2020 Sourcing & Technology Guide: Service Providers

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services. Introducing a brand new section this year: Service Providers.

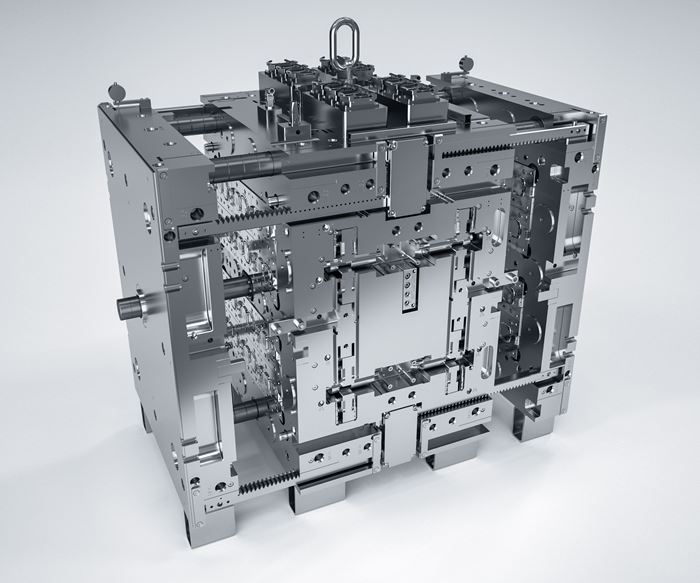

Image courtesy Creative Technology.

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services. Our online database offers more than 1,000 manufacturers, distributors and suppliers for more than 200 product and service categories that you employ daily. To keep this information current, MMT surveys and updates its supplier database every spring with the latest company contact information and product/service offerings. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 11 sections, including a brand new section this year: Service Providers.

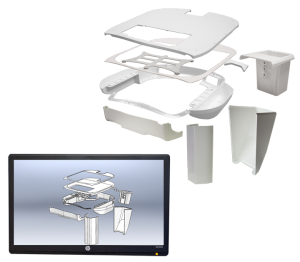

Due to the increased need for North American manufacturing capacity and capabilities since the onset of the coronavirus, we added a Service Providers section focused on suppliers of blow, compression, extrusion blow, foam, injection, liquid injection blow, stretch blow and thermoform molds, as well as die-cast, dies, prototype tooling and prototype/short-run/injection molding services.

This month’s Technology Review and Sourcing Guide includes a portion of that database listed in sourcing grids tailored to match suppliers with their respective product/service offerings along with a sample of product releases that the magazine featured throughout the year. These are the companies from the July 2020 Service Providers section:

A1 Tool Corporation — Melrose Park, IL, 708-345-5000

Aalbers Tool & Mold — Oldcastle, ON, Canada, 519-737-1369

Accede Mold & Tool Co., Inc. — Rochester, NY, 585-254-6490

Ameritech Die & Mold — Mooresville, NC, 704-664-0801

Armin Tool — South Elgin, IL, 847-742-1864

B A Die Mold — Aurora, IL, 630-978-4747

Byrne Tool — Rockford, MI, 616-866-4479

Cavalier Tool & Manufacturing, Ltd. — Windor, ON, Canada, 519-944-2144

CDM Tool & Mfg. Co. LLC — Hartford, WI, 262-673-5620

Chicago Mold Engineering Co., Inc. — St. Charles, IL, 630-584-1311

Commercial Tool & Die — Comstock Park, MI, 616-785-5400

Concept Molds, Inc. — Schoolcraft, MI, 269-679-2100

Creative Blow Mold Tooling — Lee's Summit, MO, 816-525-4220

Crest Mold Technology Inc. — Old Castle, ON, Canada, 519-737-1546

Custom Mold & Manufacturing Inc. — Milwaukee, WI, 414-384-6299

Dynamic Tool & Design — Menomonee Falls, WI, 262-783-6340

Electroform Co. — Rockford, IL, 815-533-4223

Extreme Tool & Engineering — Wakefield, MI, 906-229-9100

Industrial Molds — Rockford, IL, 815-397-2971

Intex Tooling Technologies — Aurora, ON, Canada, 289-840-1095

Janler Corp. — Chicago, IL, 773-774-0166

JMMS, Inc. — Easley, SC, 864-855-0450

Liberty Molds, Inc. — Portage, MI, 269-327-0997

M&M Tool and Mold LLC — Greenbay, WI, 920-336-6474

M.R. Mold & Engineering Corp. — Brea, CA, 714-996-5511

Max 3 LLC — Benton Harbor, MI, 269-925-2044

MGS Mfg. Group — Germantown, WI, 262-255-5790

Michael Tool & Mold Ltd. — Oldcastle, ON, Canada, 519-737-1269

Michiana Global Mold — Mishawaka, IN, 574-259-6262

Minco Tool & Mold, Inc. — Dayton, OH, 937-890-7905

Mold Craft, Inc. — Willernie, MN, 651-426-3216

Nypromold Inc. — Clinton, MA, 978-365-4547

Omega Tool Inc. — Menomonee Falls, WI, 262-255-0205

Precise Tooling Solutions, Inc. — Columbus, IN, 812-378-0247

R & D / Leverage — Lee's Summit, MI, 586-744-0881

Triangle Tool Corporation — Milwaukee, WI, 414-357-7117

United Tool and Mold Inc. — Easley, SC, 864-859-8300

Wepco Plastics Inc. — Middlefield, CT, 860-349-3407

X-Cell Tool Mold Inc. — Fairview, PA, 814-474-9100

Xcentric Mold & Engineering Inc. — Clinton Twp., MI, 586-598-4636

SERVICE PROVIDERS

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More