Pay for Performance

Transforming moldmaking from a labor-intensive business into a capital-intensive business allows moldmakers to be on similar cost structure to foreign shops and more adaptable for growth than the domestic competition.

With today’s economic trends hampered by escalating costs in all areas of manufacturing, continual liaison and communication with total utilization of resources must be established to ensure timely project completion with maximum costs savings. The necessity for control and maintenance of different engineering transactions required for cost-efficient operations is obvious; however, to achieve success a program of knowledge and experience in all phases of plastics manufacturing must be available.

Mold design/mold building is not only one of the important engineering transactions, but moreover the keystone to success within the injection molding industry. GB Mold has been working with its customers to better align the incentives of moldmaking with the performance requirements of the molder.

The proposal offered is based on the customer’s part design and further investigation into the desired product manufacturing cost models. When we can determine desired cycle time and acceptable scrap rates we can craft a proposal, which consists of a mold cost and a penalty for a mold delivered outside the agreed upon performance specifications. In order to be successful we need to be knowledgeable and in control of two key areas: (1) scientific molding and (2) mold manufacturing.

The injection molding process is comprised of four elements: (1) the mold, (2) the molding machine, (3) raw material (resin) and (4) manpower. The mold is easily 70 to 75 percent of the process. It is the most important, yet the most overlooked as a truly optimized factor to the injection molding process. Throughout the plastics industry the mold is called a tool. The dictionary defines a tool as “Any instrument or apparatus necessary to the efficient prosecution of ones profession or trade.” The key word is efficient. Some antonyms are ineffective, inoperative, negligent and useless.

Upon delivery to the customer, an efficient mold should not only have the mechanical functions optimized (proper steel/shrinkage dimensions, slides, unscrewing mechanisms, ejection systems, manifolds, etc.), but moreover the process values optimized as well.

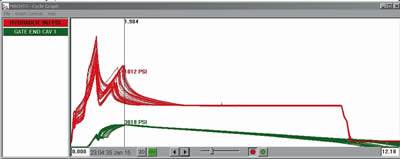

A series of studies has to be conducted, which includes but is not limited to:

- Viscosity shear rate curves to determine optimum filling velocity;

- Segmented pressure loss analysis to determine areas that will narrow the process window;

- Cavity-to-cavity balance within 5 percent weight;

- Gate seal study to achieve consistent final part weight and dimensions;

- Melt temperature versus packing pres-sure/time to achieve widest process win-dow and venting requirements to provide maximum filling velocity and time.

These studies will enable the mold to produce quality parts with minimum acceptable scrap rate at reduced cycle time. A robust process! These requirements are the responsibility of mold builder not the end user.

The time and expense to conduct these process studies are minimal compared to the indirect costs associated with debugging the mold once it has been delivered—such as travel expenses and time for the tooling/process engineers, multiple setup and process times on the injection molding machine, loss of market share for product launch, training, etc.

Since the 1990s, indirect costs have soared while labor costs have dramatically decreased as a percent of total cost associated with design and manufacturing as noted by the Institute for Competitive Design. In addition, according to Forrester Research, indirect costs could amount to seven times more than direct costs themselves. These indirect costs have to be built into the overall cost of the mold even if these expenses are separate budgets. Once these indirect costs are included, the low-cost mold can become very expensive. Being able to determine both (indirect and direct costs) is what separates a wise investment from a crapshoot.

The Mold Building Process

For the molder, in order to maximize the potential of any new mold, he would need to receive from his moldmaker a tool that has been very well thought out as to addition of design features relative to maximizing performance for his particular molding instance.

Any moldmaker offering performance incentives to an OEM or a molder will need to first fully understand the requirements of the program that will be given to competitive mold bidders, including expected molding cycle coupled with critical-to-function details being identified. Then he must be prepared to add to his mold design concept any features, some unique to himself, which have been proven to either improve molding cycle, part quality and/or lessen mold maintenance costs for the given molding application. It is these design features that make the difference in any mold program. Without a robust, appropriate mold design, it really would not make much difference how good the quality of manufacture is in the finished mold itself.

After the moldmaker has determined he has a concept that is uniquely matched to the molding requirements to the degree it will likely out-perform the customer’s performance criteria, he will need to have his manufacturing process in order so he may be able to machine mold details with predictability and consistency so as to finish with the least number of man-hours/overall costs possible. Once again, without this manufacturing equation in order, he may be ill-advised to offer any performance incentive to his customer.

Transforming Moldmaking to Mold Manufacturing

GB Mold in Riverside, CA has chosen a system centering on sound manufacturing concepts to apply to the moldmaking process. It is effectively transforming moldmaking to mold manufacturing. That is, they are assembling a series of standards and procedures that they know to be practical for everyone involved in the process to understand and to apply, which would yield predictable results in areas of design, programming and machining.

GB Mold is coupling that with a palletized system where they mount both electrodes and mold components to pallets and cut everything relative to a standardized, pallet-mounted gage ball. This gage ball also is intended to be the center of the mold component design and programming systems they use. The palletizing is done to speed setup time. The gage ball is applied to not only speed setup time, but to have one point of consistency in which to reference mold design, programming, machining and inspection detail. GB Mold effectively associates its mold design, machine programming and material cutting in-line with the pallet-mounted gage ball. In that way they can certify that all they machine is exactly as all they design and program.

The idea is to drive the mold manufacturing process through mold design engineering and machine programming. In order to do that effectively, it is GB Mold’s master moldmakers who are being trained as mold designers/machine programmers. The main goal is to reduce the highest cost of moldmaking, labor by maximizing untended machining, including lights out night/weekend work. Transforming moldmaking from a labor-intensive business into a capital-intensive business will allow mold shops to be on a similar cost structure as foreign moldmakers and be more adaptable for growth than the domestic competition. Pay for performance moldmaking is a very good way to offer customers something that the competition has not offered.

Related Content

MMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreShift in U.S. Mold Imports: Emerging Countries Gain Ground in Market Share

The dynamic nature of the U.S. mold industry's global trade landscape offers challenges and opportunities for growth.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreDynamic Tool Corp: Leadtime Leader Insights and Bold Plans for the Future | MMT Chats

MoldMaking Technology Editorial Director Christina Fuges gets the scoop from our 2024 Leadtime Leader Award Winner Dynamic Tool Corp., on the company's future, their trade show experience, finding new talent and the impact of this industry recognition.

Read MoreRead Next

Setting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More