MFG Day Event-Tour Combo Emphasizes Career Opportunities

Micro Mold Co., Inc. and Plastikos Inc. sponsored and took part in a local Manufacturing Day event and hosted students at its facility to emphasize the innovative side of moldmaking and show students how injection molds impact their lives every day.

2,876 is an impressive number, especially when you learn that it is how many events were held during the month of October in honor of MFG Day (and that accounts only for those events registered on the MFGDay.com website). MFG Day was established in 2012 by the National Association of Manufacturers (NAM) and has grown substantially since then. How much has it grown? In 2012, the NAM recorded around 240 MFG Day events, while this year topped 2,870. Of those who participated, the SPI: The Plastics Industry Trade Association reports that more than 200 companies were from the plastics industry.

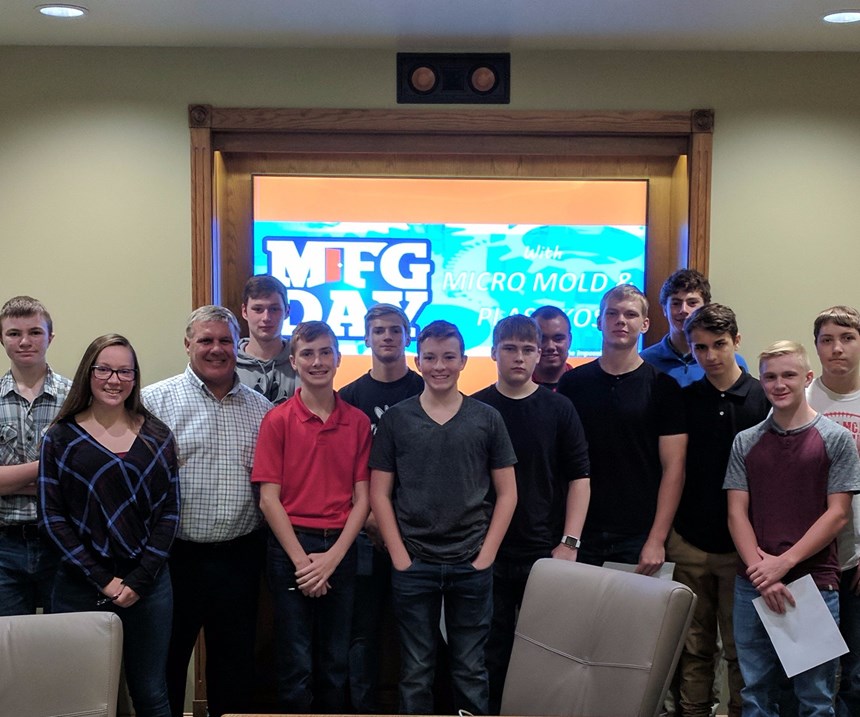

I took a few minutes to scan the list, and found several familiar companies including mold manufacturer Micro Mold and injection molding company Plastikos, Inc. of Erie, Pennsylvania, that did double duty to raise awareness about exciting careers in manufacturing. The companies are affiliated, and on May 11 at the Bayfront Convention Center in downtown Erie to sponsor and exhibit at a MFG Day event showcasing more than 80 companies, programs and demonstrations. Every aspect of the event was designed for the more than 2,000 educators, students and community leaders to experience innovative manufacturing technology in a hands-on, interactive environment.

According to Rachel Curtiss, marketing and communications coordinator, Micro Mold and Plastikos provided handouts to students that explained the various career paths they can take if they worked at one of the companies. Additionally, students and other attendees could experience two interactive “games.” One was called Mix and Match, where students were provided with a basket full of parts and three photos of final products that Plastikos manufacture components for. “The students were asked to figure out which parts go with the matching final product. The idea was to help show them how many parts go into making each final product because, to the naked eye, realizing how many parts make up a final product can be very deceiving when it is fully assembled,” Curtiss says. “We then further explained that each part, no matter how big or small, has to have a mold designed and made for it. This helped them understand what Micro Mold’s sole purpose and responsibility is – to design and fabricate an injection mold from start to finish.”

