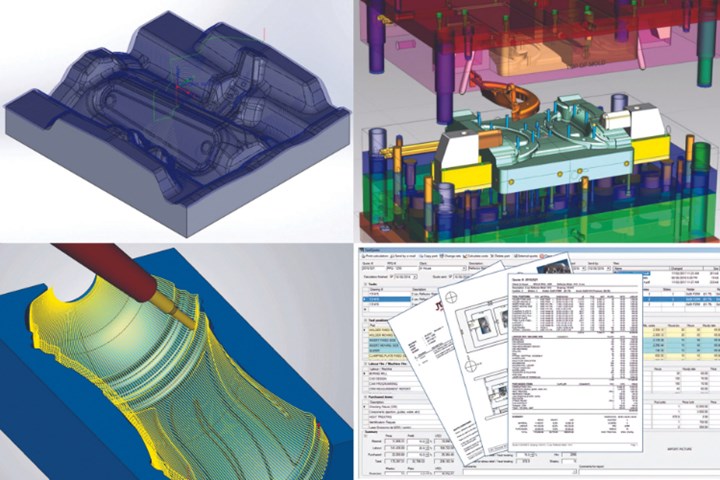

Photo Credit: (top left) SolidCAM, (top right) Longterm Technology Services (bottom left) OPEN MIND Technologies (bottom right) JDL Technical Services.

October is just around the corner and MoldMaking Technology continues to highlights all of the print and digital-only product and service content that its editorial team has received that month from suppliers.

September’s print product/service theme focused primarily on Amerimold exhibitors and their technologies (view Part 1, Part 2, Part 3 and Part 4). For October, we took a look at new and improved software offerings for moldmakers. This article also covers those products that were digital-only, falling under categories such as mold materials and maintenance and repair.

From virtual reality for learning the injection molding process, interactive mold quoting software, CAM software that optimizes blow mold manufacturing and more, October’s roundup has it all. Take a look below:

Hexagon’s Manufacturing Intelligence division reports that it is providing all mold and die shops using its WORKNC CAM software with immediate access to its model preparation software, Designer, integrating production workflows from any CAD model format to CAM so users can machine parts more efficiently and avoid costly errors.

SolidCAM highlights its Integrated Solution, along with iMachining, as an ideal CAM solution for moldmaking.

According to the company, the main challenges for the industry are surface finish, surface accuracy and short delivery times. SolidCAM combines combines several important features to meet these challenges.

The “Circle of Knowledge” offered by Kruse Training is a holistic method that teaches the cause-and-effect behavior in injection molding, helping engineers become all-around molding experts. Kruse Training is an online program that provides an overview of how injection molding professionals, from entry-level to experienced engineers, can benefit from this comprehensive approach. Lessons contain real-world examples of molding scenarios that show how to integrate the training materials in the real world.

Kruse Training is developing what it says is the first fully functional molding shop floor virtual reality (VR) solution. The company says its goal is to create VR classes for injection molding processing in order to prepare users for work on an actual shop floor and are being developed to support a molding company’s hands-on process training initiatives. More specifically, the new technology will enable process engineers to walk and work through individual molding set ups and processing tasks.

Longterm Technology Services has released the latest version of its Dynmik Design for Mold add-on for Siemens NX CAD software. Powered by the Mach 3 Mold Design package, this software has reportedly helped mold designers across North America design more complex tools while cutting their design validation time by as much as 80%. The software can easily be used by CAD designers with less than a single day of training thanks to its streamlined, industry-specific interface.

CAM-Tool by CGS North America has added the competent point rearrangement function to its toolpaths. This has been added into the profile calculation condition window to give users another tool to achieve optimal surface finish.

According to CGS North America, the CAM-Tool is known for its high-accuracy, surface-based CAM calculation engine which generates points directly from the model surfaces instead of using the triangulation mesh that a majority of other CAM systems use.

A simple, intuitive interface enables quoting, manufacturing, sales, support and service departments to all easily view and interrogate 3D CAD files. Initially released in 2018, Kubotek3D’s K-Display View offers mold-specific features, including colored shading based on draft angle, 3D bounding envelope size and measurements of distances, volume, area and thickness.

Tebis America Inc. has launched Tebis 4.1, a complete parametric- associative CAD/CAM system, which is said to provide seamless, highly automated mold, die and model design, development, programming and manufacturing in a single system.

