Competition is Good

Losing business overseas motivated this moldmaker to re-engineer its tools, improve its processes and stand by its customer, ultimately winning the business back.

Phil Malenfant, owner of Neovision Technology, based in Windsor, Ontario, Canada, has seen more innovation and changes in the way molds are built within the past 5 years than in the rest of his 30 years as a toolmaker. Molds today produce better quality parts, run faster, last longer, have shorter lead times and cost significantly less, and Malenfant says that we have China to thank for this—but not in the way you might think. We didn’t learn any new tricks from China. China just forced us to innovate and become better at what we do.

Let the Games Begin

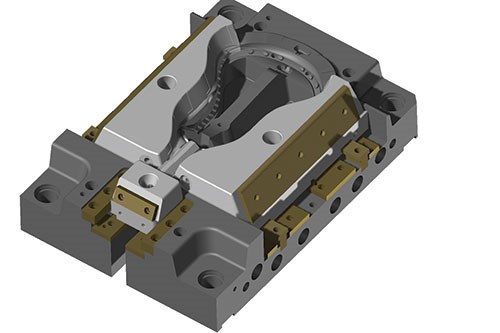

In 2007, Warrior Sports, a sporting footwear, apparel and equipment maker headquartered in Warren, Michigan, was looking for a new mold builder to manufacture some intricate molds with very complex parting lines for lacrosse heads. The company selected Neovision because of its reputation and experience in insert molding.

Neovison built its first tool for Warrior in 2008, and the customer seemed very happy with the tooling. “We thought we had a customer for life, but because of corporate pressure and current market trends, Warrior announced they would start sourcing some lacrosse head tooling in China,” Malenfant says.

By the end of 2008, Warrior had placed the order for its first batch of tools in China, and by 2009 all Warrior tools were being built there. “We knew it was coming, but we didn’t expect it to happen so quickly,” Malenfant says. “The price difference between our two quotes made me feel powerless.” After closely comparing both quotes, it seemed impossible that Neovision would ever be able to compete again.

“When the first batch of tools went to China, we all secretly hoped the rumors of dirt floor mold shops and shoddy workmanship were true,” he admits. “We hoped that first batch would be the last. It wasn’t the case.” The tools were built on time and were of decent quality. They weren’t perfect, but, for the price, they were good. Malenfant knew all of this because he maintained his close relationship with Warrior. Neovision continued to pay attention to the sporting goods company’s needs and communicated (and listened) regularly. This helped the company learn what Warrior liked and didn’t like about building tools in China. Once that was understood, Neovision was able to offer solutions.

Time Out

When Warrior first started sourcing tools in China, the company was thrilled with the savings it was seeing on paper. However, as time went by, the challenges associated with a long-distance mold builder relationship started to eat away at Warrior’s patience—and savings. Shipping molds back to China for a repair or change was cost prohibitive. Warrior had to contract with local companies at a premium to work on these Chinese tools, which were more complicated.

“The trend in China is to make a mold from as many pieces as possible,” Malenfant explains. “Labor costs are not an issue, so they can have many people working on many pieces at the same time. This allows them to get the job done quicker. However, this does make Chinese molds more complicated to repair when things start to wear out.”

He also notes that the extra travel costs were so significant that they were eroding much of the potential savings. However, when Warrior eventually increased the volume of tools it was building, that cost was divided across more tools and therefore had less of an impact. It actually increased the company’s costs savings.

“That’s why companies often move all their tools over,” Malenfant says. “The problem with this is the added time and effort required. In one of our many conversations with Warrior we discussed how the extra travel time and workload was negatively affecting productivity and quality of life.”

Building tools at a distance has other challenges, as well. Communication is a huge problem that often affects collaboration and innovation. Typically, Warrior would rely on its domestic moldmakers for expert advice, but with overseas moldmakers that proved more difficult. For example, many times moldmakers can suggest slight part changes that can simplify the mold and reduce complex mechanisms. This type of communication was lacking from China.

Back in the Game

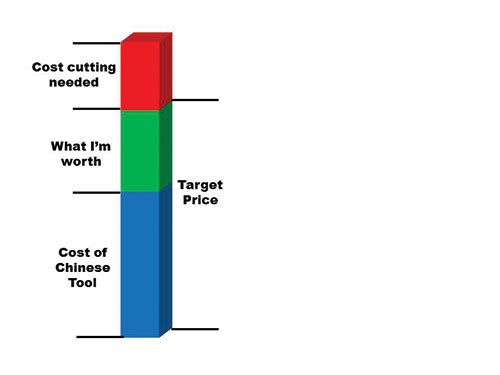

Neovision continued to listen to Warrior’s problems and was finally able to ask, “What are we worth to you?”

“I worked with Warrior to quantify the problems,” Malenfant says. “For items such as travel costs and repair/change savings, determining a value was easy. However, items such as innovation were more difficult to translate into hard numbers. For example, better tools as a result of our expertise and input. The most difficult value to define was ‘how much do you like working with us.’ To put it simply, I don’t choose a restaurant by looking for the cheapest steak per ounce. I’m willing to pay more for the ambiance, food quality and wait staff professionalism. The same applies here. The fact that your customer likes to work with you, you offer better quality and professional service, and you make his life easier has real value. It’s not an easy conversation, but it’s a critical one in order to compete.”

