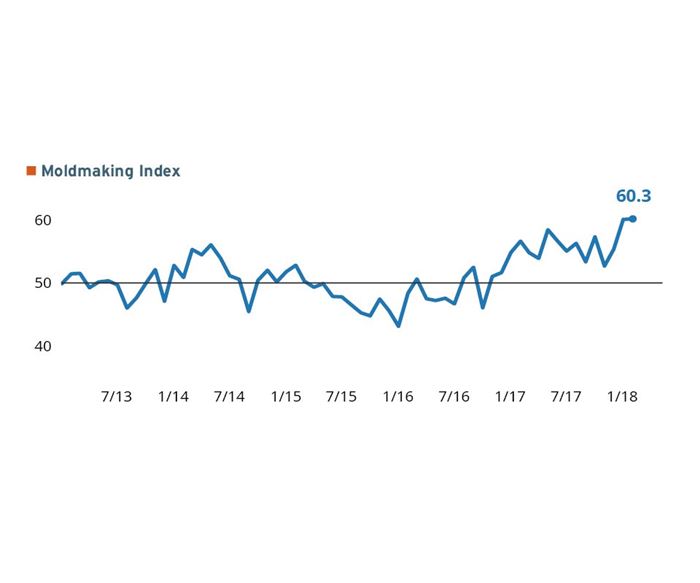

Gardner Business Index: Moldmaking Extends Record Growth Rate

Growth in backlogs are the primary driver of the Moldmaking Index, at 60.3 for February.

The Gardner Business Index (GBI): Moldmaking registered 60.3 for February, extending its record-setting growth for a second month. In comparison to the same month one-year ago and to the average reading for 2017, the Moldmaking Index increased by 6.2 percent and 8.3 percent, respectively. Gardner Intelligence’s review of the underlying data for the month revealed that growth in backlogs was the greatest driver of the Moldmaking Index in February, followed by production and new orders. All three of these measures recorded multi-year, record-setting growth rates in February. Employment, supplier deliveries and exports pulled the Moldmaking Index lower. Exports and supplier deliveries showed slowing rates of growth. No components of the Moldmaking Index contracted in February.

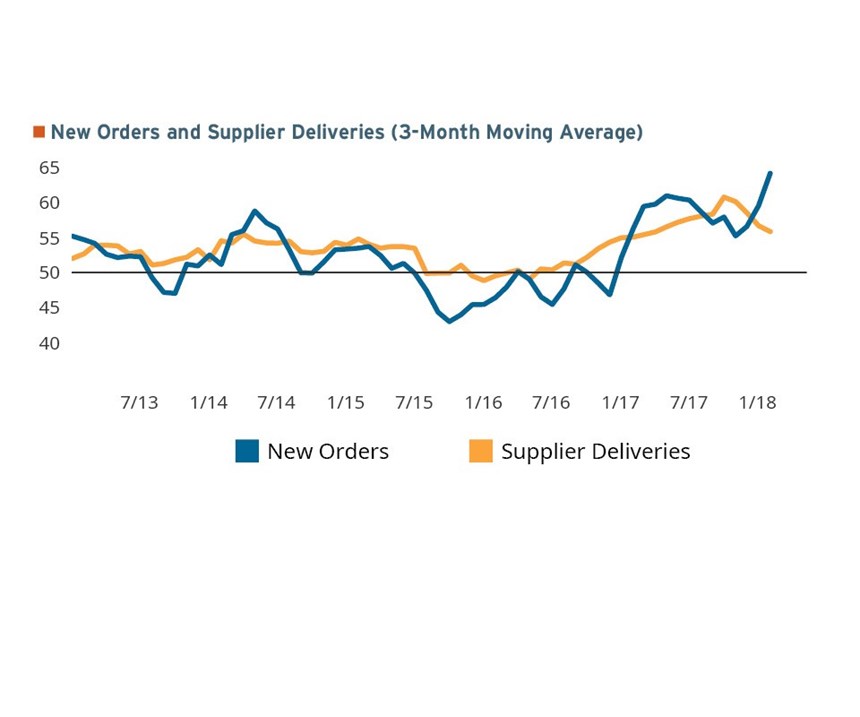

Unprecedented growth in new orders in 2018 has sent shocks through the industry. Moldmakers have responded by increasing production to rates that it has not experienced since 2012. Yet, through February, backlogs continued increasing despite increases in production. According to the data, supplier deliveries have yet to appreciably respond to strong growth in new orders and growth in backlogs. In comparison to the prior month’s reading and the reading from February 2017, supplier deliveries are growing more slowly at present.

Unprecedented growth in new orders in 2018 has sent shocks through the industry.

In a pattern similar to the Moldmaking Index, survey responses only for custom processors in February indicated significant industry expansion for a second consecutive month. In recent periods, the overall growth in the Moldmaking Index has outpaced the growth for custom processors. Robust readings in new orders and employment from custom processors in February narrowed this gap.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Get Social and Be a Part of the 20th Anniversary Coverage with #MMTMag20 on Twitter, LinkedIn and Facebook.

Related Content

-

Moldmaking Accelerated Contraction in June

June’s moldmaking index took a relatively steep downward turn, landing at a new low for the year.

-

May Moldmaking Index Trends Downward

Contraction, experienced by most May components, continues to be familiar territory for the GBI: Moldmaking Index.

-

Moldmaking Activity Accelerated Contraction in July

July’s moldmaking index accelerated contraction for the third month in a row, though the magnitude was considerably less than last month.

.jpg;width=70;height=70;mode=crop)