Making Your Technology Investment Pay Off

If you want to make sure that your technology investments pay off, ask yourself the following four questions prior to each purchase.

Technology typically allows us to do more stuff faster, and generally that can be a good thing. However, it does not necessarily lead to more sales, reduced operating expenses or reduced inventory—and these are the things that determine how much money we make. Technology can bring benefits if—and only if—it diminishes a limitation. This does not mean that if technology diminishes a limitation it necessarily brings benefits—only that it can or may bring them. Even if the limitation is not recognized, the statement holds true. Long before the availability of a technology, we developed modes of behavior, policies, procedures, measures and rules to help us accommodate whatever limitations we have in our system. Our systems do a nice job of accommodating existing limitations.

So ask yourself, what benefit will any technology bring if we neglect to change the rules? If we keep doing things the same way only faster—what benefit will there be? And sometimes the answer is none or very little. If we obey the same rules, we are acting as if the limitation is still there and still being limited. How many companies do you know that have implemented technology of some kind and as a result of this technology their profits have increased substantially? How many do you know that have implemented and have had no results? Which is more common?

If you want to make sure that your technology investments pay off, ask yourself the following four questions prior to each purchase. As an example, we will use a visual scheduling system as the new technology under consideration for purchase.

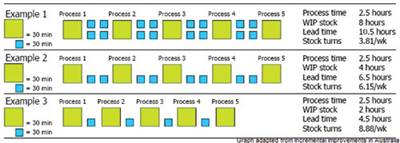

1. What is the main power of the technology? A visual scheduling and priority system provides a method for reducing and controlling WIP, which reduces time through the shop. At a glance, you can see which jobs are the highest priority jobs, allowing everyone to know on what to work. It teaches you how to improve shop communications. It includes a planning component to help determine the release order of jobs and when you need to add capacity to ensure due date performance. It includes a continuous improvement component. It includes key operational and financial metric monitoring to ensure that throughput is growing faster than operating expenses, while maintaining or improving leadtimes and due date performance.

2. What limitation does this technology diminish? The need to constantly update the shop schedule or change promised due dates. The need to add capacity before you have fully leveraged what you have. The need to call customers and change due dates. The need to improve everywhere because you don’t know where to improve to have the biggest bottom-line effect. The need to limit profits by what you can get out the door. The need to limit new business because you can’t deliver what you have on time. The need to sound just like your competitors because you don’t really have a competitive advantage.

3. What rules helped you to accommodate the limitation? Keep everyone and every machine busy all the time and that will maximize the use of resources and efficiencies. If you are efficient, you’re doing the best you can. To increase the likelihood that everyone has something to do, make sure that all orders are available to be worked on. When an important customer calls or an important job is in jeopardy of being late–change priorities in the shop. Whenever you have a little cash, buy new machines. Brainstorm a long list of improvement projects. Schedule when every job will be on every piece of equipment. Measure as much as possible. Track time on every task on every job. Collect tons of bad data.

4. What rules should we use now (with this new technology)? Reduce and control WIP. Stop releasing all the work to the floor to give everyone something to do. Use the rules of a visual scheduling system to deal with emergencies and customer changes. Measure flow not efficiencies. Communicate what to do. Do not detail schedule. Focus on finishing what you started. Use buffers to absorb and manage the variability and mix changes that occur. Track major disruptions to flow and use those to direct continuous improvement. Stop trying to improve everywhere and use the system to tell you where to focus your continuous improvement efforts. Only add capacity where the number one disruption to flow is (or for strategic reasons). Sell more by selling the competitive advantages you created along with quality.

You don’t always need new technology or people to substantially reduce your leadtimes, substantially increase your due date performance or substantially reduce your chaos. I’m not against new technology. I’m against spending money on technology that does not lead to bottom-line results.

Contributor:

“Dr. Lisa” Lang is the President of the Science of Business.

For More Information:

DrLisa@ScienceofBusiness.com / www.VelocitySchedulingSystem.com

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreRead Next

The Secret to Getting On Time and Reducing Leadtimes

Create a competitive advantage by refocusing your job scheduling strategy.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More