Molding Equipment

StackTeck Enhances Mold Qualification Capabilities

The moldmaker offers a virtual mold testing capability package for customers limiting travel during the pandemic, as well as for when future business resumes.

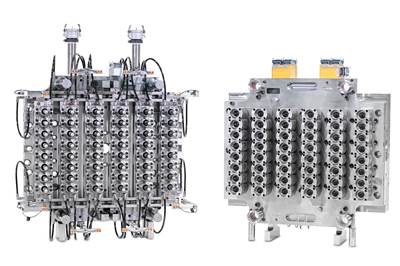

Read MoreAdaptive PET Preform Mold Meets Fluid Production Requirements

To meet continuously changing consumer demands, Husky highlights the NexPET system which supports a wider variety of applications, more SKUs, shorter production runs and more frequent design changeovers.

Read MoreMichigan Mold Builder Gets Business Savvy and Adds Vibration and Hot Plate Welding Services

Best Tool & Engineering identifies a new niche in vibration and hotplate welding and beefs up its business management skills.

Read More8 Mold Design Decisions That Impact Automation

Making the right decisions during eight key mold design phases will avoid automation problems and save money on price, installation and operation.

Read More8 Ways to Increase Mold Life

A checklist of molding machine settings and preventative maintenance actions that improve mold longevity.

Read MoreVIDEO: What Is Freeform Injection Molding?

FIM or freeform injection molding combines the proven injection molding process with the freedom of part design. Check out this video describing how this advanced technology works.

WatchCooling Solutions Portfolio Offers High Performance Cooling Capacity

Frigel will bring a complete portfolio of advanced cooling solutions for the plastics industry at K 2019.

Read MoreTooling Technologies Offer Value, Productivity and Flexibility

Husky will be running its new HyPET HPP5e system at K 2019, designed to delivering better energy savings, system reliability, preform quality and user friendliness.

Read MoreALBA Webinar Focuses on Molds In Motion

ALBA Enterprises, with MoldMaking Technology, will be hosting a webinar September 18 at 2:00 pm, offering a variety of unique solutions for movement in plastic injection molds and die-cast dies.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Watch