Conformal Cooled Molds Are Not Just for Small Molds

If you appreciate the amount of true engineering that goes into a design like this, ask yourself if the U.S. automotive industry is behind the curve by not using more and advanced conformal cooled molds.

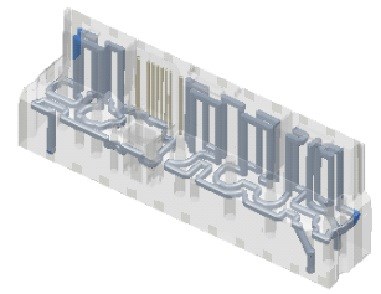

Here is a large automotive European part that is a conformal cooled mold. To design a conformal cooled mold, the designer needs to have an understanding of the resin's properties, dynamic heat transfer, the effect of fluid dynamics on heat transfer, and the creativity to design using an understanding of material properties.

He may also want to use FEA to verify that his design is strong enough to take the loads. If you appreciate the amount of true engineering that goes into a design like this, ask yourself if the U.S. automotive industry is behind the curve by not using more and advanced conformal cooled molds.