Cutting Tool Refinements Improve Production Levels, Tool Life and Tooling Costs

A roundtable of cutting tool technology suppliers give their input on common cutting tool challenges, trends and solutions for today’s mold manufacturers.

Today’s mold manufacturers constantly push the limits of cutting tool technology while searching for innovative machining approaches mostly because of the complexity of the shapes and features they must machine. This requires them to keep up on the latest advancements and refinements in this market.

When it comes to cutting tools, today’s mold manufacturers are looking for longer tool life, reduced cutting tool costs and increased production levels. Common challenges to these goals include the need to hold tighter tolerances, increase throughput and productivity, maintain good finishes, reduce time to complete a part and decrease rework.

Following is a general overview of a variety of cutting tool technology developments from a handful of leading suppliers that can help address these challenges—including advancements in coatings, tool geometry, design, edge preparation, hard milling and optimized roughing.

Advancements and Trends

Overall, the continued development of new cutting tool technologies will be geared towards addressing the competitive nature of the moldmaking industry, as moldmakers demand efficiency, productivity and reliability, according to Stephen Jean, Milling Tools Product Manager at Emuge Corp.

Tom Benjamin, Product Manager for Walter USA agrees, noting that customers set the trends in their respective industries and they develop tooling to address these trends. He says one such development is the “machining of molds and dies in a hardened state (from 48 to 70 HRC) along with tighter tolerancing of workpieces, which provides more flexibility for the moldmaker.”

Similarly, according to Bill Greenleaf, National Sales and Marketing Manager for Greenleaf, there is a trend in R&D for newer insert grades and coating technology advancements, which affects the mold builder, designer and process as they relate to the ability to both rough and finish the mold completely in the hard state.

“This dramatically cuts setup time as all cutting processes can be performed after hardening. Whisker-reinforced ceramic inserts can cut at very high speeds and feedrates, and withstand temperatures that would melt a carbide cutter. This coupled with their ability to cut extremely hard alloys significantly increases mold shop productivity,” says Greenleaf.

Gary Meyers, Seco’s Milling Product Manager sees things moving in a similar direction, noting that the mold industry’s increased workload has motivated shops to invest in state-of-the-art equipment to effectively tackle hard milling applications and increase productivity. “In fact, the dynamic method for milling is becoming increasingly popular, especially when using solid carbide cutting tools. This process requires higher feedrates and higher RPMs that newer machine tools can provide,” says Meyers.

Dynamic milling is an optimized roughing approach that combines large cutting depths with relatively small radial engagement when cutting steel up to 60 Rockwell and harder. Peel milling is another name for this method.

“With dynamic milling, the toolpath constantly adjusts to ensure the most efficient cut possible by maintaining constant chipload and engagement of the cutter. The toolpath is also optimized for maximum material removal rates. The tool’s entire flute length is used, which helps eliminate the need for multiple depth cuts,” explains Meyers.

On a related note, as more shops consider dynamic milling, some software companies have added techniques for this process in their programming software. “With the required CAM programming, dynamic milling can increase removal rates by up to 300 percent when compared with traditional methods,” states Meyers.

Tom Raun, Specialist—Machine Tool OEM and Industry Projects for Iscar Metals, Inc. shares a similar theme when it comes to CAM and cutting tools, “Along with creating innovative cutting tools, ways to make it easier to use cutting tools within CAM and simulation software environments is a focus. This should be useful in the mold manufacturing environment where redundancy is not the norm, programming often becomes a bottleneck and verification in a virtual environment is critical before taking the process to the machine. In a nutshell, we’re looking to automate CAM inputs with cutting tool outputs, which in turn puts years of cutting tool experience at the fingertips of programmers.”

Another significant move seen by Sandvik Coromant continues to be to lightweight, high-speed machining, which offers lighter, faster machining and techniques that effectively use the abilities of machine tools today.

