Surface Treatment

The Ionic Fusion Process

Touted as an alternative to plating, ionization makes mold components harder, more lubricious and corrosion resistant.

Read MoreElectrical Discharge Generator Breaks New Ground

A brand new EDM generator achieves a cutting speed of 400 mm}/min, or 37 square inch/hour, for the first time in the world, and achieves the feat of marrying the integrity of the surfaces machined with a high cutting speed.

Read MoreHow To Locate the Right Polishing and Plating Vendor

When it comes to polishing and plating, decide what your company needs most and then research your options.

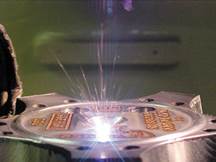

Read MoreLaser Engraving Enhances Mold Design

Consideration should always be given to the optimum cost/quality relationship when choosing laser engraving.

Read MoreHydrogen Embrittlement: How Small Details Can Have Large Effects

Knowing the facts about hydrogen embrittlement from the beginning will save both time and money down the road.

Read MoreMold Preservation and Maintenance for Ultimate Productivity

Making a mold last with as little downtime as possible is the ultimate goal of a plastic molding manager. By taking some early, preventive steps, moldmakers can extend the life of the mold and save money in the long run.

Read MoreKing Systems, Plastics Technology Division - Developing A Competitive Edge Never Ends

By investing in both technology and employee skills, King Systems, Plastics Technology Division, combines the customer service advantages of a small-sized moldmaker with the cutting-edge skills needed to succeed.

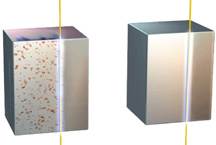

Read MoreEDM to a Shine With Silicon Powder EDM

A dual-tank, silicon powder process makes it possible to machine most tool steels to a highly reflective surface finish.

Read MoreSub-harmonic Stress Relief Improves Mold Quality

The quality of the mold lies mostly beneath the surface of the steel. By using sub-harmonic stress relief, moldmakers can improve mold quality - enhancing machine stability, long-term shape stabilization and the mold's resistance to cracking in service.

Read MoreSpecializing in Success

The members of MoldMaking Technology's Editorial Advisory Board express their views on the benefits of specialization to a moldmaker.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)