Chicago Area Companies Give Students a "Tooling Start"

Moldmaking industry suppliers and shops support advanced manufacturing curricula in Chicago area high schools by donating products and scholarships.

It is wonderful to be on the receiving end of press releases, emailed notes and photos about companies in our industry that are doing their part to support advanced manufacturing curricula in elementary and high schools by donating products, scholarships and more. Recently I received all of the above from a couple of contacts I have, and I want to share them with readers today.

If you regularly read our MMT blogs, you know that workforce development is one of my favorite topics. The lack of skilled workers in moldmaking and closely-related trades has been an itch that needs scratching for too long, and that’s why it is so important to know that when local or federal legislators are not doing their part to boost U.S. manufacturing, many companies are stepping up and making an impact. Thank you to all of you who are. I want to hear about it!

Most recently, an email from Sean Soelter, president of V&S Tool in Schaumburg, Illinois, came to me with a photo attached and a note telling me he was pictured with Paul Wilhelm of OSG USA. Between them was a truck bed holding more than 500 new, donated cutting tools that will help many area high school students learn about advanced machining. Wilhelm says, “OSG has been doing tool donations to various high schools, colleges and vocational schools in the Chicagoland area for many years. We just re-vamped our program to reach more of the local educational community (especially high schools) and raise awareness about OSG’s products and potential employment opportunities while providing tools to these schools.”

OSG also recently announced the winners of its 2017 “Shaping Your Dreams” scholarship. This year’s recipients, Maram Safi of Elk Grove High School and Casey McCormick of Fenwick High School each received a $1,000 scholarship toward their education in their chosen fields. Maram would like to major in Mechanical or Electrical Engineering and Casey is targeting Mechanical Engineering. The students were presented with their awards at OSG’s Manufacturing Facility, located in Bensenville, Illinois. The “Shaping Your Dreams” scholarship program for 2018 will be announced this April and recipients will be chosen prior to the Fall semester 2018, according to Wilhelm. Watch for more details here on MMT’s blog web page.

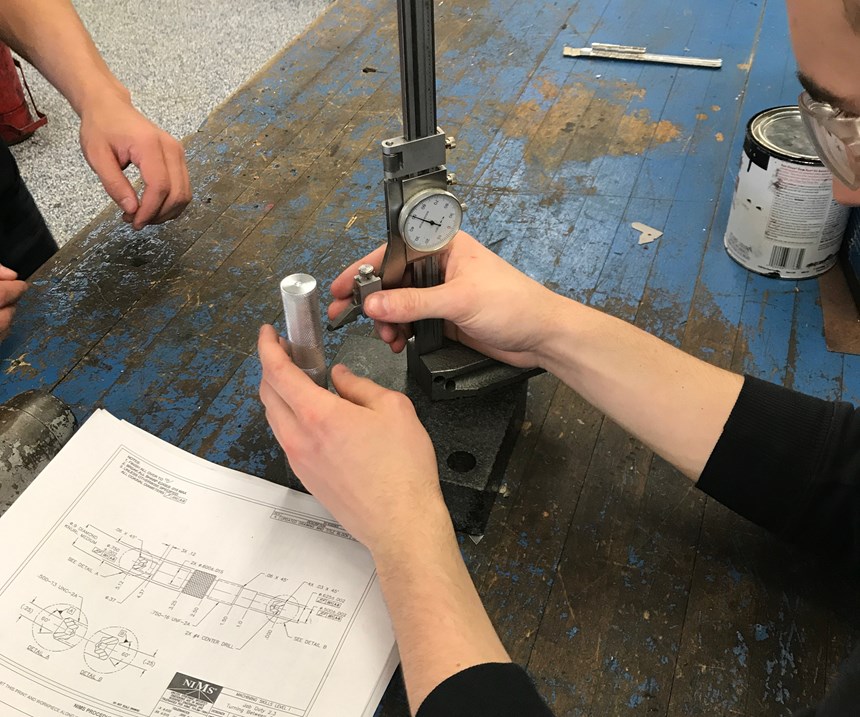

Last but not least, I was also in receipt of another photo showing Soelter’s pickup loaded down with grinding wheels that were donated by Quality Tools and Abrasives in Elk Grove Village. On his own, and in partnership with organizations like the American Mold Builders Association (AMBA) Chicago Chapter, the Technology and Manufacturing Association (TMA) in Illinois and other manufacturing-related entities, Soelter spends a lot of time driving around Chicagoland collecting donations, purchasing products (ideally at a discount) and meeting with groups who offer scholarships for schools with advanced manufacturing curricula to help defray the cost of items purchased. He also recently donated three vises and a height gauge to Cary Grove High School in Cary, Illinois.

We are all in this together and (in my humble opinion) our industry is one of the finest in the world, made up of people who truly care and want to help keep it strong for generations to come. Let’s keep working together like these companies and individuals are to make it happen! Happy Monday, all!

Related Content

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More