The second game was called Find the Defect. Plastikos brought an optical microscope from it quality department to the MFG Day event and asked students to examine two sets of 10 parts. Each part had one version that was the “good” part, while the second version of each part contained a defect that made it a “bad” part. “The students were asked to compare the two and tell us when they thought that they had found the defect. We would then go into detail and explain what the defect was, what causes it, and how we try to prevent it from happening. This helped show them the importance of producing a high quality part, so that it can successfully fulfill its role when it is assembled to make an end product, especially when dealing with electronic connectors and medical products,” Curtiss explains.

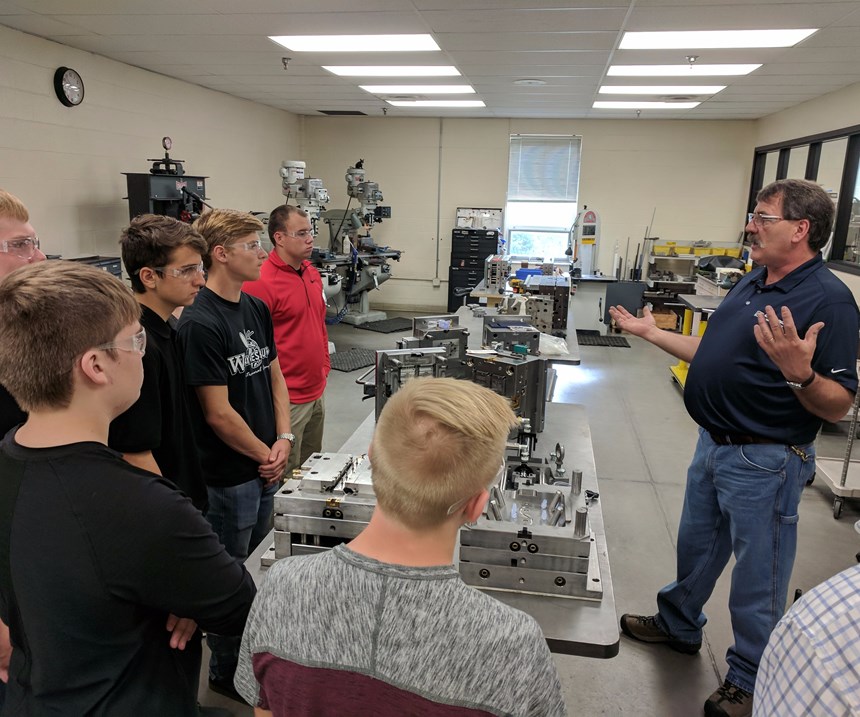

On October 6, the nationally-recognized MFG Day for 2017, Plastikos hosted one faculty member and a group of 14 freshmen and sophomores from General McLane’s Manufacturing Academy, which is a local high school program initiated as a result of the district’s strategic planning goal to enhance STEM education. A plant tour of the entire facility was provided and tour guides discussed essential aspects of the industry, including:

- What an injection mold is and how it works when placed in an injection molding machine

- Quality specifications for parts, and the importance of producing quality parts

- Engineering responsibilities (quality, processing, tooling and project management)

- Tooling, tool maintenance and changeovers.

Curtiss says this year’s group of students “was by far the most engaged group we have had come through Plastikos. They asked a lot of questions and were mostly interested in the tooling side of the tour where we had molds set out for them to view and explained the different features of the mold. They also loved the fact that they were allowed to go right up to our presses to see them in action during the production segment of the tour.”

More MFG Day recaps from mold manufacturing companies will be highlighted soon. In the meantime, check out the images from Micro Mold and Plastikos (above) and read this blog titled A Day Makes a Difference in Changing Perceptions from MMT’s sister company Modern Machine Shop, which spotlights M. R. Mold’s MFG Day event in Brea, California.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More