Constructive Criticism

Feedback from a molder helps this shop deliver what customers want.

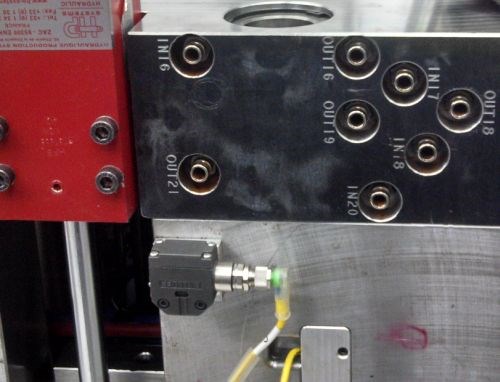

The markings shown above, which identify fittings for water hookups on a plastic injection mold, are there for one purpose: to make things easier for the molder using the tool. Such markings are common to many of the tools built by Industrial Molds Group, a Chicago-area shop that strives to make molds as user-friendly as possible, says account supervisor Kerry Smith.

This push for user friendliness is a result of frank but constructive criticism from the molder that does most of Industrial’s sampling. Taking such feedback to heart has helped Industrial better ensure it is delivering what customers want, Smith reports. And, that’s just one example of how both organizations benefit from their close relationship. Click here to learn more.