Maintain

Camera-Assisted Laser System Verifies Quality Part Marking for Plastics, Moldmaking

The Foba M-Series laser marking workstations ensure almost error-free, economical direct part identification and reliable product traceability for automotive, tool and moldmaking, medical, plastic parts and more.

Read MorePTXPO 2023 Preview: Unlocking Your Next Solution for Mold Maintenance, Repair and Surface Treatment

PTXPO 2023 houses exhibitors that are ready to provide services and solutions for mold maintenance, repair and surface treatment challenges.

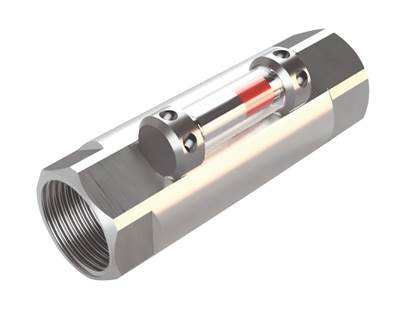

Read MoreInline Water Filters Keep Mold Cooling Channels Clean

Mouldpro filters, distributed in North America by Globeius Inc., are adept at dirt particles, rust or water scale deposits.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreConvenient Corrosion Protection for Proper Mold Care

Cortec’s EcoAir easy-to-use rust preventative spray enables injection molders and mold and die-makers to properly care for stored or in-use molds.

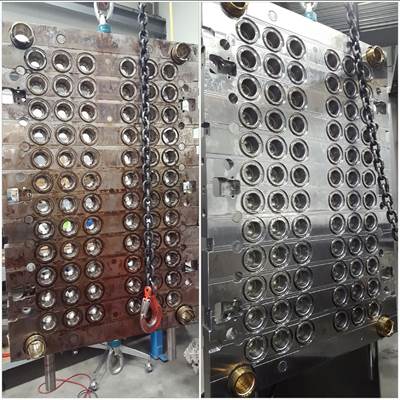

Read MoreUltrasonic Cleaning Equipment Cleans all Mold Sizes

Fisa North America brings nonabrasive cleaning to the mold maintenance forefront, removing oil, grease, colorants, gassing and more in as little as 20 minutes.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreAlkaline Formulation Confronts Difficult-to-Clean Operations

Madison Chemical’s Ultra-Clean US-159 removes aged, oxidized, burned-on oil and grease, including those commonly encountered during mold maintenance, repairs and rebuilds.

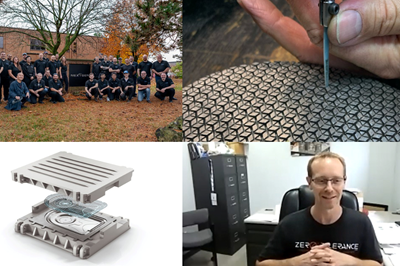

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read More

.jpg;maxWidth=300;quality=90)