in sinker machines that compensate for potential deficiencies in running conditions. The implementation of automation is commonplace to combat rising labor costs. Quick change tooling aids in rapid turn-around. One thing operators rarely consider as an area of technological significance is the graphite consumables they use.

Graphite Manufacture

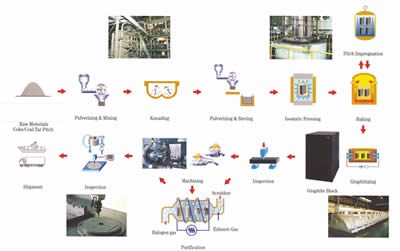

Graphite takes roughly six months to manufacture from beginning to end. During this process a meticulous observation of quality needs to take place throughout every step of production. This begins in the selection of raw materials. Different sources for coal tar pitch and coke materials result in different final properties for the graphite that is produced.

These raw materials are crushed and sieved numerous times to ensure the con-sistency of the resultant particles. The mix-ing then occurs to ensure the particle distribution is correct. This mixture is placed in rubber sleeves and put into an isostatic press. Isostatic means constant pressure. This piece of equipment is crucial to ensure the properties in the block are isotropic. Iso-tropic generally means that the graphite will have homogeneous or similar properties throughout the block and consistent quality.

After the blocks are removed from the press they are still in the green stage—meaning they need to be transformed through heat treatment from carbon to graphite. Each graphite grade has a particular heat treat recipe that aids in the final formulation and will help determine the properties it will possess.

Graphite is baked at a very slow rate to ensure the gases within the blocks are not released too rapidly. That would cause an increased rate of cracked blocks. Some grades can be re-impregnated with pitch at pressure to ensure higher densities and baked a second time. The last step is a high temperature graphitization process that will complete the transformation from carbon to graphite by adjusting the crystalline structure of the material.

It is imperative that during every step along the manufacturing process quality checks are performed to ensure the graphite blocks meet quality standards. It also is important that the graphite manufacturer works to improve the performance of the graphite it makes. Employing a large staff of engineers who constantly develop grades for the ever-changing EDM marketplace is essential.

Choosing the Correct Grade

Now that we know generally how graphite is made, how do we choose the correct grade? In order to maintain cost effectiveness, an EDM shop needs to choose EDM graphite that provides dependable quality at a good price. The incorrect selection of consumables can cause the operation to take longer than planned or cost more than what was budgeted. If an improper grade was chosen, the customer may experience undesired results or pay too much for a grade that they did not require.

When looking at roughing grades they generally have a particle size around 10 to 8 microns. They are used for applications that require no detail and no sharp edges or corners. Because of the molecular and bonding structure in this grade class, you will experience high removal rates at the expense of high electrode wear. Although this grade class machines somewhat easily—due to its structure—there is an issue with it chipping and breaking with small electrodes.

Once you enter the finishing/detail aspect of the grade selection process, you will find that the grades generally have particle sizes from 8 to 5 microns. The most common application for this grade class is forging dies and die cast molding dies. They also can be used in less complex powdered and sintered metal applications, and for larger plastic injection parts. The downfall to these grades is that they are limited on strength and you cannot produce thin fragile electrodes, or superior surface finishes either.

If the workpiece requires smaller and more intricate features, sharper corners, thin ribs or fine detailed smaller electrodes, another grade class usually is required. The fine/detail category will provide the necessary results. These grades usually have a particle size from 3 to 5 microns.

When the application calls for wire cutting, aerospace applications, blow molding, plastic injection, threading electrodes or medical applications, the fine/detail category will meet all of your needs. These applications require that the graphite provides sharp corners, superior surface finishes, and exhibits high strength for small and thin electrode applications.

There are applications that require ultra fine surface finishes, extremely small parts, intricate details on the electrode, best wear conditions, precision or thin wire cutting and superior electrode wear. If this is the prerequisite then the precision class will work best for them. The particle size for this grade class ranges from 3 to 1 micron. It works exceptionally when applied to exotic aerospace type metals (high nickel and copper alloys) and carbide applications.

Finally, there also are copper-impregnated grades that provide an advantage over non-impregnated grades. Typically companies impregnate two classes of graphites: (1) the finishing/detail grades and (2) the fine detail grades.

When graphite is impregnated with copper, micron size particles of copper fill in the holes (otherwise known as porosity) of the graphite structure. By impregnating the graphite with copper it increases the graphite’s electrical resistivity and strength.

Now the electrode manufacturer has the ability to make extremely thin and fragile electrodes, such as a very thin deep rib electrode. Copper-impregnated graphites also are the preferred grades for aerospace applications because the added copper helps to stabilize machining of exotic, copper and nickel alloys.

If you require the finest finish available, impregnated graphites provide the absolute finest finish. Copper-impregnated grades also allow for stable machining when nonfavorable conditions exist—such as poor flushing or when the operator is not very experienced with the application.

Summary

With all of the different grades of graphite available, if an incorrect decision is made, and the wrong grade is used in an application, the result could be costly in both profitability and delivery. However, if educated on what to expect from each grade class and manufacturer, the venture should prove to be a profitable and timely success.

Read Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More