Amerimold Connects News: You Asked and We Answered!

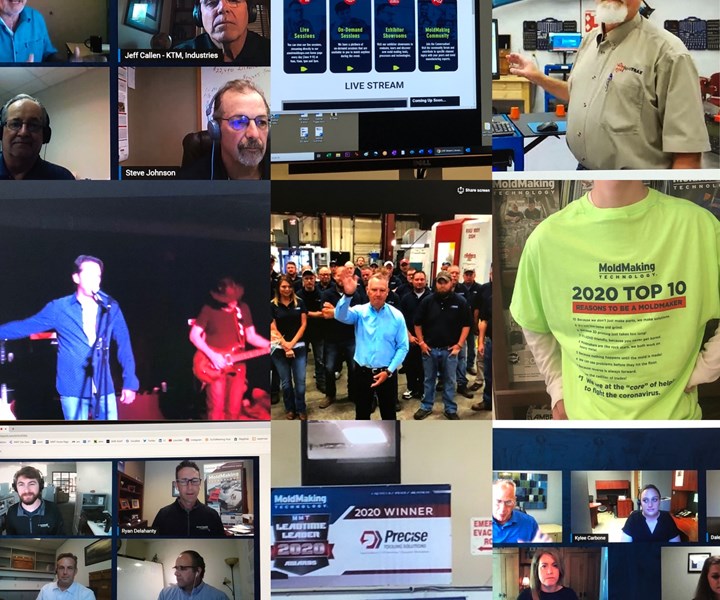

Amerimold Connects continues until Friday, June 19th! The MoldMaking Technology/Amerimold Expo community has never been shy about expressing its opinion, and we like that about you because that is how we learn and improve to serve you better.

Amerimold Connects continues until Friday, June 19th.

This past week many of you shared that despite Amerimold Connects offering free, limitless access to scheduled live-streaming presentations, demonstrations and commentary, on-demand educational content, access to technology supplier virtual “booths” and an online forum for the community to network, your teams need more time to take it all in due to the regular business of the day. So, we’ve extended access to the Amerimold Connects site through to this Friday, June 19th.

Here is a quick recap of the available content to remind you and your team to work your way over to the Amerimold Connects site to set up that MyPlanner and GET CONNECTING! (Perhaps, you can pick a few sessions and do a lunch-n-learn with the entire team … just an idea).

Lastly, thank you for your interest and support in what this remote event experience has to offer during these challenging times. If you have any questions, feedback or ideas, please feel free to reach out to me at cfuges@gardnerweb.com.

Supply Chain Management/Sourcing Sessions

- There Is A Better Way: Proven Method for Buying and Managing of a Mold

- The Importance of Reshoring Mold and Die Manufacturing

- Supply Chain Lessons from COVID-19 (Part I)

- Supply Chain Lessons from COVID-19: For Job Shops (Part II)

- Supply Chain Lessons from COVID-19: For OEMs (Part IlI)

- Supply Chain Lessons from COVID-19: How to Get Started with TCO (Part IV)

- What to Expect with USMCA and What’s Next for U.S. Trade Polic

COVID-19 Sessions

- The Importance of Leadership and Focus During and After COVID-19

- Liberty Molds Talks Respirators, Reshoring and Recommendations

- Remoting, Reaching Out and Ramping Up Recyclable PPE

- A Truly "Coronavirus" Collaborative Effort Puts Moldmaking, Manufacturing in the Spotlight

- Being Dynamic Amid Crisis

- The Cavalier Tool Army Takes on COVID-19

Workforce Development Sessions

- Cross-Generational Mentorship: Participants Share Their Journey

- Planning for the 2030 Workforce Challenge

- A Unique Approach to Filling Specific Workforce Needs

- On Demand content is broken down into tracks for easy searching: Engineer, Build, Maintain, Mold and Business and Current Events. These are available to view all week.

Strategies and Best Practices Sessions

- Quick Conversations Can Change the Course of Your Business

- Keeping Culture Change Constant and Consistent

- Data Plan, Leadership Teams and Continuous Improvement Culture

- The Magic of Manufacturing and Marketing

- Benefits and Challenges to Becoming a One Stop Shop

- 3-in-1 Moldmaking Force Always Looking for Problems ... to Solve

- Listening and Understanding Leads to Success

Design and Engineering Sessions

- Essential Design for Additive Manufacturing Principles

- Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

- Reduce Delivery Time and Increase Mold Quality

Machining, Cutting Tools, EDM, Automation, Mold Components, Hot Runner, Inspection & Measurement Sessions

- A Look at Tooling 4.0

- Digital Manufacturing in Action: Connecting Advanced Control Technology to Five-Axis Machining

- General-Purpose Holemaking Using Replaceable Insert Drill

- Consistent Tool Holding Practices for the Die-Mold Industry

- Custom Mold & Design Talks Hybrid Additive Manufacturing

- Achieve Repeatable Perfection with New Surface Grinding Technology

- Tackling Linear Movements in a Mold

- How to Machine an “Impossible Part” without EDM or Five-Axis Machining

- CNC Deep Hole Drilling With Milling

- Everything You Wanted to Know About Hot Runner Systems and How to Optimize Their Performance

- Integrated Technologies to Drive Costs Out and Improve Part Quality

Mold Maintenance, Repair and Surface Treatment Sessions

- Now You See It – Now You Don’t: The Magic of Dry Ice in Plastics, Rubber Industry Applications

- A Video Tutorial on How Advanced Laser Texturing Technology Works

- Working Remote? Add Visibility to Your Existing ERP System

- How to Correctly Diagnose Hot Runner Electrical Issues

- How to Safely Maintain Cooling Passages within Your Molds

- Improving Your Mold Handling Process

- Achieve Trouble-Free Molding with Precise, Turnkey Mold Technology Solutions

- From Mold Finishing to Welding to Repair: Experts Share Their Secrets to a Smoother Project

Related Content

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

Read MoreMore Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

Read MoreMoldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

Read MoreWhere Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More