The Designer's Edge: Component Protection

Today Randy reviews how to protect mold components to reduce downtime and repairs, during mold setting, pulling, transporting and storage.

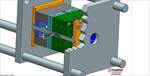

Extended clamp plates protect the components.

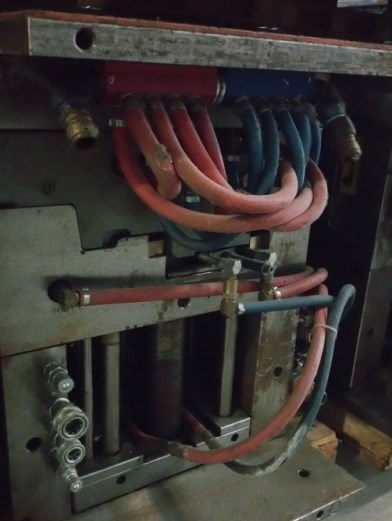

After a mold is set up, it is important to verify the water flow to ensure everything is hooked up properly. Also, when connecting water lines to slides make sure the slide was not bumped out of position or you will damage the horn pin. This typically occurs when using inadequate slide detents or retainers.

Protecting mold components is also important to reduce downtime and repairs. Rails or stand-off pillars should be used when plugs, switches, water lines or cylinders are protruding from the mold sides. Or, use clamp plates that can be extended beyond the mold base for protection. These options will protect your components during mold setting, pulling, transporting and storage.

The mold ejection system should be designed with only the stroke necessary to remove the parts, runner and gates. Excessive ejector stroke adds cycle time, extra mechanical friction and too much unsupported component length, which can lead to wear and failures. Also, only use the required ejection pressures because excessive pressure will cause damage via coining as well as damage to the components if there is any gulling or binding. It can also prevent you from noticing a component failure before it’s too late.

When using tied in knock-out rods verify they are the exact same length and screwed in entirely. This sounds elementary, but I have seen this cause issue many times, such as read-through on the plastic part with ejection. I recommend using four knock-out rods whenever possible. When the mold has suicide conditions, it can also be beneficial to add springs, even when using tied-in knock-out rods. This will prevent damage when pulling the mold. In some situations, the ejectors are run forward to unbolt the knock-out rods and this can cause damage, if the plates are not all the way back.

When using spring return, the spring compression should never exceed the manufacturer’s specifications. Again, this sounds elementary, but springs break. If you have a mold experiencing spring failure, verify the compression.