Succeeding Where Others Fail...

This is the mantra of most every moldmaking company – to find solutions for challenging jobs – and Metro Mold & Design is making it more than a mantra. The Minneapolis-based manufacturer announced its “Making the Impossible” program which targets OEM customers and their supply chain partners with viable solutions for new product development – those products that others would deem impossible to manufacture.

This is the mantra of most every moldmaking company – to find solutions for challenging jobs – and Metro Mold & Design is making it more than a mantra. The Minneapolis-based manufacturer announced its “Making the Impossible” program which targets OEM customers and their supply chain partners with viable solutions for new product development – those products that others would deem impossible to manufacture.

According to Greg Heinemann, Metro Mold CEO, the Making the Impossible program fills an important gap in the marketplace. “Today’s OEM’s are banking on the design or redesign of products to accomplish big business goals. On rare occasions they need a highly creative and atypical manufacturing solution that their current supply base just simply can’t produce. This is where Metro Mold really excels.”

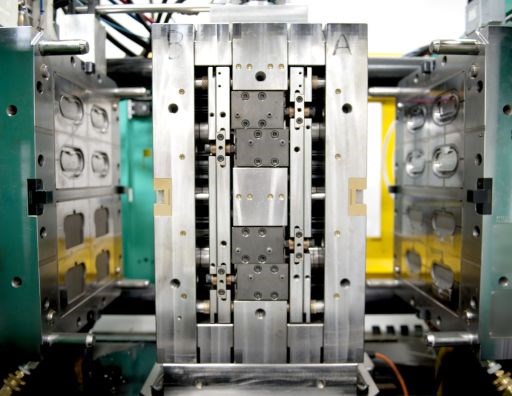

The company’s proven success includes using materials that are extremely difficult to manufacture, creating unique processes that combine molding and machining, and achieving the complex geometries and tight tolerances that often elude other manufacturers.

Learn more about Metro Mold’s Making the Impossible program by visiting its website dedicated to the initiative at www.metromold.com/makingtheimpossible.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

MMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.