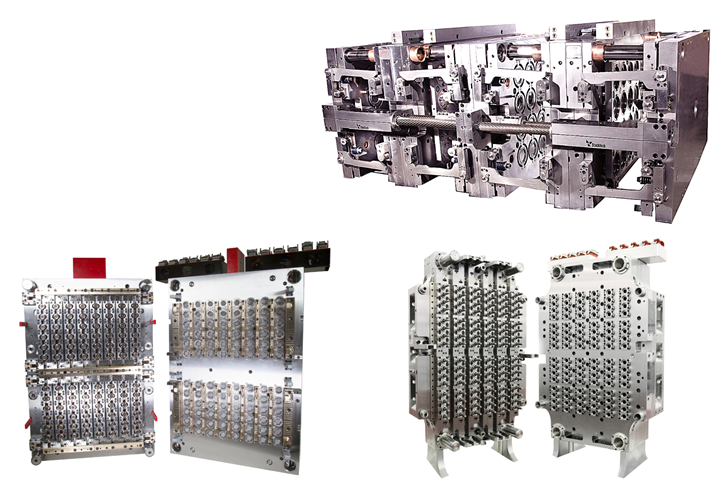

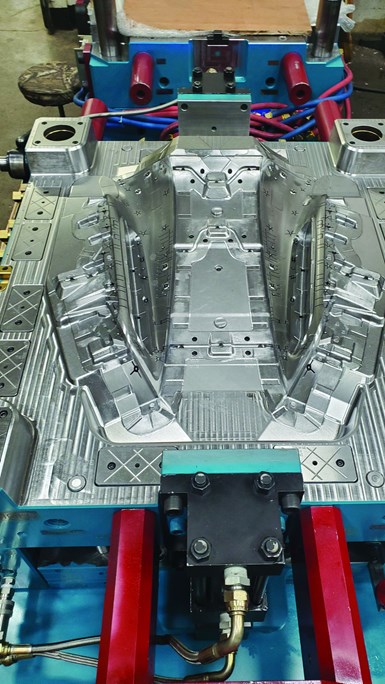

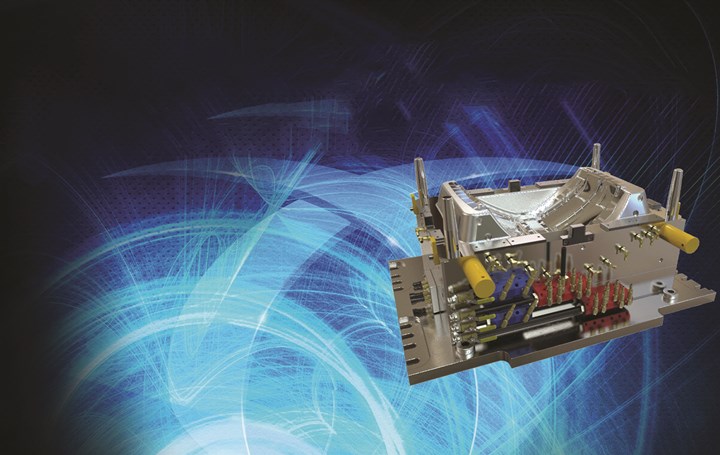

Photo Credit, clockwise from top left: Simoldes Tools, Triangle Tool, Decatur Mold and FET Engineering

The Plastics Technology Expo (PTXPO), taking place this year March 28-30, 2023 at the Donald E. Stephens Convention Center in Rosemont, Illinois, brings partners across the supply chain together, bringing energy and excitement to the show floor.

To provide a little more insight into who our product, equipment or service suppliers are before you arrive at PTXPO, the MMT team put together this special show section* that provides a snapshot of each exhibitor most relevant to moldmaking.

Each profile shares details important to the company’s business and innovations, including why and what they are exhibiting at PTXPO in or around the MoldMaking Pavilion. This round of profiles features Mold Building Services. Booths located outside the Moldmaking Pavilion are denoted with two asterisks and information on where to find them.

Use promo code MMT23 and register today for your FREE exhibit hall pass and we’ll see YOU in Chicago!

