Doosan Intensifies Focus on Milling

At its recent technology fair in South Korea, the machine tool builder revealed innovations that could bring greater balance between milling and turning sales here in the U.S.

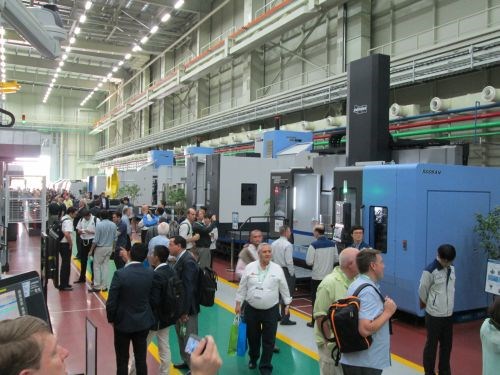

Attendees tour Doosan’s new Seongju factory, which began operating in January 2014. Situated in close proximity to the primary production facility in Namsan, this location is dedicated to production of large equipment, including milling offerings such as boring mills and double-column machining centers.

Approximately 150 dealers, customers and Doosan employees from the Americas visited the machine tool builder's Changwon, South Korean manufacturing campus May 12-15. Although that delegation represented only a fraction of the more than 4,600 attendees at the 10th iteration of the Doosan International Machine Tool Fair (DIMF), the company has big plans in store for North America in particular.

Compared to those in most other areas of the world, manufacturers here purchase fewer milling machines than turning machines from Doosan, says Andy McNamara, director of sales and marketing at U.S. arm Doosan Infracore America. He adds that although the company is among the top 5 machine tool suppliers here in the 'states, it's not as big of a player in mold manufacturing compared to other markets. He and the rest of the team at the machine tool builder's U.S. arm aim to change the equation.

Between the factory tour displays and the main exhibition area, shown here, DIMF 2015 highlighted a total of 83 machine tools, ranging from machining centers to lathes and even Swiss-types. At least half of those offerings were milling machines.

In fact, McNamara, a relatively new hire, says his own background is strong in milling. Additional application engineers have also been hired, largely for their expertise in milling. Some of those new hires will further specialize in five-axis machining and mold/die, respectively, and the company has also added a technical specialist for large products (many of which are mills). This deeper knowledge in North America is backed by ever-more-capable machining centers coming out of South Korea, McNamara says.

Check out this slideshow for more specifics on some of those machines, many of which could be of particular interest to mold manufacturers. The technology showcased at DIMF includes some relatively new developments that reveal much about Doosan’s future direction. Examples include direct-drive spindles with Big Plus interface, linear scales, linear roller guideways, multiple axes, and capabilities for both heavy hogging and larger parts.