Additive Manufacturing—in Space!!!

Wow! You can’t make this stuff up. Space manufacturing company Made in Space has partnered with NASA’s Marshall Space Flight Center to launch the first 3D printer to space.

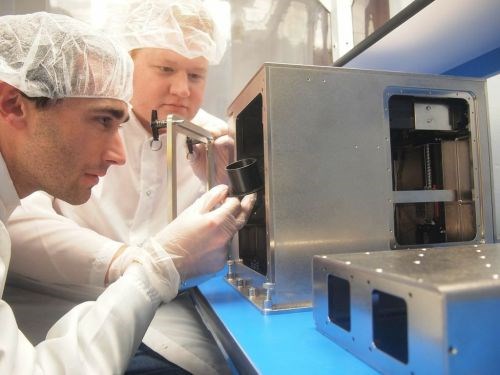

Made in Space’s customized 3D printer will be the first device to manufacture parts away from planet Earth. The 3D Printing in Zero-G Experiment will validate the capability of additive manufacturing in zero-gravity. “Imagine an astronaut needing to make a life-or-death repair on the International Space Station,” says Aaron Kemmer, CEO of Made in Space. “Rather than hoping that the necessary parts and tools are on the station already, what if the parts could be 3D printed when they needed them?”

All space missions today are completely dependent on Earth and the launch vehicles that send equipment to space. The greater the distance from Earth and the longer the duration, the more difficult it will be to resupply materials.

“As NASA ventures further into space, whether redirecting an asteroid or sending humans to Mars, we’ll need transformative technology to reduce cargo weight and volume,” NASA Administrator Charles Bolden said during a recent tour of the agency’s Ames Research Center at Moffett Field, Calif. “In the future, perhaps astronauts will be able to print the tools or components they need while in space.”

The Made in Space and NASA team envisions a future where space missions can be virtually self-sufficient and manufacture most of what they need in space. This includes such things as consumables, common tools, and replacements for lost or broken parts and eventually even such things as CubeSats (small, deployable satellites).

“The 3D printing experiment with NASA is a step towards the future. The ability to 3D print parts and tools on-demand greatly increases the reliability and safety of space missions while also dropping the cost by orders of magnitude,” says Kemmer. “The first printers will start by building test coupons, and will then build a broad range of parts, such as tools and science equipment.”

Both Made in Space and NASA view the space station as the place to initiate the journey of in-space manufacturing. I for one will be following this journey and will be watching as this story continues to unfold…

Related Content

-

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.