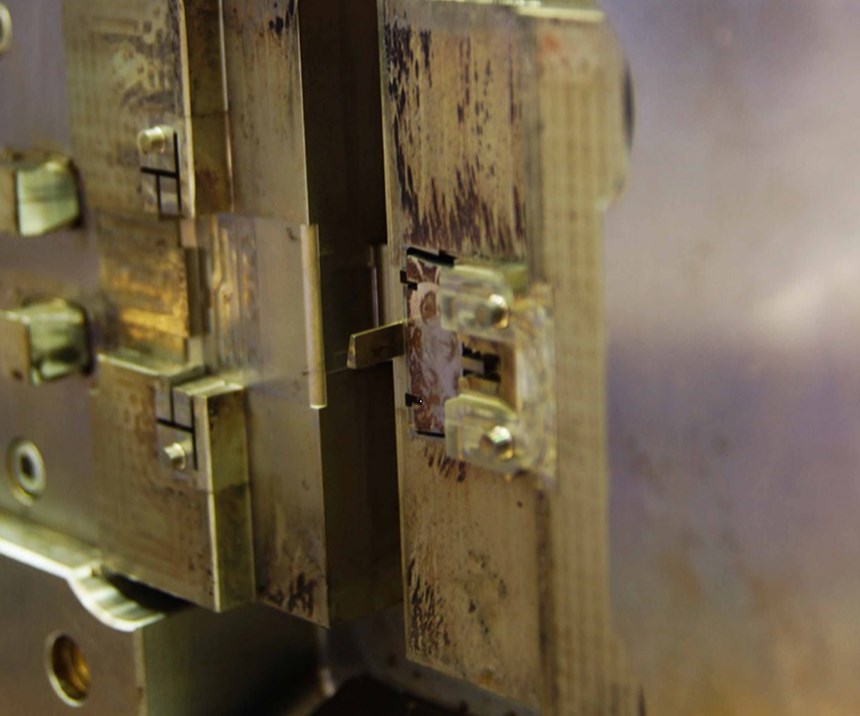

Mold Cleaning Case in Point

The cold hard facts about dry ice cleaning and a system that helps reduce cleaning time and machine downtime by 95 percent while improving process security.

Marquardt GmbH is a German family-owned company with 6,000 employees in 12 locations and nine countries that supplies mechatronic or electromechanical parts for the automotive and household equipment industries. With 100 machines, the company produces around 3,000 different products and one step in the work process was performed manually: the cleaning of the injection molds.

Technicians would remove the mold, clean it and then install and align it again, yielding four-hours of production downtime. In addition, the cleaning was not guaranteed or reliable. The process needed to be optimized.

Marquardt solved this issue with Cold Jet’s i3 MicroClean®-S4 dry ice cleaning system and reduced cleaning time and machine downtime by 95 percent while improving process security.

“The machine gets adjusted and the cleaning work gets done within five to ten minutes, compared with four hours previously. Productivity increased significantly,” Marquardt Product Manager Dieter Stais says.

However, to ensure the system was the best solution, Marquardt tested the equipment for four weeks. With the MicroClean system, the carbon dioxide comes in the form of ice blocks. The blocks are made of carbon dioxide, which is captured as a by-product in chemical or industrial processes. It is reclaimed CO2.

The microparticles are scraped off the dry ice block with a patented shaved ice technology. These particles, in comparison to pellets, have a more refined blasting swath, allowing a more smooth and effective treatment. At the same time, the i3 MicroClean-S4 operates much quieter.

The blast pressure and ice volume are adjustable, and there are different high-performance nozzles. For cleaning wide areas, a nozzle with a blast swath of 2.2 cm is appropriate. The low-flow round nozzle guarantees reliable removal of persistent dirt.

Technicians can also use a 90-degree-angled nozzle for cleaning difficult-to-reach areas and undercuts; and, a rotary union allows the nozzle to turn 360 degree to reach all areas. An ergonomically-designed applicator with integrated LED-light illuminates the areas to be cleaned.

To clean, the mobile and compact device can be easily moved to the injection molds and then connected to the compressed air supply and the static cable. This system permits technicians to clean injection molds hot in the press and without disassembly.

The i3 MicroClean reduced Marquardt’s mold cleaning time by up to 95 percent, according to the company.

About the Author

Steve Wilson is the Global Business Unit Manager – Plastics, Rubber & Composites for Cold Jet. As a former plastics business owner he has over 30 years of experience in injection & compression molding, extrusion, blow molding, thermoforming and rotational molding. He began his career at Milacron’s plastics machinery division, serving in manufacturing, product line management and a variety of sales/marketing roles. Steve is a published author and a frequent speaker at plastics industry events. He holds a Bachelor’s degree in Business Administration from Cedarville University and an MBA from Xavier University.

swilson@coldjet.com

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

-

What You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.