It Pays to Take a Close Look at Your Hot Runner Warranty

As innovative companies push hot runner technology forward, a solid warranty can provide the insurance you need to switch to a better hot runner supplier.

In every molding operation, there is great pressure on purchasing agents to reduce tooling costs. When looking for a quality hot runner system, it can be extremely difficult to find the best value for your investment. There are so many considerations to choosing the right solution that it may seem easiest to “stick with what you know”, but exploring your options carefully and looking at different products and warranties can save you money in significant ways.

The Paper Trail

The bold claims of performance and reliability used in advertising and marketing language often seem either far-flung or generic. The reality is everyone claims to have excellent products and services. The real question is, will they stand behind them when push comes to shove? The pricing of systems, usually slow and hard to come by, can also seem less than straightforward. Do the quotations your hot runner supplier provides you with explain and break down in detail what you are getting? Do they include support material that can help you make a better decision, such as online catalogs, technical documents and a comprehensive warranty?

Accurate and overseeable documentation is an essential tool for making an informed decision. Purchasing a hot runner for your injection mold is a lot like buying a car. You should get good performance, reliability and mileage out of your system—all at a reasonable price. Unfortunately, Consumer Reports does not publish data relating to the performance, reliability and longevity of different hot runners, so look for written insurances you can rely on.

Expect More

Take a closer look at your options and you will quickly discover that not all hot runner warranties are created equal. An effective way for a purchasing agent to look behind the supplier’s marketing smokescreen is to understand what’s covered under limited warranty at the time of purchase. As consumers, we have come to expect more from manufacturers. Why should mold investments be any different?

The first task is to find the warranty. A standard warranty document should be easy to find on the manufacturer’s Web site; however, many hot runner companies hide their warranty in the cluttered legal text and fine print of their ‘terms and conditions.’ Some do not share it publicly at all. If a warranty does not exist or has to be requested: Beware. Transparency is a good indicator of companies that stand behind their products and policies.

Critical Components

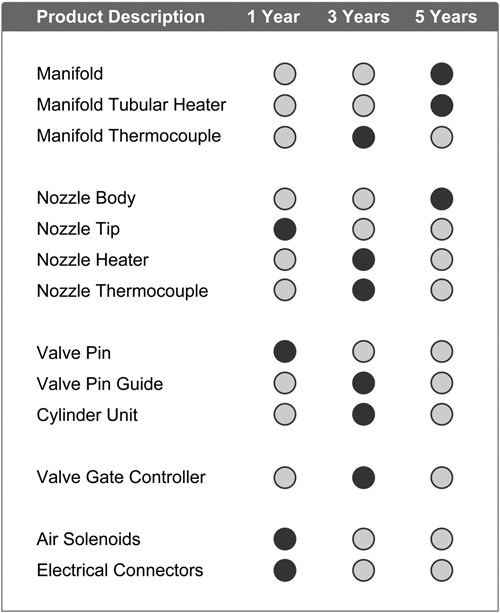

The next step is to look into how the warranty applies to the individual components inside your hot runner system. Manifolds and nozzles, for example, are typically very robust and not considered as wear items. As a result, they often carry the longest warranty period. Since most injection molds have a service lifetime of approximately five years, the molder/moldmaker would be well served to have a warranty that covers the same period. However, manifold and nozzle warranties can range anywhere from one to 10 years. A molder/moldmaker would be faced with a very expensive repair should either of these components fail. Not only would the damaged hot runner component require exchange, but in many cases, the melt leak would flood the hot half, damaging electrical components including the manifold thermocouples, nozzle thermocouples and nozzle heaters.

Get Smart about Heaters

Most suppliers try to build their hot runners based on industry conventions; however, there is no real standard, and you will find significant variations. For example, nozzle heaters can be engineered and installed in a wide variety of ways. This is important to evaluate as a customer because heaters play such a critical role in the function of a hot runner system. Should they malfunction, they can quickly become the Achilles’ heel of the entire molding cell.

