3D Design Software Reduces Cycle Time by 75 Percent and Increases Product Quality

Cool Pak chose SolidWorks® design software because it is easy to use, facilitates mold development and is fully integrated with the Gold Partner Certified CAMWorks™ machining system, which the company uses to run its CNC equipment to create tooling.

Share

Do you ever wonder where the blueberries and strawberries that you add to your morning cereal grew? Do you ever think about when your fresh produce was harvested, or how far it traveled to arrive at your local grocer? In all likelihood, the only questions that you have concerning produce are these: How fresh is it, and how good does it taste? Making sure that the answers to those questions are “very” and “great” is the job of Cool Pak LLC.

Bringing It In-House

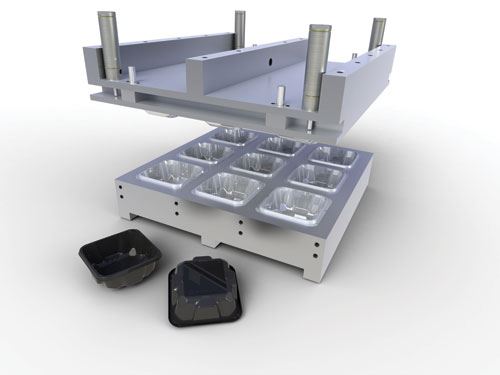

As a key supplier of packaging to growers, shippers, repackers and other food suppliers, the company designs and manufactures a variety of trays, tills, tubs, clamshells and domed containers that are used to package, transport and sell fresh produce. The company’s staff combines decades of experience in agriculture and packaging—acquired through its long family history of manufacturing and distribution in California—with a commitment to innovation in the design and production of packaging solutions.

Until recently, Cool Pak contracted its design and mold development work with outside consultants. However, as the company grew and customer demand for innovative and environmentally-friendly packaging solutions increased, Cool Pak needed to establish its own internal design capabilities, according to Product Development Manager Leo Lira.

“I was hired to build a department and transition product design and prototype mold development in-house,” Lira explains. “Cool Pak is growing as a company, and we need to increase productivity to compete successfully. We also need to address new requirements from our larger chain customers, such as giving them the opportunity to approve new designs in advance. New traceability regulations from governmental agencies also require us to have greater control of the process.”

Software Eases Transition

Cool Pak chose SolidWorks® design software because it is easy to use, facilitates mold development and is fully integrated with the Gold Partner Certified CAMWorks™ machining system, which the company uses to run its CNC equipment to create tooling.

Lira says that the combination of SolidWorks’ ease-of-use, mold design capabilities and its seamless integration with CAMWorks CAM software has given them a significant edge over their old process— Leo is seeing a 75 percent reduction in cycle time, and an increase in product quality.

SolidWorks’ ease-of-use means even new users can get up to speed quickly. But SolidWorks is also powerful enough to handle complex and intricate designs. And mold design functionality and surfacing capabilities are standard in the base package of SolidWorks.

In addition, SolidWorks has eight fully integrated CAM partners for customers to choose from to provide truly associative, seamless CAD/CAM integration. These CAM products run directly inside SolidWorks—make a change to the part, the mold updates, electrodes update and CAM toolpaths update—no export or import of data required. These are mainstream CAM companies that offer best-in-class capabilities. And since you have eight to choose from, you probably wouldn’t have to change CAM systems, and you certainly wouldn’t be stuck with a CAM system that was difficult to use just to get complete CAD/CAM integration.

“I felt that in order to build a department and get it up and running quickly, SolidWorks software was the obvious choice,” Lira says. “Because it is easier to learn and use—particularly for working with mold developers and creating prototypes—SolidWorks software was simply the logical solution.”

Added Benefits

By implementing SolidWorks software, Cool Pak can now handle in-house its design and prototyping needs, which have dramatically increased as the company has grown. In addition to ramping up throughput, SolidWorks software has helped Cook Pak to shorten customer response time, innovate new packaging and facilitate design changes.

“We are winning new business because we can show customers how they can ship more product with our packaging,” Lira notes. “With the combination of SolidWorks software and CAMWorks, our quality has increased, while our delivery times have decreased.

For example, with our patent-pending, tamper-evident packaging, we not only have eliminated steps from the manufacturing process, but also have developed a more space-efficient design that enables our customers to pack and move more produce in a single load.”

Using SolidWorks software, Cool Pak has greater control of the product development process, resulting in time savings, cost reductions and improved quality. The company uses SolidWorks software to generate all package designs and prototype molds, which manufacturing partners then use to produce packaging on a truly global scale.

“We’ve cut the time it takes to create a design and produce a prototype mold by 75 percent,” Lira stresses. “Being able to go from design to prototype within a week is a significant advantage, and we are doing it while improving quality and reducing material usage at the same time.”

Since implementing SolidWorks software, Cool Pak has made tremendous strides in producing containers that drastically increase shipping and packaging efficiencies, while lessening environmental impacts. By increasing the number of clamshells that can fit on a pallet and in a truck, the company helps customers reduce the amount of fuel required to deliver fresh produce to the marketplace. In some cases, Cool Pak has been able to reduce waste throughout the supply chain by over 35 percent.

The company primarily produces its clamshells from recycled PET plastic (RPET), with at least 85 percent of every clamshell containing RPET and some containing 100 percent RPET. Cool Pak has launched a number of programs for various companies, including Walmart and Trader Joe’s, using corn-based, biodegradable PLA material, and the company is developing new biodegradable plastics.

“With SolidWorks software, we have the tools we need to grow our business and develop the innovative green packaging solutions of tomorrow,” Lira says.

For More Information:

Dassault Systèmes / SolidWorks Corp.

(800) 693-9000

info@solidworks.com

solidworks.com

Geometric Technologies

(480) 367-0132

camworks.com

Cool Pak LLC

(805) 981-2434

cool-pak.com

Related Content

MMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More