*This exhibitor list is subject to change. Current as of 2/16/23

Get to Know AES Advanced Engineering Solutions Moldes Lda

AES is a Portuguese mold engineering organization with extensive know-how and capabilities in the production and management of tooling projects for high-end products and markets. Visit Booth 1231 to discuss your specific projects with members of the engineering and commercial teams.

Photo Credit: AES

AES was founded in 2001 in Portugal. Today, its operations are spread across three continents. The shop designs and manufactures approximately 100 molds a year for various market segments.

Services include project management, product design and engineering, mold design and engineering, moldmaking, mold qualification, metrology, fixture and gauge development and pre-series production.

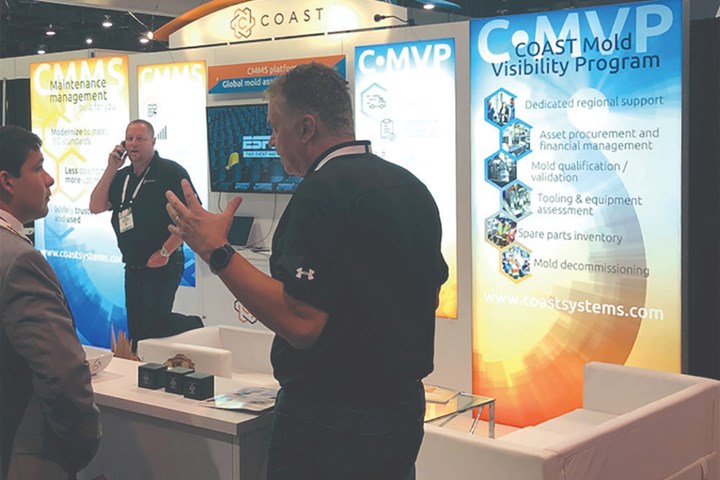

Get to Know Coast Systems

In 2019, Coast Systems moved from a basic computerized maintenance management systems (CMMS) company to a company that focuses on the plastics industry and the tooling and molds associated with it. Since then, Coast seeks to educate potential clients on the technology and consulting services that are available to mold shops that may be struggling to manage inventory or are missing out on opportunities to predict the life cycle of their most critical mold assets.

Stop by Booth 915 and say hello to Jerry Sherman, president, and Bill Cunha, vice president, and learn how Coast Systems can provide a turnkey solution to keep track of molds at multiple locations, while offering increased visibility, life cycle management, project management, engineering consulting and procurement capabilities.

The company’s IoT-enabled Global Mold Management technology is a complete mold management solution that can be tailored to a company’s specific needs. It features a user-friendly platform that enables its users to stay on top of mold inventory control, condition, value, maintenance, repair and replacement, and warranty expirations to maximize asset life and availability.

**Find Coast in the Injection & Blow Molding Pavilion.

Get to Know Decatur Mold

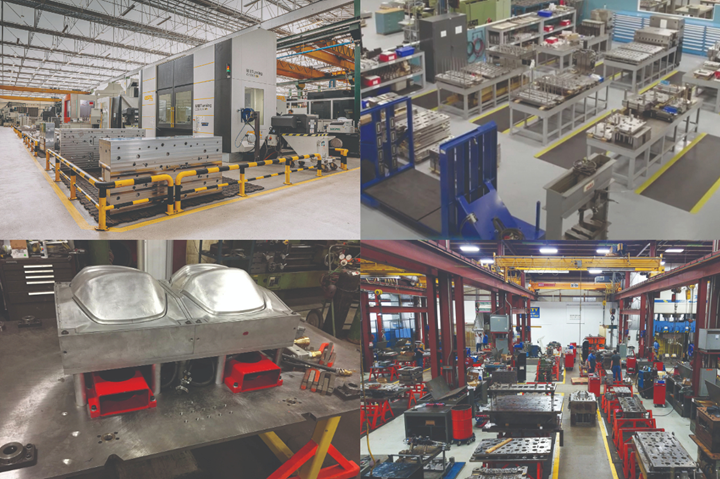

Since its founding in 1966, mold manufacturer Decatur Mold Tool & Engineering has been committed to supporting its employees and customers— the former through providing available jobs within the community, and the latter by delivering at all costs. Today, Decatur continues to keep up, hoping to outrun the ever-changing landscape of inventive technology through its implementation in its daily projects.

