Moldmaking Breaks Out of Prolonged Contraction for First Month Since COVID-19

July Index reading exceeds 50 on expanding new orders.

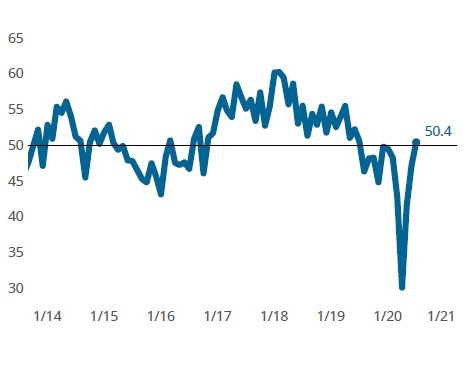

Moldmaking Business Index: The Moldmaking Index not only moved higher for a third month in July, but reported the industry’s first monthly expansion since COVID-19 began largely disrupting the U.S. economy in March.

Registering 50.4 for July, the Gardner Business Index (GBI): Moldmaking marked an important milestone in the industry’s fight to regain lost ground due to the COVID-19 pandemic’s disruption of the economy since March. Gardner’s analysis of the individual components which constitute the Index observed an expansion in new orders and a further normalization of supplier deliveries. The remaining components of the Index including production, employment, exports and backlogs all reported slowing contraction. Among these components, production registered just below 50, implying that production was nearly unchanged from June.

New Orders Expand in July for First Time Since COVID-19: Respondents to the GBI Moldmaking survey reported increased new orders activity in July as compared to June. Other elements of business activity historically follow the trend set by new orders in the following months. Business sentiment and orders activity have also simultaneously improved significantly.

The combination of these events suggests that the moldmaking and molding community may be nearing a floor on the impairment that the pandemic’s entrance has taken on the industry. Historically, the movement of new orders has acted as a bellwether for other components of the Index. From past analyses, new orders frequently lead production activity by one month followed soon after by backlogs. Other measures including supplier deliveries and employment often shadow the movement of new orders by two to five months.

Related Content

-

Steps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

.jpg;width=70;height=70;mode=crop)