Counting One’s Blessings at Christmas and Always

Because it’s Christmastime, we celebrate the season with lights, parties and gift giving. But in addition to those festivities, some are also focused on, as they say, “the reason for the season”—The birth of Baby Jesus.

Because it’s Christmastime, we celebrate the season with lights, parties and gift giving. But in addition to those festivities, some are also focused on, as they say, “the reason for the season”—The birth of Baby Jesus. The folks at Ameritech Die and Mold Inc. in Mooresville, North Carolina, are among them.

Steve Rotman, who is owner and president of Ameritech, shared with me his strong Christian faith several years ago, when I saw him at an American Mold Builders Association conference. But he reminded me about it when he responded to a few questions I had about the company’s new automation division, which I’m writing about for MMT’s February 2017 issue. I asked him to explain how Ameritech Die and Mold South, which is the company’s second manufacturing facility in Ormond Beach, Florida, came to diversify its market focus and serve the government and aerospace industries. He replied with a story that, like the automation division’s founding, was based on a turn of events and good timing. In other words, fate.

“We were always aware that offering machining services for military and aerospace customers could be a way to diversify and yet be complementary to mold making, so it had been a point of discussion amongst the managers,” Steve said. “The issue was none of us knew how to go about breaking into it. In 2009, a gentleman approached us and dropped off his resume. He had his own aerospace/government machining company while residing in Kansas. He told us he had moved close to our Florida facility to help take care of his parents, and when he had fulfilled that situation he started looking for precision machine shops that looked like they would have the equipment and talent that he knew he would need to get back into the aerospace/government machining industry. Because we were open to it already, it was a complete shoe-in to move forward and see what we could do.”

Then Steve said this: “We call it God’s Marvelous Hand of Blessing! Chuck is a Christian and when he interviewed I let him know that we were a Christian-based company. His eyes lit up and the rest is..a miracle!” That’s when I asked more questions, as editors will do. I asked him to elaborate on his Christian-based company culture and how they represented it in their shops.

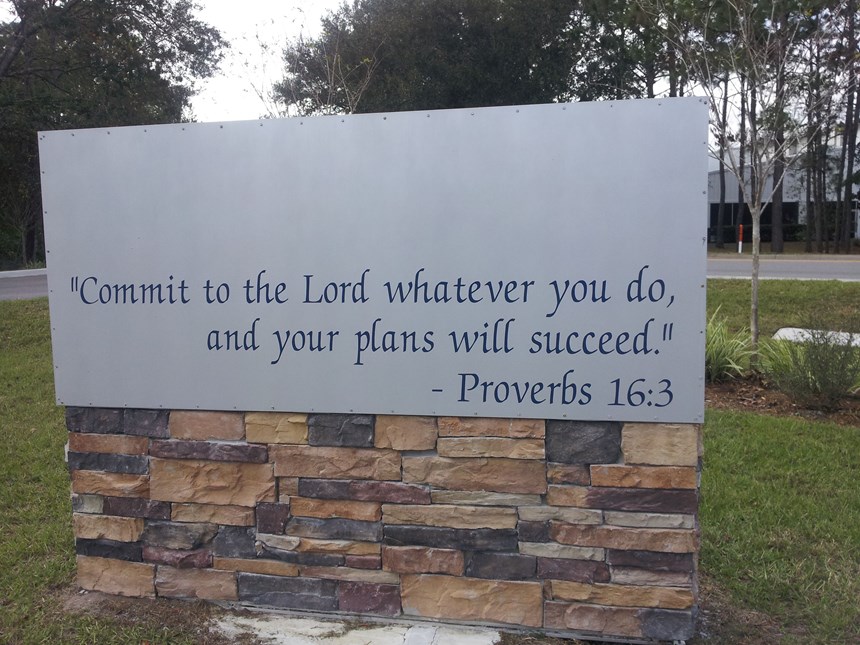

His response was to send me three images (shown with this blog, above), and this reply: “We do not usually put up decorations but we have a Christmas party for each facility and both are opened with prayer, as are any other food-based meetings we have internally.” He added that Ameritech supports ministries through donations, including year-round advertising on the local Billy Graham Evangelistic Association radio station, which Ameritech has done since 2002. “We’re not expecting to get any business, but feel it’s a way to help provide Christian-based radio for anyone driving through our area. I myself look for the Christian radio stations when driving so I feel it’s important to do our part to provide for it in our area.”

Interestingly, the day I was asking Steve about all of this, his son, Rusty, division manager of Ameritech South, shared a note from a customer who appreciated the Christmas card they sent him. “We always make sure that the content in our Christmas cards is Bible-based, and that is what this gentleman is referring too,” he says. “I have had employees on local customers’ floors thank me for advertising on the BGE radio station. I love to hear that. I can’t tell you how many times I have been stressed about something, jump in my car to run somewhere and hear that ad, and it just melts the stress away as I am reminded of God’s Hand upon us. Yes, I have other Christian-based customers/contacts that we openly discuss our faith and challenge each other with things going on. I feel that all the great things that have happened to me personally or through the companies has God’s reflection in each thing.”

It's good to express one’s faith and give thanks, not just during Christmas, but year-round, and, as you’ll see in the photographs above, Ameritech's faith-based culture shines through in many ways, and there's nothing wrong with that.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More