Photo Credit: Getty Images

Structured in a Q&A format, MoldMaking Technology’s monthly profile articles offer readers a deep dive into a moldmaking company, typically touching on topics such as culture, technology/equipment/service capabilities and investments and even challenges faced or past/current/upcoming projects. You can even find them in MMT’s digital/print issues!

While these articles are useful to potential customers or readers just wanting to keep up on the industry, they have been particularly important for 2021, serving to emphasize the trials and tribulations—and the successes—North American mold builders have experienced during and coming out of a global pandemic.

Whether it was investing in young talent, seeking out new technologies to stay current or actively improving productivity, quality and customer service, the five shops featured below are only a few of many that continue to make a difference in the mold manufacturing industry, no matter the setback. Based on analytics, they are also the top five most-viewed articles of 2021. Learn more about them below!

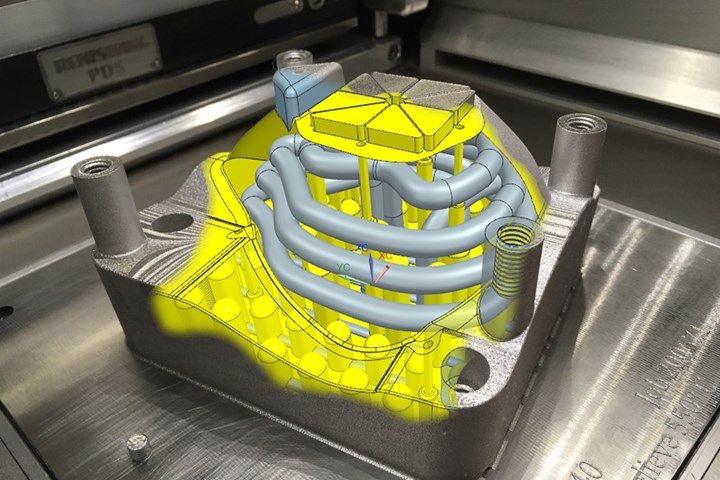

2. Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

Industrial Molds (under parent company Pyramid Molding Group) designs and builds molds for thermoplastics, thermoset, die-cast and insert precision applications for automotive, appliance, electronics, caps and closures, medical, recreational and lawn and garden markets. Its strong team approach enables the company to achieve mold design, build and sampling in record time.

4. Information Is King—in the Shop and with the Customer—at A1 Tool

This mold builder uses information to improve its operation, molds and customer service from data collection to data sharing.

The strength of the A1 Tool Corp. team is engineering and manufacturing complex, multi-shot, multi-action, stack and tandem molds. The company prides itself on fostering a culture based on open communication with customers and continuously reviewing its quality management system (QMS) for process improvement.

Read Next

MoldMaking Technology's Top-Viewed Content 2021: MMT Chats

These top 10 MMT Chat posts from 2021 feature a range of content, from insights on non-disclosure agreements, education on AM, best practices for improving efficiencies and other important topics. Revisit some of your favorites, or take a look at what you’ve missed.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More