Moldmakers as Consultants

Is there any better source for learning new tricks than fellow moldmakers? For that matter, is anyone better suited to critique your own operation and help identify inefficiencies? Open dialogue fostered by the AMBA’s periodic plant tours benefits members in both ways.

The 60-plus shop tour attendees split into smaller groups to move through the two shops more efficiently. Here, members of one such group discuss setup strategies on five-axis machining centers at Eifel Mold & Engineering, which makes extensive use of FCS fixture plates.

The first thing out of John Hill’s mouth when addressing a gathering of fellow mold manufacturers was that he viewed his audience as peers first, competitors second. Competition is global, Hill reasoned, and in all likelihood, North American mold manufacturers will rise or fall together in the coming decades. Learning from one another and avoiding making the same mistakes can go a long way toward keeping customers sourcing close to home rather than abroad.

That sentiment certainly isn’t universal, but I’d be surprised if anyone in the room disagreed. All are members of the American Mold Builders Association (AMBA) who’d come together August 21 for one of the organization’s periodic Plant Tour Workshops. These half-day events, in which moldmakers open their shops for tours and subsequent discussions of their operations, are designed specifically to foster just the sort of collaboration Hill touched on when introducing his own company, Midwest Mold Services. In this case, participants also had the opportunity to tour another southeast Michigan mold manufacturer, Eifel Mold & Engineering.

After introductory remarks, the 60-plus moldmakers bussed over to each of the two shops and split into five different tour groups to keep things moving. Located just a few minutes apart in Fraser and Roseville, respectively, both Eifel Mold & Engineering and Midwest Mold Services had designated separate “stations” (i.e., the assembly area, the design area, and so forth) where guides explained their part of the process and answered questions. Attendees carried two blank cards through each shop: a green card for writing down anything they might duplicate in their own companies, and a red card for noting opportunities for improvement. Afterwards, the group discussed their findings over catered lunch.

Eifel Mold & Engineering credits the tapping arm here for saving significant time in the assembly area. Another thing that made most attendees’ green card lists was use of color-coded CAD drawings visible on kiosks like the one in the background. Among other information, different colors denote different types of operations (a reamed hole versus a drilled hole versus a waterline, for example).

Although the two shops are very different, both have focused resources on a specific niche of customers in the wake of the recent economic downturn. Eifel Mold & Engineering manufacturers between 70 and 80 tools a year. Most are automotive interior molds involving undercuts and other complex geometry that’s well-suited for the shop’s five-axis machining centers, which run unattended about 30 percent of the time. That focus on five-axis was among the items attendees cited as most impressive on their green cards. Others included color-coded CAD drawings that instantly communicate design intent to shop floor workers via kiosks, as well as a home-grown ERP system, which has dramatically improved operational visibility and helped move the shop to a largely paperless environment. However, attendees also pointed out opportunities to automate the generation of bills of materials (BOMs) and to improve workflow (after assembly, parts move back across the entire length of the shop for shipping).

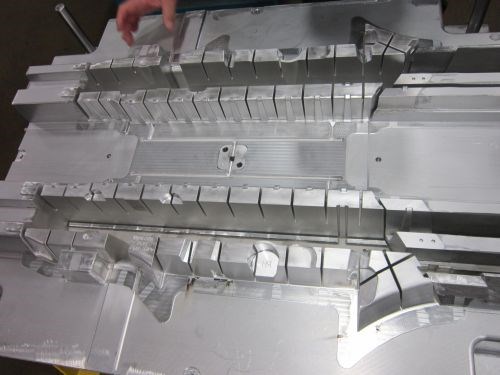

Mounting two blocks on an FCS fixture plate is a common strategy for maximizing unattended machining time at Midwest Mold Services.

Midwest Mold Services also manufactures 70 to 80 tools a year. Unlike Eifel, however, Midwest's work consists primarily of aluminum and steel production tooling that doesn’t require five-axis machining. Still, the shop has invested heavily in the capability to not only make the mold, but also to perform sampling and low-volume production runs in house. And, it’s not as if Midwest is lacking in terms of modern technology on the moldbuilding side, either—the shop makes heavy use of palletized HMCs, for instance. Beyond that, an automated electrode cell; an Ingersoll Eagle EDM that’s said to enable single-electrode burning; and the use of Meta-Lax vibratory stress-relief technology made most attendees’ green lists. So did the shop’s efforts to reduce time at the front end through robust manufacturing feasibility studies and templates for quoting. However, members also pointed out that synergy between the design department and shop floor could be improved.

Tour attendees were quite impressed by this aluminum component at Midwest Mold Services because the deep ribs were milled at a depth of more than 30×D.

Although the above only scratches the surface of the two shop tours, MoldMaking Technology readers may get a deeper window into either of these shops at a later date. After all, I came away with a few ideas for potential articles. For now, however, take a moment to consider the potential takeway of an event like this. An in-depth look at how another shop does things could be invaluable for obvious reasons. Beyond that, consider what it might be like to open your own shop to people who are perhaps better equipped than anyone to criticize your operation. I’d posit that anyone with the courage to do that is serious enough about continuous improvement to offer more than just lip service. I’d also argue that this is just the sort of person you’d want to consult regularly about shared problems and competitive pressures. An event like this provides an ideal opportunity to start such a relationship.

Suffice to say the camaraderie and open dialogue fostered by these tours really speak to what the AMBA is all about (after all, the organization used the slogan “Powering Your Connections” at its annual conference to convey the power of networking.) To learn more, or to find your local chapter, visit the organization’s new website.

Related Content

MMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreMMT Chats: Westfall Technik Talks Runnerless Micro Molds and More

Westfall Technik sits down with MMT Editorial Director Christina Fuges to discuss their new micro hot runner technology, the closeness of the moldmaking community and the importance of integration. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More