Maintain

Technology Roundup: Surface Treatment

Engraving systems, part polishing services, portable fiber laser marking units, ceramic super stones and more make up this month’s product/service compilation.

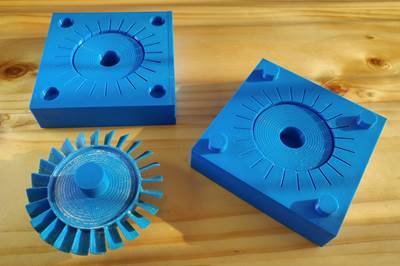

Read More3D-Printed Mold and Part Polishing Service Advances AM Geometry and Material Capabilities

Ultra Polishing extends its services for polishing 3D-printed plastic molds and parts and printed metals, for companies creating products with complex dimensions and using nontraditional materials.

Read MoreMobile Laser Engraver Adapted For Large Tooling

Alliance Specialties and Laser Sales’ Leviathan IPG Fiber Laser System retains a 360-degree rotation, and an extendable boom-arm attachment for greater accessibility to more difficult, harder-to-reach areas.

Read MoreCeramic Super Stones Cover New Grit Range for Semi, Final and Mirror Polishing

DW Sales offers new fine-grits abrasives to its line for optimal surface polishing.

Read MoreDual-Function Ultrasonic Polisher Capable of Demanding Polishing, Deburring Task Execution

Giving the versatility of both ultrasonic and mechanical polishing, the PCS Company Ultramax DF unit enables users to polish right up to the wall, or finish to an edge.

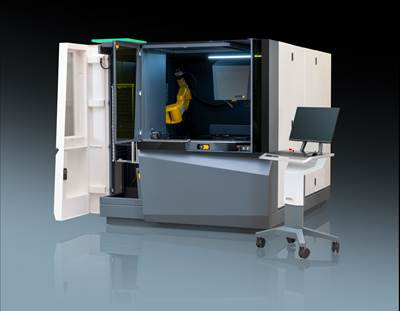

Read MoreArc Welding System Automates Weld Program Creation

Trumpf has release the TruArc Weld 1000. Equipped with a cobot, the system provides an automated alternative for parts users typically weld manually.

Read MoreMold Cleaner Line Eliminates Chlorinated Solvents

Reformulation of Slide Products’ Mold Cleaner Plus Degreaser 4 mold care line is made better for workers and the environment at an affordable cost.

Read MoreAll-In-One Fiber Laser Marking Unit Integrated into Portable System

Rocklin Manufacturing presents the MobiLase, a fiber laser marker housed in a lightweight suitcase that can delivers fast and durable laser markings directly at the part.

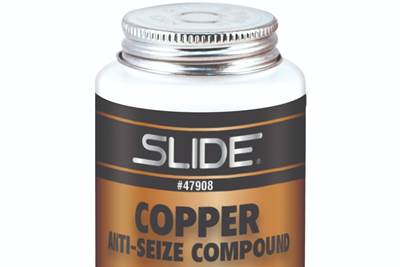

WatchCopper Anti-Seize Compound Facilitates Reuse of Damaged or Threaded Mold Components

Slide Products’ anti-size lubricant is formulated with a high level of metallic solids for increased performance, higher levels of temperature stability, performance and protection for mold components.

Read MoreTop-Loading, Electric Oven Heat Treats Components

Grieve’s top-loading oven features 6-inch insulated walls, 16-gauge aluminized steel interior and a bottom reinforced for 800-pound capacity.

Read More