Troy Stashi, Industry Specialist–Automotive/Milling for Sandvik Coromant, explains, “We are seeing a reduction in the use of ballnose endmills in favor of round insert cutters (button cutters). Although ballnose endmills have historically been the tool of choice in moldmaking operations, button cutters are able to perform the same techniques while offering security and low tool pressure when machining at high feeds and speeds. Importance is being placed upon the further reduction of tool pressure without compromising reliability. Similarly, machine programming/modeling software are being developed, bringing new machining techniques into the industry and placing new demands on future tool designs.”

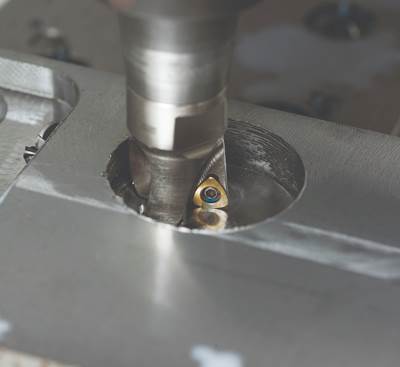

Back at Iscar, Raun explains the continued trend to push the envelope of indexable cutting tool technologies, especially for milling applications. “One example is more double-sided inserts for milling cutters, a design that normally doubles the number of cutting edges on an insert and creates the most efficient and effective use of carbide purchases. One might think this is nothing new and although this particular argument would be correct, it comes with some big exceptions. The makeup of tools today (and the near future) contain geometries, edge preparation and rigidity needed to aggressively shear material and last longer in a wide variety of materials, which are also evolving and becoming more difficult to machine,” notes Raun.

Other trends observed in the mold market according to Dave Povich, President of Tool Alliance/RoundTool Laboratories, include refinements of tool geometry, design, coatings and edge preparation as manufacturers continually modify and improve designs to maximize tool performance.

“The use of diamond-coated carbide tools continues to expand, with PVD-DLC diamond coatings offering excellent value and performance,” says Povich.

Toolmakers are also looking to improve tool performance through surface finish improvement and edge preps/hones. “Micro-blast, lapping and brush hones reduce the coefficient of friction on the cutting surfaces and also improve edge integrity. The results are finer workpiece finishes and extended tool life,” notes Povich.

To sum up, there are several key things that cutting tool manufacturers continually redevelop and reengineer, according to William Fiorenza, Product Manager—Die & Mold, Ingersoll Cutting Tool—Member IMC Group. They are unique insert geometries, carbide substrates, cutting edge preparations (example hones) and high-tech coatings.

“I see cutting tool manufacturers leveraging these four design elements/features even more in order to optimize cutting performance. Many cutting tool manufactures are now even rethinking how certain indexable insert geometries perform better with certain types of toolpath algorithms generated by advanced CAM software. I also foresee cutting tool companies working more closely with customers in trying to teach the importance of the overall machining process. Specifically, what key machining variables need to be addressed (optimized) to make their cutting tool technologies run at peak performance,” says Fiorenza.

Offerings and Developments

To specifically address the aforementioned challenges and trends a number of offerings and developments are on the market and underway.

Over at Sandvik they are working in partnership with their customers, machine tool makers and technical universities to develop solutions, which has led to a stronger focus on tool design with light cutting action in combination with high reliability. “Due to this, we are striving to connect our tools with the new machine technologies and material trends, bringing innovative machining techniques to this industry, which allows our customers to best utilize the rapid increase in technology available to them,” notes Sandvik’s Stashi.

Greenleaf has a new class of both ceramic and carbide insert grades optimized to rough and finish hard mold stock. New ball nose, bull nose and high-feed cutters, screw-on modular heads and carbide shanks with extended lengths are all products aimed specifically at the moldmaking market.

Bill Greenleaf adds, “A solution for getting longer tool life and reducing cutting tool costs is to eliminate the singular solid carbide tool and replace that with a toolholder arrangement that can accept both carbide as well as ceramic inserts. Indexable inserts are far less costly than refurbishing a solid carbide cutter and allow for dramatic reductions in setup time. A refurbished cutter many times does not cut as well as it did when it was new, while the cutting surface of the indexable insert is always new.”

