Selection Process for Stainless Mold Steels

Successful production of plastic components associated with the extrusion, injection and compression molding greatly depends on the mold material selection.

There are many factors to consider when selecting a stainless mold steel.The final plastic part requirements are the most important factors to consider when selecting the proper mold material. Cosmetic requirements, resin type and filler content are the main considerations along with the expected tool life.

The second category of factors is the manufacturing and servicing conditions in which the tool is expected to perform. These include production environment, expected cycle time and tool manufacturing variables: heat treatment, weldability and machinability.

Component Specification Factors

The type of resin is an important factor to consider when selecting a mold steel. Many of the resins—when exposed to elevated temperature—will emit a corrosive gas. Polyvinyl Chloride (PVC) resins operating at 165°C will release hydrogen chloride when combined with humidity to form a corrosive hydrochloric acid (HCl). In addition, cellulose acetate will also create a corrosive reaction by forming ethanoic acid at elevated temperatures. Corrosion of the mold steel may also occur when processing resins with fire retardant additives. Chlorine and bromine base flame-retardant additives can become highly corrosive to the mold steel.

The type of filler is another critical factor. Typically glass-filled resins will be more abrasive to the mold steel and a higher steel hardness should be used. If the resin is corrosive and has abrasive fillers, a stainless steel grade should be selected and the hardness should be maximized to a level suitable for the design. When corrosion is a concern—either with the resin or filler—stainless steel cavity and mold base material should be considered as an alternative to plating or coating regular tool steels.

When the final molded product requires high cosmetic requirements, SPI ratings A1-A3, Electro-Slag-Remelted (ESR) mold steel should be selected. In the ESR process, the original ingot is remelted in an environmentally-sealed vessel protected by an inert gas. The ingot is remelted, droplet-by-droplet and the dense steel falls through a controlled slag and re-solidifies in a copper mold. The slag acts as a filter, absorbing oxides and sulfur impurities. The fast re-solidification results in a dense homogeneous microstructure with little segregation and low inclusion content. The ESR process assures the best conditions for cosmetic finishes. After the ingot is remelted, it is further processed through a proprietary diffusion annealing, forging/rolling and heat treatment cycle.

High production tooling should use the most suitable material regardless of the cost associated with material and heat treatment. Typically material costs are less than 15 percent of the total tool costs. Downtime and premature failure costs outweigh the additional material costs. In regards to low production tooling and prototypes, it is appropriate to use the least expensive options meeting all of the requirements of the final product. When polishability is a concern, ESR material is still recommended.

Manufacturing and Service Factors

The environmental conditions of the molding facility should be well understood. In high humidity regions, with warm climates, the mold steel will have a tendency to oxidize resulting in parting-line degradation and pitting of the molding surfaces. A stainless steel mold material should be used in these situations.

In addition, when the PH and chlorine levels of the coolant water are not closely controlled and properly adjusted, a careful evaluation of the stainless steel grade and hardness should be considered to minimize the risk of inter-granular stress corrosion.

When using 420 grade stainless steel, the proper heat treatment is critical. The shape and size will ultimately determine the proper heat treatment process. The typical specified hardness for 420 stainless in mold applications is in the range of high 40 to low 50 HRc .

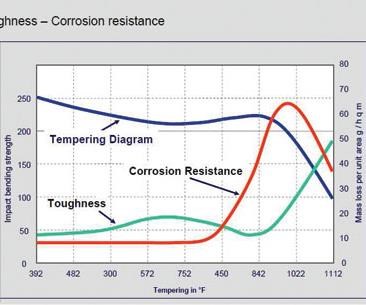

There are two ways to achieved this desired hardness range with either a lower or a higher tempering temperature. Depending on the tempering temperature, the corrosion resistance and toughness will be greatly influenced. In addition, 420 stainless has a sharp tempering curve at the higher tempering range and there is a risk of missing desired hardness.

Often, if the hardness is the only specification, a heat treater will use the lower tempering temperature, which will provide the maximum corrosion resistance but with the lowest toughness. There is a trade-off with this material between corrosion resistance and toughness and, therefore, an experienced heat treater should be consulted when determining the heat treatment process parameters (see Chart 1).

When selecting a mold steel, weldability is usually the least considered factor; however, with many applications—especially with new product launches—engineering changes are necessary and weldability becomes important.

In other cases, based on customer and/or tool history, it is usually well known what areas of the tool will be prone to engineering changes and repairs. In cases where welding is expected, a low-carbon precipitation hardening stainless steel should be considered. The lower carbon content will limit the formation of a Heat-Affected-Zone (HAZ) and eliminate the need for a post-weld heat treatment cycle.

In these tough economic times, there is a trend to use pre-heat treated grades in order to eliminate the additional costs and time associated with the heat treatment cycle. The latest technological enhancements achieved with high-speed machining have provided the opportunity to machine prehardened materials in a cost-efficient manner, thus eliminating the multi-step process of roughing, heat treatment and finishing.

Tool steels have much lower thermal conductivity compared to copper beryllium materials. It is recommended to insert these high conductivity copper beryllium materials in areas with heavy wall sections and near the injection components where thermal dissipation is needed. There are several alloys with hardness ranging from 20 HRc to 42 HRc.

Conclusion

The selection of the right stainless mold steel grade greatly depends on the application. Understanding all of the factors in advance can determine the success of a project. Look for a material supplier with years of experience in tool steel production, heat treatment, laboratory services as well as sales and technical support.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Vacuum Heat Treating of Tool Steels

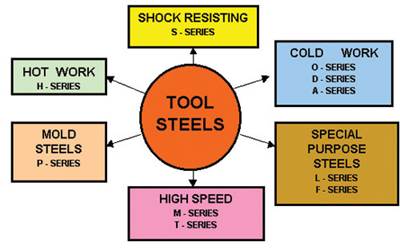

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools, however, special attention needs to be paid during their heat treatment so as to achieve the best properties for a given application.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More