Logical, Intelligent Machining

This was the theme of the 2018 ISCAR product launch earlier this month. However, this day-long rollout not only reviewed more than 25 products within the new LOGIQ ISCAR Chess Line, it also addressed the keys to machining logically and intelligently using data exchange, automation and manufacturing technology.

For a mold shop to machine intelligently, it takes three shifts running 24 hours a day. Whether you are high-feed face milling or finishing, roughing cavities, shouldering, pocket milling, drilling, boring, side slotting, profiling, drilling and chamfering, reaming or thread milling, the right cutting tool is essential to improve your overall machining process. This demands a focus on more than the cutter, according to Jacob Harpaz, president of the IMC Group and CEO of Iscar, who warns “not to judge too quickly, as the cutter is not the most expensive part of the machining process.” Shops need to consider the total cost of production verses the cost of just the cutting tool.

One such cost is machine downtime, whose causes include (in order of greatest impact) setup, workpiece change and breakdown. Iscar addresses this downtime by partnering with customers to implement “quick insert index technology”. This approach reduces setup and potential error, converting up to 15 percent idle time to run time. Harpaz advises that shops focus on productivity versus price or tool life, which have minimal impact on cost per part. When reviewing cost per part, we know that raw material, direct labor, machinery and facilities are 22 percent, 26 percent, 28 percent and 21 percent, respectively, while the cutting tool cost is only 3 percent in terms of cost per part. The big opportunity is to use new technology to reduce time increasing profit/hour. Iscar’s ultimate goal is to provide intelligent machining via new cutting tool technology to improve machine shop profit.

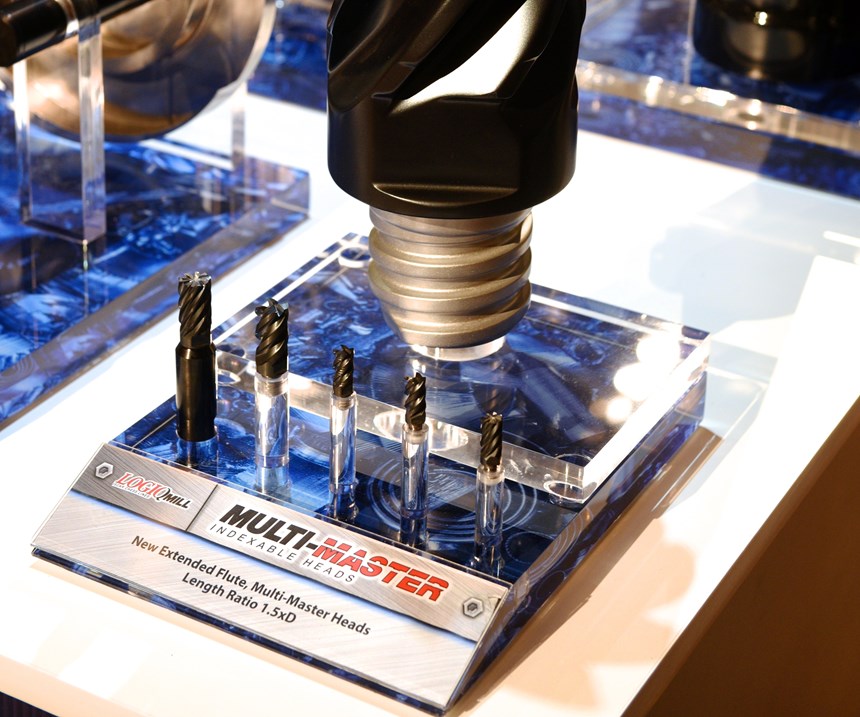

For example, the new LOGIQ product line has many systems that address the smaller workpiece or workpiece features, including LOGIQGrip parting and grooving, LOGIQTurn threading and turning, LOGIQDrill holemaking and indexable, and LOGIQMill indexable and round, which is the strongest line boasting 20-percent growth (see sidebar below).

Typically, indexable inserts can only be used on larger workpieces and workpiece features, but Iscar’s manufacturing advancements helped to produce precision, minature, indexable inserts that can be used where solid carbide endmills are typically used. Working at this scale, requires a different approach than conventional indexable tools. Iscar addressed the “human engineering” for this small tooling by providing extractors that ease the process for replenishing the inserts.

Iscar has released many new feedmills designed to optimize material removal in specific applications. Some are extremely fast, others more economical and still others embrace the smaller working environment. Many machines today have lathes with rotating attachments and the smaller milling systems are ideal for this machining environment.

Iscar has also made big investments in expert systems to apply cutting tools. “We make it very easy for the small to medium-size shop floor to access cutting tool information online to help determine what the best solution is for a given application and to be able to optimize that solution. Plus, we make it available for free,” says Andrew Benson, Chief Marketing Officer and General Manager for ISCAR USA.

All the cutting tool product lines introduced during this rollout event can be used in similar applications, but there's always one that's the best fit for a given application. The challenge is finding that out. Iscar eases this decision-making process by providing comprehensive cutting tool information online 24/7 via its ITA Advisor.

Machining logically and intelligently is also closely connected to today’s smart factories and the current cyber age. The cyber revolution is here, and according to Harpaz, North American shops should quickly embrace what Industry 4.0 really means. They need to move beyond seeing Industry 4.0 as just a slogan, and this will take openmindedness. Industry 4.0 is beyond the limit of one factory. It is connecting facilities across regions, countries.

And technology is the only enabler of Industry 4.0. Cutting tools and Industry 4.0 is all about metrics—a part’s identification, mobile information about usage and sensors to monitor tool condition.

For example, Iscar reports that 15 percent of an operator’s job is spent searching for tools. In addition, 65 percent of stock is never used, and further 20 percent of jobs fall behind due to missing tools. Iscar’s Matrix system is an answer to this waste. Matrix is a total tool management system that helps to control inventory, streamline purchasing and drive down costs. It combines an automated tool dispenser with MATRIX-TM, a powerful management software. Access to an item stored in MATRIX's locked bins is electronically controlled by the management software according to pre-defined authorizations. Matrix is about inventory control, tool control and stock management.

“While we always provide the latest technology to machine the part, the productivity advantage of this technology only matters if you have the tool at the right place at the right time,” says Harpaz. “We felt a responsibility to provide a best-in-class approach to managing the supply of the tool to complement our approach to productivity.”

Per Harpaz’s analogy of the Lion and Antelope, every day, when you awake, you must be moving, and moving quickly to survive. By that he means, shops implement the latest technology and address connectivity use of big data, otherwise they're going to fall behind or worse, put themselves out of business. “People have to address and embrace technology, and that's what we are trying to help them do. Our company is here to improve the profitability of both the large and small manufacturer. The only way to do that is through technology because it creates a level playing field, so the little guy can compete with the big guy,” Harpaz says.

Iscar has a very fast innovation cycle, which was highlighted through the company’s product lifecycle (introduction, growth, maturity and decline). Forty percent of its annual revenue comes from new product and projects. By the time an Iscar product hits the high growth point, there is already more technology in the pipeline being developed. “As a matter of fact, as we speak, the next generation cutter technology is already underway. In the end, we bring the customer profitability because if we make them profitable they're our customers for life,” Harpaz says.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)