One of Decatur’s innovations is state-of-the-art lights-out expansion with 24/7 automation cells to turn around mold deliveries quicker and increase accuracy.

Decatur Mold’s team of technical sales representatives will be on site at Booth 1435 to discuss problems you may need help with, provide company information and educate others on the injection mold manufacturing process. Each representative has a technical, hands-on background in the art of injection mold manufacturing.

Get to Know Minco Tool & Mold Inc.

Minco Tool & Mold started building tools in 1954 and All Service Plastic Molding (ASPM) opened in 1981 to support customer tool samples and production requirements. This enabled the Minco Group to develop into a full turnkey operation. Visit Booth 1328 and touch base with project managers to better understand how Minco and ASPM provide the best of both worlds in mold building and production molding.

Minco staffs 50 dedicated employees and ASPM staffs 400. Together, they support customers by staying current with technologies. Minco and ASPM provide industry excellence in automotive lighting, exterior, interior, under the hood, consumer products, appliance, defense, aerospace, machining, tool repair and maintenance, five-axis machining, wire EDM, ram EDM and CNC gundrill.

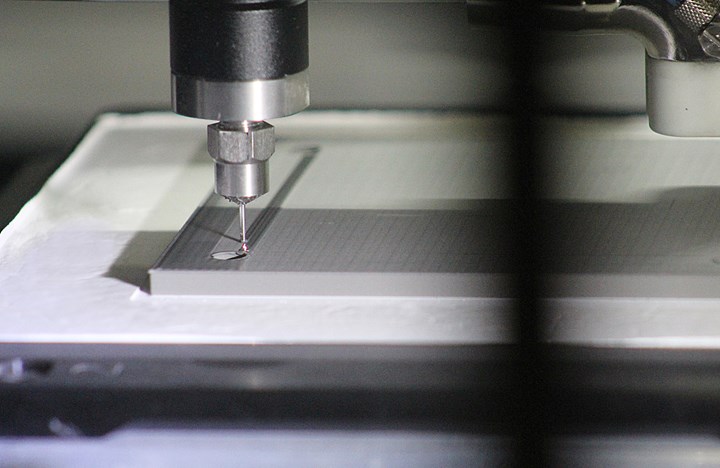

ASPM is able to support press ranges from 55-1,100 tons. Minco boasts a test site for unigraphics software development to improve surfacing and tool paths. Investments in high-speed and five-axis machining have enabled its team to cut directly from the solid model and reduce fitting and polishing time.

Minco builds molds in the U.S., with global partners for those customers wanting hybrid or global mold building.

Get to Know Simoldes Tools

Simoldes Tools innovates daily — in its processes and shop floor and through R&D projects that aim to develop a leaner, more efficient workspace and method. Specifically, Simoldes’ R&D projects aim to develop new materials and applications in its additive manufacturing department (SLM) and new ways to manufacture molds. Visit Booth 421 to get to know the best integration of additive manufacturing (AM) with traditional moldmaking, the company’s project management team and its global footprint!

Simoldes Tools says it is the biggest mold manufacturer in Europe, with a presence in 11 countries around the globe, including Germany, South America, the U.S., India and Morocco. Founded in Oliveira de Azemeis in 1959 as a mold manufacturer for the injection of thermoplastics, Simoldes Tools is a 100% privately owned group of companies that employs over 1,000 workers worldwide. It comprises nine plants and five advanced customer services (ACS). The business not only focuses on molds for the injection of thermoplastics for the automotive and the non-automotive sectors but acts as a solution provider that integrates a complete service from part development to after sales.

In its 63 years of working in mold manufacturing, Simoldes is allied to the energy of young blood and investment in innovative processes, enabling it to manufacture a large number of small to big plastic injection molds in a short period of time at a competitive cost. The company’s project management team are the touchpoint between their client’s needs and their internal team, supplying a complete service from part expertise to after sales.

