Published

Reap The Benefits of Investing in New Equipment!

Over the years I have written a great deal about mold manufacturers who reap the benefits of investing in new equipment. In today’s world of mold manufacturing, it is vital to keep abreast of the latest in technology and equipment to offer your customers complete solutions.

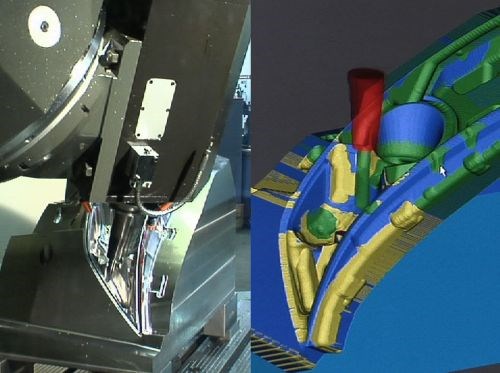

Over the years I have written a great deal about mold manufacturers who reap the benefits of investing in new equipment. In today’s world of mold manufacturing, it is vital to keep abreast of the latest in technology and equipment to offer your customers complete solutions. Past Leadtime Leader winner Minco Tool & Mold Inc. knows this to be true. Specializing in complex surfaces and shapes while serving markets like automotive, electrical, sporting goods, medical and consumer products, the company recently purchased an OPS-Ingersoll Gantry Eagle-1200 with a PC-based CNC control to enable faster data processing and servo control. The machine also has features that allow reduced burn times by up to 50 percent. Read here to see Minco also uses machines like this in conjunction with NX Mold Design and NX CAM from Siemens PLM Software to complete parts quickly and accurately.