On Display at the Windsor Mold Expo

Here is a small sampling of technology that caught my eye.

Note the rounded corners on the “action” end of this lifter from Cumsa. This eliminates the need for users without sufficient wire EDM resources to, say, figure out how to cut square-cornered pockets with an end mill (yes, that’s possible). At the Mold Expo, the company showcased an entirely new design—see below for more.

During a jaunt to Canada a couple weeks back for a shop visit, I stopped by the Windsor Mold Expo. The half-day event consisted of technology suppliers gathered in a single hall with tabletop exhibits of their wares. Complete with a series of technical seminars, the educational opportunities presented by the event far exceeded its size. In fact, compared to some of the larger trade shows, I think the smaller format lends itself quite well to more intimate, face-to-face interactions and deeper conversations, particularly given its focus on our corner of the industry. (Although the event was co-located with the more general Manufacturing and Production Expo, many of those exhibitors could easily have been placed on the mold side.)

Technology offerings covered everything from aluminum mold plates to software to auxiliary plastics processing equipment. Here are three things that caught my eye:

New Vertical Lifter Design. - With the undercut-releasing action occurring within a straight, vertical plane, lifters from mold component supplier Cumsa USA, such as the one pictuerd at the top of this post, often don’t require creating angled channels through the mold (a task typically performed via wire EDM or five-axis machining). The DR (Double Rack) series, shown below, does have an angled portion, but it offers more stability for longer strokes because forces are directed toward the interface of the two sliding bars. Compared to traditional designs, its simplified construction is said to achieve the same travel as within a smaller footprint. This can significantly reduce the size of the overall tool and the required ejection stroke, thereby reducing cycle times and material costs.

As an added advantage, the company is currently working on enabling users to attach cooling lines to inserts actuated by the lifter. Like other designs from Cumsa (see first picture), it also features rounded edges. This enables users to mill the cavity that accepts the unit rather than wire EDM it (or, alternatively, to figure out how to cut square-cornered pockets with an end mill--yes, that’s possible).

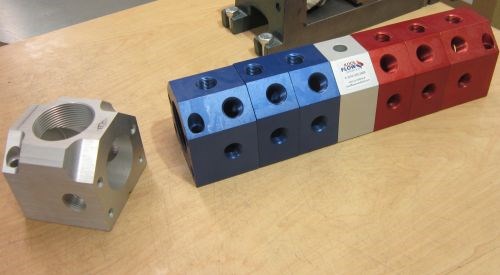

Modular Manifolds. Mold component supplier DMS showcased Kool Flow-brand water manifolds. Consisting of a selection of standard blocks, this modular system enables users to connect water lines to virtually any mold without worrying about specifying particular channel configurations—or worse, ordering or receiving the wrong components. What’s more, assembly is said to be fast and easy, and changes can be made on-the-fly. Other benefits include red and blue color-coding (denoting hot or cold) and the availability of blocks with 90-degree connections, such as the silver one shown below. Read this article for an example of how one shop benefits from the device.

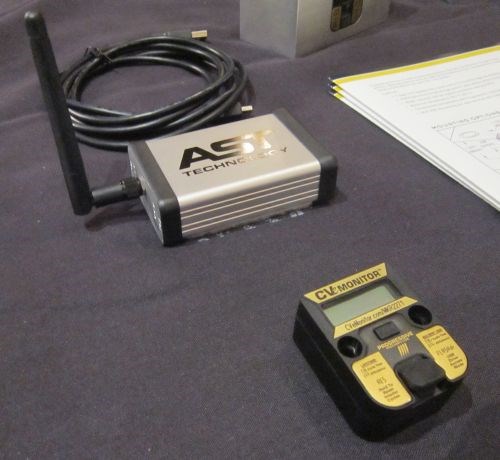

Real-time Mold Monitoring. Progressive Components highlighted the latest version of AST Technology’s CVe monitor. Far beyond a simple cycle counter, the system tracks information such as overall mold efficiency, preventive maintenance and downtime. It also tracks when the device has been removed and/or reinstalled in a tool. In addition to the display itself, users can view the data from virtually anywhere in the world via OnDemand software, available for free, or CVe Live software, which provides real-time mold monitoring and a much more detailed breakdown of data (even down to individual shots). As detailed in this article, the system offers advantages for moldmakers, molders and OEMs alike.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More