Energy and Electronics

Energy is Leading American Manufacturing; Electronics Receives Reshoring Support

Energy is Leading American Manufacturing

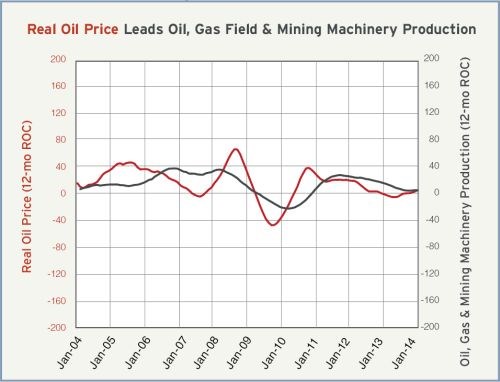

Energy may be the strongest part of the American economy. In recent years there have been significant new finds of oil and natural gas. Because of these finds and the high price of oil, there was significant investment by the oil and gas industry in capital equipment in 2010, and such spending should ramp up again in 2014. This is partly due to the fact that the price of oil is starting to grow again, which should lead to growth in the production of equipment used to get oil and gas out of the ground.

But perhaps a more significant reason for continued investment in energy is the relative price difference between oil and gas per BTU. Currently, oil is very expensive per BTU relative to natural gas. While there has been a great deal of investment to get natural gas out of the ground, much of the natural gas being produced is simply being burned off. However, the relatively low cost of natural gas should spur a great deal of investment in American manufacturing for its use. The U.S. needs new pipelines, trucks and tanker cars to move the natural gas around the country. Port facilities need to be built for possible natural gas exportation. Then there is investment to convert those goods that run on oil to run on natural gas. In 2014, our surveys show that there will be significant investment by pipe, pump and compressor manufacturers.

You can see all of our data related to the energy industry at

gardnerweb.com/forecast/oilgasmining.htm,

forecast/powergeneration.htm

gardnerweb.com/ and gardnerweb.com/forecast/pumpsvalvesplumbing.htm.

Electronics Receives Reshoring Support

Most people wouldn’t know it, but electronics production in the U.S. has grown at an exponential pace since the early 1970s. This is largely because electronics spending in the U.S. has grown annually every single year for at the least the last 40 years. In addition to this continually growing spending by U.S. consumers, the electronics industry is receiving further support from reshoring. In January, Foxconn, most known for manufacturing products for Apple, announced that the U.S. was a “must go” market for its manufacturing operations. The company stated that it wanted to be closer to the product development and design teams of its major customers. And it probably doesn’t hurt that the relative cost savings from Chinese labor has all but disappeared.

While spending on electronics is still growing, it has been growing at a slower rate for the past six months or so, and electronics production has been growing at a slower rate for most of the last three years. But it appears that electronics production has slowed a little too much. The rate of growth is flattening and may start accelerating again in 2014.

Our business index shows that the electronics industry has been on a bit of a wild ride recently. The index has been trending down since July 2013, although new orders appear to have broken out of this downward trend, which could be a sign the industry will start expanding again. In contrast to new orders, production has been on a general up trend since the fall of 2012.

You can see all of our data on the electronics market at

gardnerweb.com/forecast/electronics.htm.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.JPG;width=70;height=70;mode=crop)