PowerINSPECT inspection software

Delcam has launched the 2011 version of its PowerINSPECT inspection software.

This new release makes the analysis of results even easier with the introduction of a "Quick Report" option. It also incorporates improvements to the handling of point-cloud data and easier reuse of measured data to inspect additional features, plus enhancements to the GD&T functionality.

PowerINSPECT is firmly established as the world’s leading hardware-independent inspection software. It combines the ability to work with all types of inspection device with a comprehensive range of inspection routines for taking simple measurements, for inspection of geometric features and for analysing complex 3D surfaces. The resulting reports present detailed information in an easy-to-read format that can be understood by all engineers, not just inspection specialists.

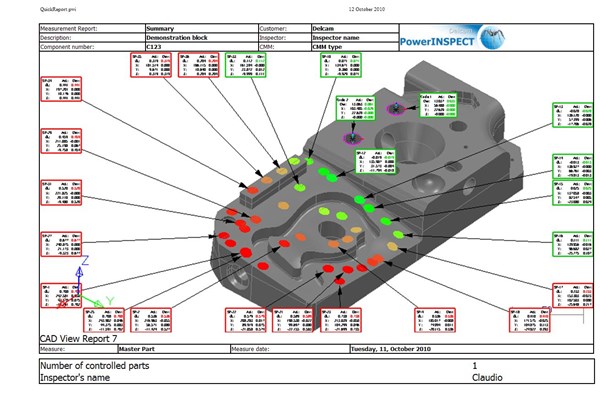

Reporting in PowerINSPECT is now even more flexible with the "Quick Report" option. This allows users to add headers and footers to any image taken from the full report in order to create a single page graphical representation of the inspection. Faster interpretation of the data allows for errors to be identified and rectified more quickly, so reducing costs.

Improvements to the handling and alignment of point clouds make it easier to deal with the large data sets generated when using laser-line probes. Emphasis on critical areas of the part alignment can now be carried out by selecting the desired region of the point cloud and associating it to the CAD. This allows priority to be given to the selected regions of the point cloud rather than treating every point equally, thus giving more control over the alignment.

Points from geometric measurements can now be converted into surface-inspection points allowing them to be used in the inspection of the size and location. This enhancement also allows the existing geometric strategies to be used for surface inspections so reducing the amount of time spent measuring and allowing for more detailed, consistent and cost-effective inspection routines.

Increased capabilities in CAD formats mean that more and more data is becoming available to the inspector in these files. GD&T is the most common Model-Based Definition format and PowerINSPECT now supports GD&T in Unigraphics as well as the previous support for GD&T in CATIA. This lets the user create GD&T items directly from CAD. Improved handling of the tree structure in CATIA files has also been implemented, allowing for easier navigation of the CAD data within assemblies.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

MMT Chats: Predictable Manufacturing and Incremental Gains Can Transform Moldmaking

MoldMaking Technology Editorial Director Christina Fuges catches up with the president of Eden Tool and Eden Manufacturing, Dave Tomic. We talk about predictable performance in moldmaking and the value of small incremental gains in an organization versus big change via disruptive technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Lessons in Quality Assurance for Micro Projects

Quality control, quality assurance and measurement technology are central considerations for micro mold building and molding.