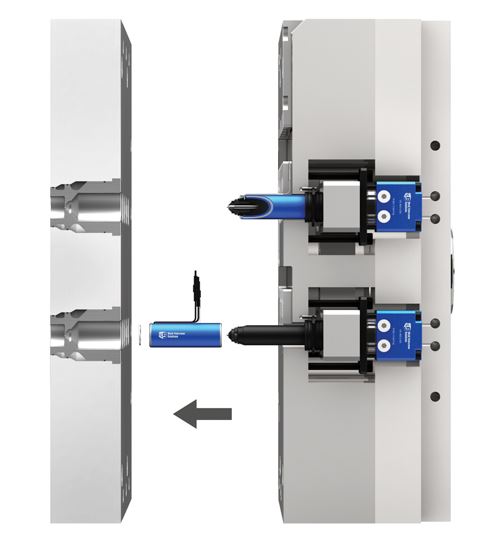

For this reason, heaters tend to be the most common warranty concern in any hot runner purchase. Since no heater is indestructible and subject to aging over time, all heaters should be easily replaceable, not unlike the spark plugs in your car. The faster a heater can be replaced, the lower the maintenance cost. Nozzle heaters are most commonly accessible by stripping the mold cavity plate over to the mold core side. Nozzle heaters that are permanently installed into or onto the nozzle body require a change of the entire nozzle,which means that the mold must be pulled and the manifold taken out of the mold base in order to exchange the entire nozzle. Avoid this type of design, you will pay for it.

(Down) Time is Money

Quickly you begin to see that we are not only talking about exchanging nozzle heaters, but about downtime of the mold. Downtime, not spare parts, is where quality and warranty issues will rack up serious costs. The cost of the downtime is a multiple of the cost of the heaters, whether the heater is covered by warranty or not.

Say a mold produces a part worth $50 every minute, this results in an hourly output of $3,000. If it takes one hour to change a heater, the loss of production is $3,000 in relation to the cost of a $300 heater. In this case, the cost of the interruption is 10 times the replacement heater cost. Realistically, it will take about an hour to replace a nozzle heater while the mold remains inside the machine platens, provided the nozzle heater is easily accessible from the mold parting line by stripping the cavity plate or removing the cavity insert.

The scenario is much more time consuming and costly if the mold needs to get pulled because the nozzle heater is integrated into the nozzle body. Such a repair may take 10 hours and the loss of production would jump to $30,000 due to the heater replacement of a $600 nozzle. The ratio between warranty value and production value is 1:500. This example shows that the ease of maintenance needs to be rated much higher than the warranty value of heaters.

Don’t Wear Out Your Welcome

Some companies boast five- or 10-year warranties; however, a seemingly generous warranty does not necessarily apply to the components that, aside from heaters, contribute to hot runner downtime and preventative maintenance issues. You will find that in many cases these components, typically classified as wear items, are entirely excluded from the warranty. They include thermocouples, tips, inserts, valve pins and valve bushings. When it comes to processing challenging engineering thermoplastics with glass content or a corrosive additive, such as a flame retardant, the focus should shift from heaters to these wear items. The hot runner must be made from more advanced materials. Most hot runner manufacturers will not disclose the materials from which their components are machined. It is the proprietary expertise and application of these materials that increases the longevity of the components, which benefits the molder/moldmaker. A good track record of performance and quality service goes a long way. The only other defense a molder/moldmaker has against uncertainty is the warranty offered by the hot runner manufacturer up front.

Buy with Confidence

Much like the warranty for your car, your hot runner warranty represents the manufacturer’s confidence in their products. Although it cannot drive a purchasing decision on its own, the warranty can be a useful tool when making an informed sourcing choice. It should be better technology (that improves performance, reliability and ease of maintenance) not fear of risk that forms the foundation for a decision maker to select the best hot runner solution for their molding project.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More