The software platform is built on input from infield designers, for an intuitive and user-friendly structure. Additionally, Tebis 4.1 integrates measuring and production, resulting in shorter setup and machining time, higher component quality and fewer correction iterations.

According to JDL Technical Services, one area often overlooked when trying to improve shop efficiencies is the time spent on RFQs. The company’s ToolQuote Mold Quoting software avoids this oversight by enabling users to quote molds quickly and accurately on a consistent basis. Customers have reported time savings anywhere from 20-80%, achieving quick ROI.

Moldflow analysis services company CAE Services Corp. says it is able to take the guesswork out of the Kentucky Windage process by determining and delivering the proper windage shape ready to cut into a user’s mold block, potentially saving months of rework and tens of thousands of dollars in the process.

R.E.R. Software announces the latest release for its InFocus product suite Version 1.4.2, which has a complete web-based Business Intelligence (BI) tool built into the product. The BI tool comes with several pre-built and powerful web reports, R.E.R. points out, while also providing customers with the ability to design, and create their own custom dashboards/reports.

The latest release of VERICUT, a CNC machine simulation, verification and optimization software by CGTech, offers new features and improvements to preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs. With improved accuracy to collision checking and overall performance, VERICUT’s machine simulation is said to make it easier to verify and optimize an NC program before running it on a machine.

OPEN MIND Technologies, developer of global CAD/CAM software solutions, introduces its latest hyperMILL 2021.2 CAD/CAM software suite which offers users innovative and enhanced features for efficient, user friendly machining in applications ranging from 2.5D to five-axis (see 2021.1 updates). The updated version offers enhanced machining strategies, increased options for data feedback and more convenience overall, according to the company.

CADFlow introduces QuickQuote, a CAD-independent software solution to create quick, accurate and complete plastic injection mold quotations by calculating times and costs based on the 3D model of the plastic part(s). Overall, QuickQuote reportedly limits quotation errors and provides complete information to support the quotes.

According to Hasco, its native CAD databases are well matched to the needs of modern moldmaking. The native data, generated in the original CAD systems—which include installation spaces—reportedly provides users considerable time and cost savings in the design process. Further, CATIA, Siemens NX and SolidWorks databases have now been extended.

RJG’s injection molding networking software, The Hub, has made a new Simulation Support application available. Simulation Support offers the tools needed to launch a tool more effectively, saving time, money and hassle, according to the company.

The Hub connects CoPilot process control systems to a single interface, enabling users to access all plant information from anywhere in the world, make data-driven decision and improve operational efficiency.

There are now three applications available.

New CAM technology has been introduced by ESPRIT CAM, part of Hexagon’s Manufacturing Intelligence division that provides manufacturers with the control and flexibility needed to use multi-spindle and multi-channel CNC machinery for the machining of long parts. According to the company its new software, ESPRIT TNG CAM, offers more accurate simulation of spindle transfers and bar pulls, enabling manufacturers to exploit multi-tasking machinery with high productivity program creation of error-free toolpaths.

CoreTech System Co. Ltd. (Moldex3D) has released the latest version of its molding analysis software series, Moldex3D 2021. In addition to refining simulation capabilities to provide better user experiences, more powerful analysis modules have also been incorporated into the system to meet different customer needs across industries. The important updates and highlights of Moldex3D 2021 are as follows.

New CAM software released by BobCAD-CAM Inc. is said to help moldmakers increase throughput. The company points to SSI Mexico as an example, which develops toolpaths, runs simulations, generates setup sheets and posts g-code programs for all the CNC machines in its mold shop using BobCAD-CAM’s software solution, saving programming time and enabling faster mold production.

Edro, an exclusive U.S. distributor for Böhler, introduces the company’s newly developed M333 Isoplast stainless steel. Manufactured via a new melting technology, M333 offers moldmakers what is said to be best-in-class polishability, enhanced thermal conductivity, optimized toughness and exceptional corrosion resistance.

According to Edro, testing has shown M333 Isoplast to exhibit up to four times the toughness levels seen in 420 stainless steel and almost matching the toughness of H13. This enables molds to have the benefits of stainless steel without the risk of cracking.

Lifting and lashing technology provider RUD has developed a new lifting point for product applications where sensitive surfaces must not be damaged. The TXP-Texolution-Point combines a lifting point base body made from steel with an especially developed eyelet and a textile round sling. Designed to keep the lifting chain at a safe distance, RUD says its product decreases the likelihood of damage to high-value surfaces for some applications, such as class A surfaces and gearboxes.