Once Warrior and Neovision agreed on a value, they calculated a target price (see graph).

• Chinese Tool Cost + Neovision’s Worth = Target Price

• Neovision’s Quote – Target Price = Necessary Cost Cuts

“Finding the target price was easy, but figuring out how to build tools to meet that target price was a real challenge,” Malenfant notes. Profit margins became tighter. Neovision had to improve accuracy.

“If we made a mistake before, we could make it up in other areas, but now there is no margin for error,” he says. “To ensure fewer mistakes, teamwork was vital.”

Neovision had to examine its entire mold-building process to become more efficient, because the playing field with China was no longer even. Steel, component and machining costs became much more significant. The company had to figure out ways to make tools for less money without compromising quality.

Re-engineering their tools from the ground up was Step 1. “We looked at everything and started asking why,” Malenfant says. “Why is that slide so big? Why do we need that much steel? When you start asking why, you would be surprised how many times the answer is ‘That’s the way we have always done it.’” Engineering calculations revealed many places where Neovision could safely remove steel and minimize component sizes.

Time was another critical factor. Neovision could not compete with overseas labor costs, so it had to learn to work smarter, which required employees to work and think like a team.

Malenfant explains: “Typically, the person responsible for roughing a job made decisions based on his/her machining time. The goal was to get the job off their machine and onto the next machine as quickly as possible. We thought we’d save time overall if everyone worked that way. However, when we considered the big picture, we discovered that spending more time on some processes could significantly reduce time on the next. Take roughing to finishing, for example. Instead of trying to rough faster, we focused on roughing better. A cavity may now spend more time in roughing, but it spends far less time in finishing. The net gain is significant.”

Building Out the Team

A good moldmaking team should not just consist of in-house personnel, it should also include technology suppliers. “They are the experts in their field and valuable partners,” Malenfant says. “The key is to maintain close relationships with them.”

For example, once Neovision started working closer with its local Delcam CAD/CAM reseller, it was able to identify inefficiencies in its processes. The reseller even recommended new methodologies and best practices that greatly reduced overall machining time. Training also taught the company how integrated stock models allow the software to identify remaining material and minimize manual user intervention. This results in optimum machining efficiency and saves even more time on finishing.

“The software’s unique approach to efficient area clearance and its ability to minimize sudden changes in cutting motion provide much better surface finishes,” Malenfant says. “This reduces most of the required handwork. The software also calculates constant cutter loads, which reduces tooling wear, enabling us to spend less on expensive tooling.”

Changes weren’t just made on the manufacturing floor; they extended to the design department as well. A more efficient shop floor was putting more pressure on Neovision’s designers to produce designs with more information in less time.

“We were faced with either hiring more designers or making the current team more efficient,” Malenfant says. “We opted for an investment in TopSolid this year, an integrated CAD/CAM. This enabled us to avoid new hires, complete designs in less time and improve communication.”

Neovision used a generic CAD package with some added tools for mold design, but it needed something better, faster, and that allowed for better communication with customers and the shop floor.

TopMold, Topsolid’s fully integrated, automated mold design solution, helped Neovision automatically calculate parting surfaces and parting curves, including allowances for areas containing drafts, and automatic separation of cores and cavities. Also beneficial is the software’s ability to easily generate coolant circuits, and its automatic drawing and BOM creation capabilities.

Malenfant also notes that, by using the kinematic tools in the software, Neovision is able to show mechanisms as they travel in 3D. By using the built-in collision avoidance tools, it is digitally proving out slides and lifters, ensuring that everything works before ever cutting steel.

“Saving time and avoiding costly mistakes helps us stay profitable on every tool, which is imperative,” Malenfant says.

When You Lose, You Win

“The North American moldmaking industry lost so much work to overseas competitors because we allowed our customers to believe molds were cheaper overseas,” he notes. “We failed our customers because we failed to understand our competition. We allowed price to become the deciding factor, and we lost. Many of our customers learned the hard way. It’s our job to make them see our value. We have to continually educate customers about the true cost of doing business overseas, and the real value we add as mold builders. Our knowledge and expertise is our greatest asset. Don’t give it away.”

With the Chinese molds, Warrior learned the hard way. The molds are inexpensive at first glance, but once all the extra costs are added in, you get a better understanding of the true cost of tooling. Warrior has brought back the majority of its tooling locally and only builds tools in China that don’t require a lot of handholding.

“Neovision never gave up on us, and, as a result, both companies gained from the experience,” says Rick Janisse, Warrior project engineer. “Warrior now benefits from lower overall tooling costs and improved overall quality. Neovision has become more of a partner now than just a supplier.”

Related Content

Top 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreStrategies for Delivering a Qualified Talent Pipeline for Manufacturers

Insights into the importance of talent in maintaining national competitiveness, the impact of global events on the workforce and practical strategies for developing and implementing effective talent plans.

Read MoreFAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

CAD/CAM Upgrade Boosts Shop’s Efficiency

CAD choice automates and animates, builds customer confidence through communication, and cuts design time in half.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More