**Find Simoldes in the Injection & Blow Molding Pavilion.

Get to Know Solution Tools Mold & Die

Solution Tools is dedicated to turning your ideas into great projects! The company helps its partners ensure that their custom part configurations and tooling are dimensionally accurate, competitively priced and delivered just in time.

Solution Tools is a company that has more than 30 years of experience in the molding area, bolstered by a young staff to simultaneously offer clients expertise as well as innovative ideas in today’s volatile market. That is why Solution Tools also has high-tech equipment such as EDM sinkers, CNC machining centers, surface grinders, sophisticated welding equipment, injection molding equipment, 3D printers and high-quality control equipment like a Zeiss Metrotom 800 130 kV industrial computed tomography (CT) system.

In Booth 821 attendees can find Solution Tools personnel to answer questions and samples of some of the company’s final products for which Solution Tools has manufactured molds, from simple to complex. Additionally, there will be brochures and souvenirs.

**Find Solution Tools in the Injection & Blow Molding Pavilion.

Get to Know Triangle Tool, Division of The Plastek Group

Founded in 1956, Plastek is a world-class injection and injection blow mold manufacturer, with three facilities employing over 125 extensively trained toolmakers, engineers and project managers. Engaging with the latest mold design, manufacturing and management technologies and processes, the group led what are now industry standards — designing and building molds for in-press maintenance, the concept of component interchangeability and management practices such as toolmaking apprenticeships.

This has enabled Plastek to provide high-quality, dependable molds with reliable and short lead times. The group uses a CAD/CAM system that is integrated throughout the part design and mold manufacture process for immediate updates and accurate record keeping of valuable part and engineering files.

The theme of Booth 1325 is “Moldmaking, Repair and Reverse Engineering.” Plastek will be introducing Pioneer Automation and its Triangle Tool Divisions — Doug Prischak, VP global tooling and engineering and Nick Prischak, general manager of the Pioneer Automation Division — who are partnering for sealing vertical integration. Attendees will also be welcomed by Plastek’s Corporate Design and Engineering Manager Ken Watkins, General Manager of Tooling and Moldmaking James Jergens and VP Tooling Sales John Heinrikson, who have more than 55 years of combined experience in the moldmaking industry.

Get to Know XMD — Expert Mold Designer — Synergetic Eng. & Manufacturing Services

Synergetic Eng. began over 20 years ago as an expert resource for mold design and consultancy services. Over the years it has evolved into a software development company featuring its premier XMD - Expert Mold Designer software, and then into a fully immersed mold manufacturing company.

Since 1988, XMD has been a mold design automation software. XMD is a knowledge-based, intelligently automated mold design solution that creates, manages, understands and even verifies the hundreds of details of a user’s mold design directly out of the box. This robust, automated design package significantly shortens overall mold design times and further increases the efficiency and accuracy of the design and manufacturing process, in addition to enabling users to design more confidently.

XMD’s ease of use means lower training costs and faster turnaround in having new designers producing at their peak. Speed of operation means lower design cost, and more time for the build process. Increased consistency and accuracy eliminates errors, saving money in manufacturing.

Visit Booth 1420 and meet with the president of Synergetic Eng. & XMD to understand how Synergetic Eng. can help moldmakers and mold designers to be faster and more efficient. Expert mold designers and application engineers will be showing live demos of the automation that XMD provides to all designers right out of the box.

Related Content

MMT Chats: Looking to Reinvent the SPE Mold Technologies Division

SPE Mold Technologies Division Chair breaks down all of the society’s current initiatives. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MorePTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

Read MoreWhat is the Moldmaking Community Excited About?

As we continue to celebrate MoldMaking Technology’s 25th anniversary with a look back over the past quarter century, I asked readers during our recent Plastics Technology Expo (PTXPO) “What excites you about the future of moldmaking?”

Read MorePTXPO Preview 2023: Upcoming Software/Simulation Services, Training and Marketing Solutions

This latest installment of PTXPO snapshots feature companies in and around the Moldmaking Pavilion powered by Amerimold that provide industry solutions in software, simulation, training and marketing.

Read MoreRead Next

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More