To accommodate dynamic milling of a wide range of steels, Seco recently introduced a new high-performance four-flute square shoulder end mill with a long cutting edge and built-in chip splitters—Jabro™ Solid² JS554 3C. Meyers explains, “Because dynamic milling quickly removes a lot of material at a very high feedrate, the process often creates pile-ups of big, long chips. This new end mill solves this issue by using its chip splitters to break the chips up into to a small, manageable size. Furthermore, its full cutting length and chip splitters, when combined with the dynamic milling method, generate increased levels of productivity and higher tool life due to a consistent load.”

Walter USA has launched a new milling family specific to the machining of hardened materials, Protomax Ultra. “This product allows for increases in metal removal rates of up to 100 percent versus conventional type tooling in these harder materials,” notes Benjamin. In addition, Walter has a multi-level service program to service its customers and optimize the entire cutting tool process. Areas include planning, manufacturing, logistics, maintenance and training.

For its developments in CAM with cutting tools, Iscar has partnerships with CAM companies, like Mastercam, which according to Raun, “are key to getting our existing cutting tool data to speak with CAM software and to making programming more effective and efficient. Every input that can be automated reduces the likelihood of a costly error and increases the odds of the cutting tool being used to its fullest potential.”

To meet the efficiency, productivity and reliability demands of today’s moldmakers, one example from Emuge is its Duplex tools—including Multi-Cut Duplex and Jet-Cut Duplex, which are part of the company’s High Productivity Cutting (HPC) end mill program.

“The Multi-Cut Duplex end mills feature a flute design, permitting rapid material removal in construction steels typically used in mold manufacturing. These tools also feature technology from the Time-S High Feed indexable insert cutter, achieving exceptional material removal in a similar range of materials. Combined into one tool, these features provide the ability to rough machine in a variety of environments—including into deep cavity detail or deep pockets, as well as perform 3D milling and 5-xxis machining, all with a single tool. Similarly, the Jet-Cut Duplex combines our HPC finishing end mill and Time-S High Feed milling technology into a single tool, capable of semi finishing, finishing and hard machining in material up to 66Rc. These versatile Duplex tools are made from a wear-resistant carbide applied with a high heat resistant coating for optimum tool life to repeatedly perform a range of machining operations that would typically require a number of end mills, of multiple styles to accomplish,” according to Jean.

Over at Ingersoll Cutting Tools, new technologies that leverage optimal cutting geometries and special coating processes are always being developed and/or refined. “One example is the new GOLD-RUSH grades that have proven to be a real performance enhancement. This new coating technology stabilizes and extends tool life in continuous and interrupted cutting operations; reduces cutting friction and minimizes built-up edge on exotic materials; offers high surface finish on the workpiece; and, improves coating adhesion and insert chipping resistance,” says Fiorenza.

Tool Alliance/Round Tool’s Povich focuses on workpiece finish and tool life. “The need to achieve a specific finish may require custom or modified geometry and design. Increased tool rigidity or a geometry that cuts more freely may be needed to achieve a better finish. Longer tool life is always desired, yet some tool life requirements are specific to a given workpiece. Through the use of specific carbide grades, coatings and hones, we are able to finetune tool performance and provide the required cut time,” explains Povich.

The carbide cutting tool brands offered by Tool Alliance/Round Tool include several proprietary processes—including the SmoothGrind® grinding process that provides finer finishes on key cutting edge surfaces; SmoothCoat®, SmoothContricity® and SmoothEdge®; as well as SmoothFlute—a patented variable helix geometry. “These processes combine to create cutting tools that provide the highest level of milling value and performance,” says Povich.

Summary

Just as important as moldmakers keeping up on the latest advancements and offerings in cutting tool technology is getting your technology suppliers involved early in the process. Everyone benefits when each link in the chain is communicating and collaborating—moldmaker, machine tool supplier, cutting tool manufacturer, software supplier, etc.

Sandvik’s Stasi sums it up nicely, “We can best benefit our customers when we work closely together with them from the beginning—from component design, through to machining strategy. Challenges like productivity and cost savings can be addressed through optimization in the early stages of a project and for any other challenges, an open-minded approach, while looking at the whole process, is a must.”

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)